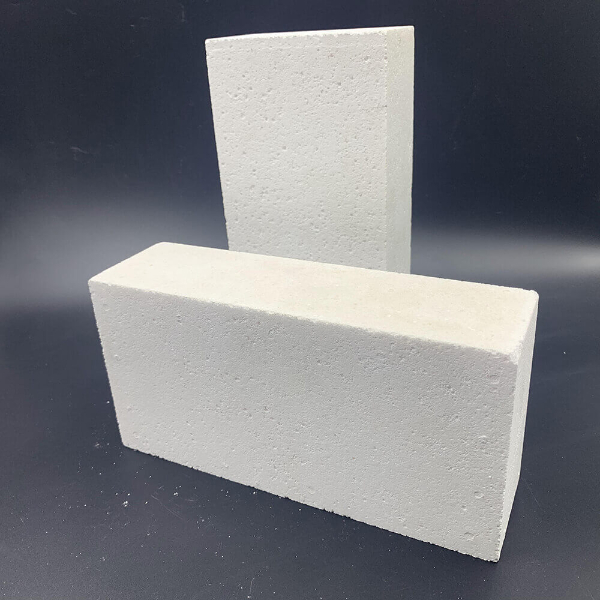

Alumina bubble brick is a high-quality thermal insulation material, which can be used as a kiln lining as an insulation layer, which can reduce the weight of the furnace body and optimize the kiln structure. The refractoriness of alumina bubble brick can reach more than 1750 degrees, and the thermal stability is good.

Parameters of alumina bubble brick

Fizikaviy va kimyoviy ko'rsatkichlar:

| Element | Indeks | ||

| LQZ99-1.4 | LQZ99-1.6 | LQZ99-1.8 | |

| Al2O3 % | ≥99 | ||

| SiO2 % | ≤0,3 | ||

| Fe2O3 % | ≤0,2 | ||

| Ommaviy zichlik g/sm3 | 1.3~1.5 | 1.5~1.7 | 1.7~1.9 |

| Sovuq maydalash kuchi MPA | ≥6 | ≥10 | ≥12 |

| Issiqlik o'tkazuvchanligi w /(m·K) Hot surface 1000℃ | ≤0,9 | ≤1.1 | ≤1.2 |

| Doimiy chiziqli o'zgarish darajasi % 1600℃ × 3h | ±0.3 | ||

| Element | Indeks | ||

| LQZ95-1.4 | LQZ95-1.6 | LQZ95-1.8 | |

| Al2O3 % | ≥95 | ||

| Fe2O3 % | ≤0,2 | ||

| Ommaviy zichlik g/sm3 | 1.3~1.5 | 1.5~1.7 | 1.7~1.9 |

| Normal temperature compressive strength MPa | ≥8 | ≥12 | ≥16 |

| Thermal Conductivity W/(m·K) hot face 1000℃ | ≤0,9 | ≤1.1 | ≤1.2 |

| Permanent Linear Change Rate % 1600℃×3h | ±0.3 | ||

| Element | Indeks | ||

| LQZ90-1.4 | LQZ90-1.6 | LQZ90-1.8 | |

| Al2O3 % | ≥90 | ||

| Fe2O3 % | ≤0,2 | ||

| Ommaviy zichlik g/sm3 | 1.3~1.5 | 1.5~1.7 | 1.7~1.9 |

| Normal temperature compressive strength MPa | ≥10 | ≥14 | ≥18 |

| Thermal Conductivity W/(m·K) Hot face 1000℃ | ≤0,9 | ≤1.1 | ≤1.2 |

| Permanent Linear Change Rate % 1600℃×3h | ±0.3 | ||

Advantages of alumina bubble brick

- Small volume density

- Past issiqlik o'tkazuvchanligi

- Usage temperature is above 1750℃

- Yuqori quvvat

- Can withstand the impact of high-temperature flame

- Save energy

- Acid and alkali corrosion resistance

Benefits of using alumina bubble brick

From the perspective of cost, the price of heavy bricks and hollow ball bricks is similar, and the price of alumina hollow ball bricks for particular areas may be slightly higher than that of heavy bricks. Still, in terms of weight, the use of hollow ball bricks can reduce the cost per cubic meter. 1-2 tons. Bundan tashqari, there is no need to make an insulation layer, which reduces the amount used and saves fuel. Not only is the use effect good but the cost is also reduced.

Application of alumina bubble brick

Alumina bubble brick is a commonly used thermal insulation material in the kiln, which plays a vital role in kiln construction and production. The volume density of alumina bubble brick is small, which can reduce the weight of the furnace body well, and has a good Insulation effect, which can save energy and raw material costs.

Rongsheng Group haqida

Rongsheng refrakter zavodi

Rongsheng refrakter zavodi

WeChat

QR kodini wechat orqali skanerlang