Yoriq pechida etilen ishlab chiqarishning yadrosi, va rezerozli materiallar - bu yoriq pechning xizmatidagi hayotga ta'sir qiluvchi muhim omil hisoblanadi. Ular orasida, SRT yorilish pechining astar va ishchi guruhi.

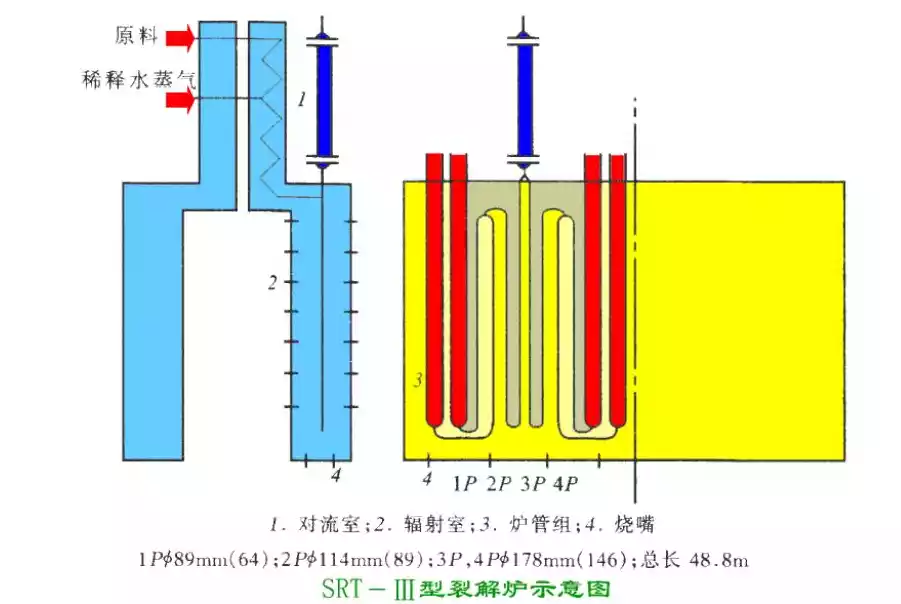

Srt cring pechlari

Srth yoriq pechlari uchun ob-havo

Yoriq pechining ichki yuqori harorati ostida, o'choqning devorini va pastki qismini qurish uchun repressorli g'isht ishlatiladi.

Refercer Castusiya:

Sovruza quyma kombinatlari kichik bo'shliqlar va pechlarning shikastlangan qismlarini to'ldirish va ta'mirlash uchun ishlatiladi.

Pechning izolyatsiya qatlami uchun ishlatiladi.

Piroliz pechasining tashqi qismida, Izolyatsiya g'ishtlari issiqlik o'tkazuvchanligini kamaytirish va issiqlik yo'qotilishini kamaytirish uchun ishlatiladi.

Termal to'siq qoplama:

Piroliz pechasining tashqi yuzalari issiq to'siq qoplamida qoplangan. Ushbu qoplamalar odatda keramik tolalardan qilingan, Qarzga chidamli tsement va boshqa materiallar, bu yaxshiroq issiqlik izolatsiyasini ta'minlaydi.

Kulolchilik tolali adyol

| Tasniflash harorati | 1140 | 1260 | 1400 | ||

| Baho | XT114 | XT126-a | XT126-b | XT140-a | XT140-B |

| Doimiy chiziqli o'zgaradi % ℃×24 soat | ≤ - 3 950 | ≤ - 3 1000 | ≤ - 3 1100 | ≤ - 3 1200 | ≤ - 3 1350 |

| Issiqlik o'tkazuvchanligi W/(m·K)500℃ | ≤0.153 | ||||

| Zinarli quvvat MPA 25 mm qalinlik | > 0.04 | > 0,05 | > 0.04 | > 0,06 | |

| Katta zichligi kg / m3 | 64/96/128/160 | ||||

| Al2O3 % | ≥44 | ≥45 | ≥45 | ≥52 | ≥36 |

| SiO2 % | ≥52 | ≥52 | ≥54 | ≥46 | ≥48 |

| Zro2 % | / | / | / | / | ≥15 |

| Fe2O3 % | ≤1,0 | ≤0,8 | ≤0,2 | ≤0,2 | ≤0,1 |

| Al2O3+SiO2 % | ≥96 | ≥97 | ≥99 | ≥99 | ≥ |

| Al2O3+SiO2+Zro2 % | / | / | / | / | 99 |

| Hajmi | 3600/7200× 610 × 20/0 / 50 | ||||

Sovuqli plastmassa

| Element | Kremniy karbidi | Zirkondium krom Korundum | ||

| Nmk4 | Nmk5 | Nmk6 | Nmk7 | |

| Al2O3 % | / | / | / | ≥80 |

| Sika % | ≥40 | ≥60 | ≥70 | / |

| Cr2O3 % | / | / | / | ≥3 |

| ZrO2 % | / | / | / | ≥2 |

| Katta zichlik g / sm3 110℃×24 soat | ≥2,4 | ≥2,5 | ≥2.6 | ≥2,8 |

| Doimiy chiziqli o'zgaradi % 1000℃ × 3h | -0.4~ 0 | -0.5~ 0 | -0.6~ 0 | -0.6~ 0 |

| Sovuq maydalash kuchi MPA 1000℃ × 3h | ≥60 | ≥70 | ≥80 | ≥90 |

| Xona haroratida qarshislikni kiying sm3 1000℃ × 3h | Lifol | Net | ≤5 | ≤5 |

| Issiqlik shokasi barqarorligi 1000 ℃ Suvni sovutish | ≥30 | ≥35 | ≥40 | ≥30 |

| Plastiklar indeksi % | 15~ 55 | |||

| Plastiklar /(m·K) 1000℃ | 3~ 5 | 5~ 7 | 6~ 8 | 2~ 3 |

| Maksimal xizmat harorati ℃ | 1400 | 1500 | 1600 | 1600 |

Yuqori alumina refrakteri

| Indeks | Yuqori alyumina bastakati | |

| Al2o3% | 65 | |

| SiO2% | 30 | |

| CAO%% | 6 | |

| Katta zichlik g / cm³ | 110℃,24r | 2.5 |

| 1350℃,24r | 2.6 | |

| Sovuq egilish kuchlari MPA | 110℃,24r | 6 |

| 1350℃,24r | 7.5 | |

| Issiq egilish kuchlari MPa | 110℃,24r | 45 |

| 1350℃,24r | 60 | |

| 1350 Chop etishning o'zgarishi tezligi | 0.2 | |

| Suv iste'moli miqdorini aralashtirish% | 10-12% | |

| Ishlash harorati | 1400 | |

Rongsheng refrakter zavodi

Rongsheng refrakter zavodi

WeChat

QR kodini wechat orqali skanerlang