Rongsheng can provide SK clay fire brick, which can be divided into SK32, SK34, SK36, SK38, and SK40 refractory bricks according to the brand. Refractory bricks are mainly used for furnace lining, flue, chimney, and other parts. The refractory bricks produced by our factory are wear-resistant, corrosion-resistant, anti-flaking, low creep, اچھا تھرمل جھٹکا استحکام, and the service life is 1.5 times that of ordinary products; they are mainly used in blast furnaces, گرم دھماکے کی بھٹی, carbon roasting furnaces, carbon calcining furnaces, کوک اوون, steel ladle, casting system, بوائلر, سیمنٹ کے بھٹے, glass kilns and various kiln linings and thermal equipment, وغیرہ, suitable for metallurgy, machinery, building materials, casting, ceramics, electricity, petroleum, chemical industry and other industries.

| آئٹم | SK-30 | SK-32 | SK-34 | SK-35 | SK-36 | SK-37 | SK-38 | SK-40 |

| AL203 % (≥) | 30 | 35 | 38 | 45 | 55 | 65 | 70 | 82 |

| Fe203 % (≤) | 2.5 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 |

| Softening temperature under load, 0.2MPa, C (>) | 1250 | 1350 | 1370 | 1420 | 1450 | 1480 | 1530 | 1600 |

| Porosity(%) | 22-26 | 20-24 | 20-22 | 18-20 | 20-23 | 20-23 | 20-22 | 18-20 |

| Density (g/cm³) | 1.9-2.0 | 1.95-2.1 | 2.1-2.2 | 2.15-2.22 | 2.25-24 | 2.3-2.5 | 2.4-2.6 | 2.5-2.7 |

| Normal temperature compressive strength, MPa (≥) | 20 | 25 | 30 | 40 | 45 | 50 | 60 | 70 |

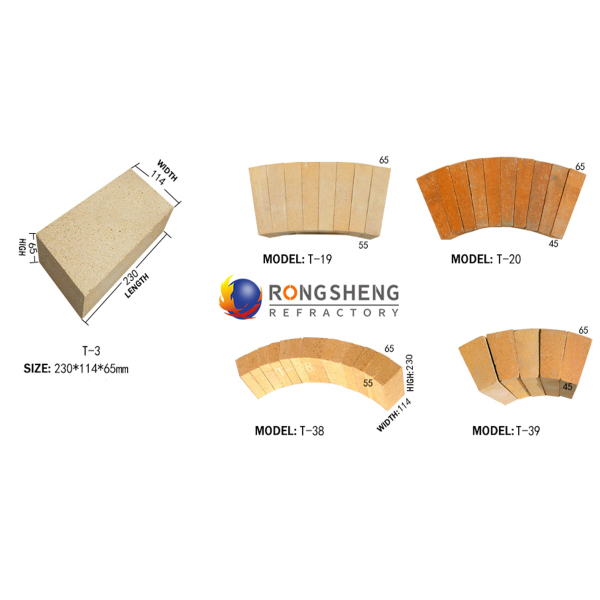

Sizes of Sk clay fire bricks

Sk clay fire bricks have standard brick sizes of 230*110*25M, and various special-shaped refractory bricks, including curved bricks, flow steel bricks, وغیرہ, which can also be customized according to your drawings.

Characteristics of SK clay bricks

- Excellent corrosion resistance and wear resistance;

- Good thermal shock resistance;

- Good anti-stripping and chemical corrosion resistance;

- Price advantage compared with high alumina bricks

- Excellent thermal performance and acid resistance;

- Good dimensional stability at high temperature;

- High mechanical strength;

SK clay brick production process

The main raw materials for making lightweight clay bricks are lightweight clay aggregate and clay powder, and the burnt material is sawdust. The raw materials are crushed and pulverized before mixing in a mixer. The order of adding materials: first add lightweight aggregate and clay, dry mix for 2 minutes, then add water, wet mix for 6 minutes, and then discharge. The moisture content of the mud is 17~20%.

After the mud is trapped for 24 hours, it is formed by a friction brick press. The bricks are dried in a tunnel dryer and fired in a downdraft kiln. The high firing temperature is 1250℃, and it is kept warm for 4 hours. It can be discharged from the kiln after natural cooling for 24 hours.

Uses of SK refractory bricks

SK30 fire clay bricks

SK30 bricks are mainly used for the lining of general heating furnaces, روٹری بھٹوں, بوائلر, ordinary kilns, and other industrial kilns with low working temperatures. The refractoriness of SK30 bricks is relatively low and is suitable for occasions with low-temperature requirements.

SK32 fire clay bricks

SK32 bricks are used for furnace linings that require slightly higher temperatures, such as glass kilns, ceramic kilns, lime kilns, وغیرہ. SK32 bricks have a slightly higher refractoriness than SK30 and are suitable for medium-temperature applications.

SK34 clay fire bricks

SK34 bricks are used in high-temperature kilns such as steelmaking furnaces, aluminum alloy furnaces, and heat treatment furnaces in the petrochemical (boiler) industry. They are suitable for use at higher temperatures and have good resistance to chemical corrosion.

SK36 refractory clay bricks

SK36 bricks are widely used in high-temperature equipment such as blast furnaces, گرم دھماکے کی بھٹی, and sintering furnaces in steel (blast furnace, electric furnace, ladle), petrochemical, گلاس, سیمنٹ, اور دیگر صنعتوں. They have high thermal shock resistance and refractoriness and are suitable for use in higher temperatures and complex chemical environments.

SK38 fire-resistant bricks

SK38 bricks are used for linings in extremely high temperatures and harsh environments, such as electric arc furnaces, high-temperature calciners, and other specialized high-temperature equipment. SK38 bricks have the highest fire resistance and chemical resistance, making them suitable for processes requiring extremely high temperatures and extreme conditions.

Our refractory brick factory

Our customers visit

رونگشینگ ریفریکٹریز فیکٹری

رونگشینگ ریفریکٹریز فیکٹری

WeChat

وی چیٹ کے ساتھ کیو آر کوڈ اسکین کریں۔