Yalıtım tuğlalarını kullanırken nelere dikkat etmelisiniz??

The use of kiln insulation bricks requires special attention to a series of factors to ensure their safe and efficient operation. Here are the key things to note when using kiln insulating fire bricks.

Yalıtım tuğlalarını kullanırken nelere dikkat etmelisiniz??

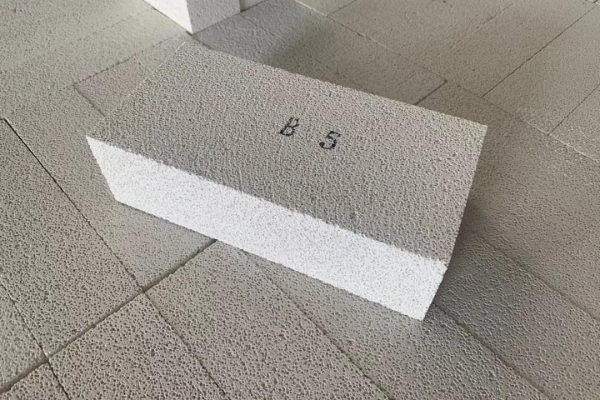

Quality inspection of insulation kiln bricks

Before installation, carefully check the quality of the insulating fire bricks. Make sure each brick has no visible damage, cracks, or other defects. Bricks should be replaced if found to be defective.

Correct installation

Make sure the insulating kiln bricks are installed correctly on the inside walls of the kiln, using appropriate high-temperature resistant adhesives and fixing materials.

Thermal cycling adaptability

Make sure the insulating fire bricks you choose have good thermal cycle adaptability. Kilns experience temperature rises and falls during operation, and insulating bricks need to be able to adapt stably to these thermal cycles.

Aşınma direnci

Since kiln operation may involve friction and wear of materials, ensure that the insulation bricks have sufficient wear resistance to extend their service life.

Temperature range

Make sure that the operating temperature range of the selected insulating bricks meets the actual operating temperature requirements of the kiln. Different types of insulating fire bricks have different high-temperature resistance capabilities.

Maintenance and inspection

Regularly inspect and maintain insulating fire bricks, remove dust and debris from the surface, and repair or replace damaged bricks promptly.

How to choose the right kiln insulation bricks

- For temperatures below 1000°C, diatomite bricks, expanded perlite bricks, vesaire. are mainly used as insulation layers for thermal equipment.

- Refractory and insulating bricks with a service temperature of 1000~1500℃ mainly include lightweight clay bricks, lightweight silica bricks, lightweight high alumina bricks, vesaire.

- It can be directly used as the lining of high-temperature kilns when the operating temperature is above 1500°C, mainly including lightweight corundum bricks, alumina hollow ball products, Ve zirconia hollow ball ürünler.

Rongsheng Refrakter Fabrikası

Rongsheng Refrakter Fabrikası

WeChat

QR Kodunu wechat ile tarayın