Sillimanit, doğal bir yüksek dereceli refrakter mineraldir, düşük termal genleşme oranının özelliklerine sahiptir, Metalurjik cüruf ve çeşitli cam sıvıların korozyon direnci, ve iyi yüksek sıcaklık aşınma direnci. Sillimanit tuğlasının fiziksel ve kimyasal özellikleri yüksek aluminalı tuğlalar, 1770-1830 ° C'lik bir refrakterlik ve 1500-1650 ° C'lik bir yük yumuşatma başlangıç noktası ile.

Sillimanit Tuğla Detayları

| öğe | indeks | |

| GXS60 | GXS65 | |

| Al2Ö3 % | ≥60 | ≥65 |

| SiO2 % | ≤36.5 | ≤32.5 |

| Fe2Ö3 % | ≤1.0 | ≤0,8 |

| Yığın yoğunluğu g/cm3 | ≥2,45 | ≥2.50 |

| görünür gözeneklilik % | ≤16 | ≤16 |

| Normal sıcaklık basınç dayanımı MPa | ≥80 | ≥90 |

| 0.2MPa Yük Yumuşatma Başlangıç Sıcaklığı ℃ | ≥1640 | ≥ |

Sillimanit tuğlaların avantajları

- Termal genleşme oranı. Sillimanit, son derece düşük termal genişlemeye sahip doğal bir yüksek dereceli refrakter mineraldir

- Yük altında yüksek yumuşama sıcaklığı. Yük altında yumuşatmanın başlangıç noktası 1500 ° C-1650 ° C'dir, yüksek sıcaklıkta iyi termal stabilite ile

- Güçlü cüruf direnci. Metalurjik cüruf ve çeşitli cam sıvılara karşı direnç

- Kimyasal korozyon direnci. Cam sıvıya çok az kirlilik

Sillimanit tuğlalar üretmek için hangi ekipmana ihtiyaç vardır?

Sistemi oluşturma. Hidrolik presin kullanılması, Kalıp için bir bilgisayar kontrol programı.

Malzeme sistemi. Orana göre, Otomatik toplu ve doğru tartma.

Karıştırma sistemi. Çıkış uçları olmadan eşit olarak karıştırmak için eğimli bir açılı bir mikser kullanın.

Ateşleme sistemi. 1800'e ulaşabilen ultra yüksek sıcaklık tünel fırını benimseyin.

Sillimanit tuğlaların uygulanması

Esas olarak cam havuz fırın akış deliklerinin kalıplanması için kullanılır, Blast fırın astarı, Fırın Boğazı, ve seramik endüstriyel fırın mobilyaları. Öncelikle doğal sillimanitten oluşan refrakter malzemeler de bu avantajlara sahiptir. Öyleyse, Sillimanit refrakterleri metalurjide yaygın olarak kullanılır, kimyasal, ve yapı malzemeleri endüstrileri.

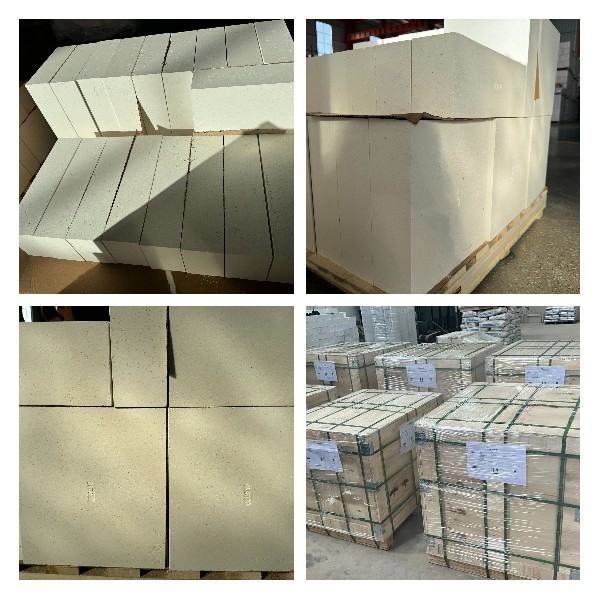

Özelleştirilmiş Sillimanit Refrakter Tuğlaları Destekleyin

Sillimanit refrakter tuğla, cam fırınlar için önemli bir refrakter malzemedir. Rongsheng, farklı şekillerde refrakter tuğlaları özelleştirebilir. Özel şekilli refrakter tuğlalara ihtiyacınız varsa, Bize tuğlaların boyutunu ve çizimini göndermelisiniz ve onları üreteceğiz.

Rongsheng Refrakter Fabrikası

Rongsheng Refrakter Fabrikası

İhtiyacım var 2 Sillimanit bloklarında 60 X 80 x 10mm. Ben de çalışabilirim 3 sayıca 40 X 80 X 10 ilave olarak.

Lütfen tedarik edebilir misin?

Gozo Glass Limited

Office@gozoglass.com

Merhaba, sizinle iletişime geçtik, lütfen e-postanızı kontrol edin, sorunuzu gönderdiğiniz için teşekkür ederiz