The difference between ceramic paper and ceramic cloth

Ceramic paper and ceramic cloth are both refractory materials made of ceramic fibers, but they have significant differences in structure, performance, and application.

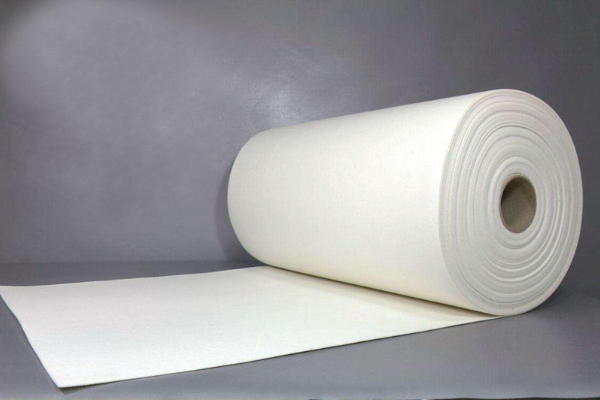

Ceramic fiber paper

Ceramic fiber paper is produced from high-purity ceramic fibers plus a small amount of scientifically selected and strictly controlled binding agents. The wet vacuum forming process makes the fiber distribution very uniform, and the thickness and volume density of the aluminum silicate fiber paper can also be strictly controlled; the binding agent will be completely ablated during use.

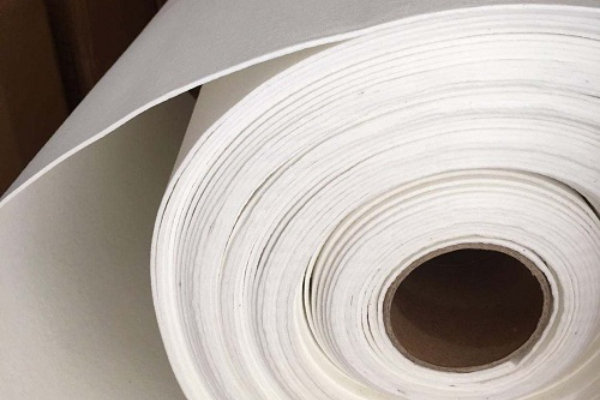

Ceramic fiber cloth

Ceramic fiber cloth is made of twisted ceramic fiber yarn reinforced with heat-resistant alloy wire or alkali-free glass yarn. Ceramic fiber cloth products have high strength, good flexibility, and strong processability. They not only have high-temperature insulation properties but also have the flexibility of ordinary textiles. It can be processed into various industrial and civil fire-resistant and heat-insulating products such as fire-proof clothing, fire-fighting blankets, and thermal insulation covers.

5 differences between ceramic fiber paper and ceramic fiber cloth

- Appearance. Ceramic fiber cloth is woven from ceramic fiber yarns intertwined with warp and weft lines, and has an obvious grid shape with a larger grid; ceramic fiber paper is formed by vacuum filtration and does not have a grid shape.

- Density. The density of ceramic fiber paper is 200 kg/m³, and the density of ceramic fiber cloth is 500 kg/m³. The density of ceramic fiber paper is smaller than that of ceramic fiber cloth.

- Thickness. Ceramic fiber paper can be as thin as 0.5mm and as thick as 10mm. The thickness of ceramic fiber cloth is relatively limited. Generally, the thinnest is 2mm and the thickest is 5mm.

- Supportiveness. Ceramic fiber paper has a certain degree of support and can be placed upright on the mold like a board; ceramic fiber cloth is like the cloth we use in daily life, it is very soft, cannot stand upright, and has no support.

- Tear resistance. Ceramic fiber paper has a certain toughness due to the addition of organic matter, but it can be torn by hand; ceramic fiber cloth cannot be torn.

Common characteristics of ceramic fiber paper and cloth

- High-temperature resistance, the operating temperature range of fiber paper and cloth type high-temperature insulation gasket is about 1000℃

- Low thermal conductivity, low heat capacity, excellent thermal insulation performance

- Good mechanical processing performance can be cut, cut, sheared, sawed, and punched

- The fiber is flexible, resilient, and has good sealing performance

- The slag ball content is low and will not wear the flat surfaces on both sides of the high-temperature heat insulation gasket.

- Stable chemical properties, anti-corrosion, long service life

Ceramic fiber paper and cloth application areas

- Industrial insulation, sealing, heat-insulating gaskets, such as petrochemical, metallurgical heating furnaces, high-temperature pipeline flange high-temperature sealing

- Molten metal seal cast aluminum model lining

- Anti-sintering isolation gaskets for ceramic-fired parts, release pads for ceramic glass and hot-melt (curved) glass, and release paper

- Sealing and thermal insulation of high-temperature components in the automotive industry, sound-absorbing and thermal insulation materials for mufflers, and thermal insulation liners for exhaust pipes

- Furnace door and furnace body expansion joint filling gasket

- Denitrification catalyst production line thermal insulation gasket

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Scan the QR Code with wechat