คณะกรรมการแคลเซียมซิลิเกตส่งออกไปยังปากีสถาน

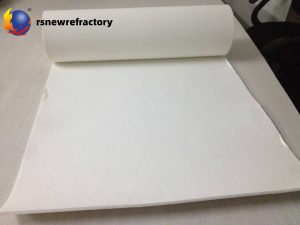

วัสดุทนไฟ Rongsheng Materials successfully exported a batch of high-performance calcium silicate boards to Pakistan. The customer is a company engaged in kiln manufacturing and maintenance. This company focuses on designing and maintaining industrial kilns, especially improving and enhancing kiln insulation systems. This is our first cooperation with this customer. The process of the project from initial communication to final delivery was very smooth. We will keep in touch for long-term cooperation.

Pakistani customer needs

Pakistani customers have strict performance requirements for kiln insulation materials. In order to optimize the insulation effect of their kilns, reduce heat loss, and improve energy utilization, customers need an insulation material that can work stably for a long time in a high-temperature environment. After many discussions, the customer finally chose the calcium silicate board product provided by Rongsheng. The customer is particularly concerned about the material’s high-temperature resistance, การนำความร้อนต่ำ, and good compressive strength to ensure that it can provide a lasting insulation effect during the operation of the kiln.

Characteristics of calcium silicate insulation board

- ทนต่ออุณหภูมิสูง: It can withstand temperatures up to 1000°C, ensuring that the kiln is not damaged under long-term high-temperature operation.

- Excellent thermal insulation: การนำความร้อนต่ำ, which can effectively reduce heat loss and improve kiln energy efficiency.

- Lightweight and pressure-resistant: It is not only light in weight, and easy to transport and install but also has high strength and can maintain stable mechanical properties in high-temperature environments.

Arrange order production and delivery

After the customer confirms the order, the Rongsheng factory immediately arranges production to ensure that the product can be delivered on time. The calcium silicate board undergoes strict quality inspection in the factory to ensure that all physical and chemical properties meet the customer’s requirements. After production is completed, we use protective packaging to ensure that the product will not be damaged during long-distance transportation. The entire order was shipped to Pakistan by sea and arrived smoothly within the time specified by the customer.

โรงงานทนไฟ Rongsheng

โรงงานทนไฟ Rongsheng

วีแชต

สแกน QR Code ด้วย wechat