Protect the molten steel from oxidation when it flows into the crystallizer from the tundish, evenly distribute the molten steel into the crystallizer, and control the flow state of the molten steel in the crystallizer, with good slag resistance, anti-blocking, long service life, and low accident rate.

Submerged nozzle physical and chemical indicators

Physical and chemical indicators:

| Нущта | Мазмун | |||

| JSK55 | JSK50 | JSK45 | JSK40 | |

| Ал2O3 % | ≥55 | ≥50 | ≥45 | ≥40 |

| В % | ≥16 | ≥18 | ≥20 | ≥22 |

| Flexural Strength MPa | ≥5.5 | ≥5.5 | ≥5.5 | ≥5 |

| Apparent porosity % | ≤19 | ≤19 | ≤19 | ≤19 |

| Bulk density g/cm3 | ≥2.36 | ≥2.32 | ≥2.28 | ≥2.18 |

Slag Area:

| Нущта | Мазмун | |||

| Z75 | Z70 | Z65 | Z55 | |

| Сиро2 % | ≥75 | ≥70 | ≥65 | ≥55 |

| В % | ≥9 | ≥12 | ≥15 | ≥18 |

| Apparent porosity % | ≤21 | ≤21 | ≤21 | ≤22 |

| Bulk density g/cm3 | ≥3.6 | ≥3.5 | ≥3.4 | ≥3.2 |

Introduction to the production process of the submerged entry nozzle

The production process of submerged nozzles requires various raw materials to be mixed into a uniform composite powder, which is then isostatically pressed into the desired shape of the green body. This is then sintered at high temperature to form a product with a certain strength, which is then shaped and processed into the required size. Finally, after inspection, it is packaged and shipped out.

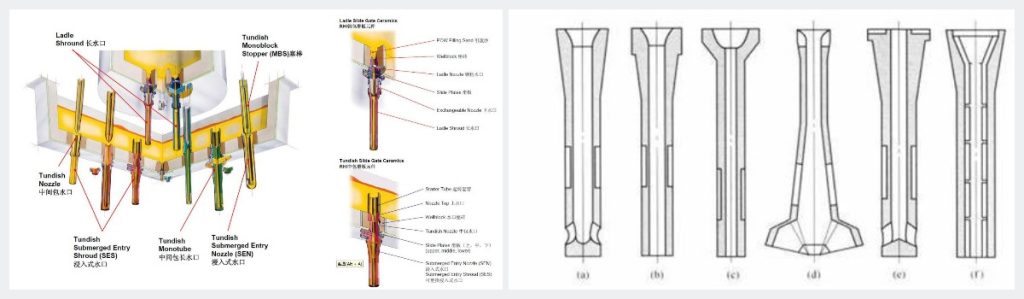

Structure type of submerged entry nozzles (SEN)

Submerged entry nozzles can be broadly categorized by their appearance and internal structure, as shown in the figure below.

Type A is a submerged nozzle with two or four side holes; Type B is a straight-through submerged nozzle; Type C is a submerged nozzle with a hemispherical bowl-shaped mouth, a combined nozzle used in conjunction with a tundish nozzle; Type D is a thin-walled, irregular-shaped submerged nozzle, typically used for thin slab continuous casting; Type E has a flat end face, typically a quick-change nozzle; Type F has a zirconium core embedded within it, used for billet continuous casting.

What conditions does the submerged nozzle need to meet?

1) Ensure the flow rate of molten steel at normal pulling speed.

(2) Make the heat flow distribution in the mold and the cross section of the ingot as uniform as possible;

(3) Facilitate the rapid melting of protective slag;

(4) Facilitate the floating of inclusions without slag rolling;

(5) Avoid violent turbulence of the steel liquid level in the crystallizer;

(6) Easy to install.

Selection of immersed nozzle material

In the early stage of continuous casting, the fused quartz immersion nozzle with good thermal stability and high purity can meet the casting of ordinary carbon steel, low manganese steel, aluminum killed steel and other steel types. Аммо, it is severely corroded under the conditions of high manganese steel and high alkalinity slag. At this time, the aluminum carbon immersion nozzle is widely used. The raw materials of aluminum carbon immersion nozzle are special grade bauxite, fused corundum or sintered corundum, ва ғайра., with the addition of graphite and antioxidants. The product has the advantages of corrosion resistance and thermal shock resistance.

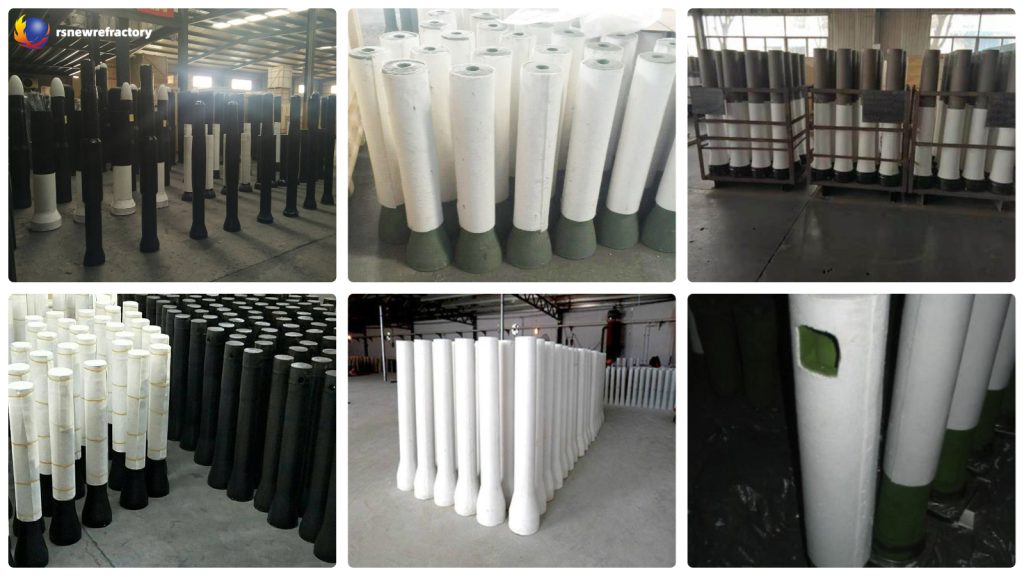

Rongsheng company introduction

Rongsheng Company is a professional supplier of refractory materials, with 12+years of export experience, exporting to more than 80 countries. The main products of Rongsheng Company include various Хрикҳои пешгирӣ, масолехи ба оташ тобовар бешакл, масолехи металлурги, thermal insulation materials, and so on.

Заводи рефрактори Ронгшен

Заводи рефрактори Ронгшен

WeChat

Коди QR-ро бо wechat скан кунед