Коэффициент ингредиентов маг -углеродных кирпичей

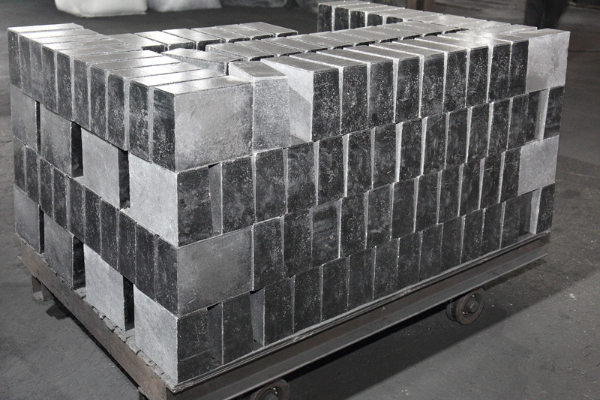

Маг -углеродные кирпичи - это рефрактерный материал, изготовленный из магнезийского песка и искусственного графита в качестве основного сырья, с определенным количеством антиоксидантов и связующих, and other auxiliary materials added through high-temperature sintering. It has the characteristics of high strength, strong impact resistance, высокая термостойкость, хорошая термостойкость, и т. д., and is widely used in high-temperature fields such as steel smelting and non-ferrous metal smelting.

Introduction to the proportion of magnesia carbon bricks

The main raw materials of магнезиальные углеродные кирпичи include magnesia sand, artificial graphite, antioxidant, связующее, and other auxiliary materials.

- Artificial graphite is another main raw material, accounting for about 15-35% of the total ingredients. Its function is to improve the electrical and thermal conductivity of magnesium carbon bricks, enhance antioxidant capacity, and improve corrosion resistance.

- Magnesium carbon bricks are susceptible to oxidation in high temperature environments, so a certain proportion of antioxidants needs to be added. Commonly used antioxidants include aluminum powder, графит, ammonia water, и т. д., accounting for about 1-5% of the total ingredients.

- Binders are important components that bond raw materials together through sintering reactions. Commonly used binders include phenolic resin, graphene, lithium carbonate, и т. д., accounting for about 1-5% of the total ingredients.

- According to specific needs, magnesium carbon bricks can also add some auxiliary materials, например, антикоррозионные средства, reinforcing agents, alkali metal compounds, и т. д., to improve their specific performance characteristics.

Use of mag carbon bricks

The proportion of ingredients in refractory magnesia carbon bricks has an important influence on its quality and performance. The proportion of each raw material needs to be strictly controlled to meet different usage requirements. In the process of using magnesia carbon bricks, it is also necessary to pay attention to the correct use method to extend its service life and make it play a better refractory performance.

Завод огнеупоров Ронгшэн

Завод огнеупоров Ронгшэн

WeChat

Отсканируйте QR-код с помощью wechat