The main content of silicon carbide bricks is SIC, and its content reaches 72%-99%. Silicon carbide refractory bricks can be combined with clay, oxide, and silicon nitride in different ways. The characteristics of its response and the industry of application are also different.

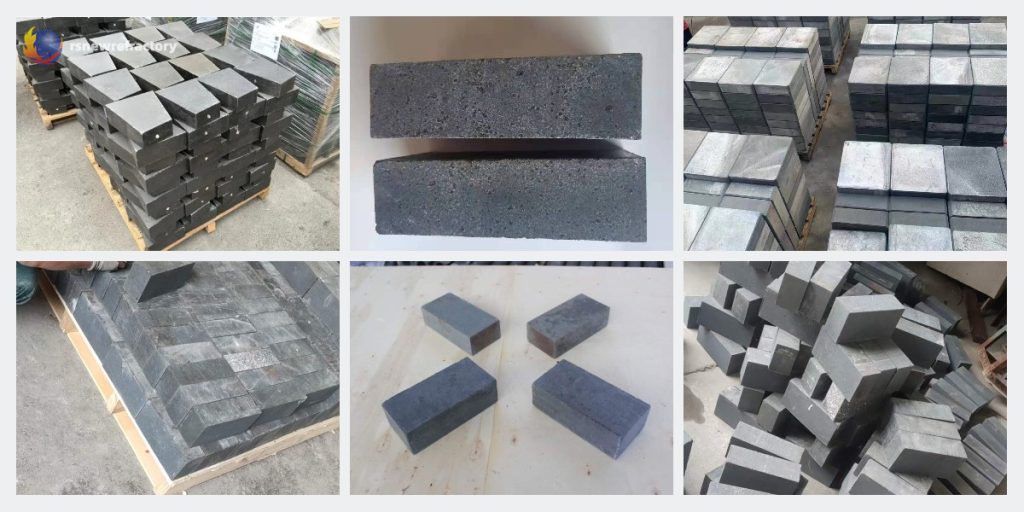

Silicon carbide brick

| Articol | Bonding Type | |||||||

| Lut | Mullite | SiO2 | Si3N4 | Sialon | β-SiC | R-SiC | Siliconizing reaction | |

| Sic % | >85 | >70 | ≥90 | ≥72 | ≥71 | ≥94 | ≥99 | ≥80 |

| Si3N4 % | / | / | / | ≥20 | / | / | / | / |

| Al2O3 % | / | / | / | / | ≥5 | / | / | / |

| Si % | / | / | / | / | ≥5.5(N) | / | / | 12~18 |

| Densitate vrac g/cm3 | 2.5~2.6 | 2.55~2.65 | 2.6~2.7 | ≥2.65 | ≥2.65 | ≥2.63 | ≥2.65 | ≥3,0 |

| Porozitate aparentă % | ≤20 | ≤16 | ≤15 | ≤16 | ≤16 | ≤17 | ≤15 | ≤0,5 |

| Flexural strength at room temperature MPa | ≥20 | ≥25 | ≥25 | ≥45 | ≥45 | ≥30 | ≥90 | ≥220 |

| Flexural strength at high temperature MPa 1400℃ | / | / | / | ≥45 | ≥45 | ≥30 | ≥90 | ≥240 |

| Cold Crushing strength MPa | ≥100 | ≥100 | ≥120 | ≥160 | ≥150 | ≥140 | ≥300 | ≥800 |

Features of silicon carbide bricks

- Rezistență la coroziune

- Slightly large

- Conductivitate termică bună

- Strong impact resistance

- Low thermal expansion coefficient is a high-quality high-temperature resistant material

Types of silicon carbide bricks

Classification by combination method

Silicon carbide refractory bricks can be divided into clay-bonded silicon carbide bricks, β-silicon carbide bonded silicon carbide bricks, silicon oxynitride bonded silicon carbide bricks, silicon nitride bonded silicon carbide bricks, and Sialon bonded silicon carbide bricks according to different bonding methods.

Classification by chemical content

According to the different contents of chemical components, silicon carbide bricks are mainly divided into oxide-bonded silicon carbide bricks, green silicon carbide bricks, corundum silicon carbide bricks, mullite silicon carbide bricks, and high alumina silicon carbide bricks.

Application of silicon carbide brick

- Used in the metallurgical industry

The metallurgical industry mainly uses aluminum melting furnaces for aluminum alloy smelting, secondary tuyere bricks for blast furnaces, etc. - Used in the power industry

În industria energetică, it is mainly used in boilers and is set at the nozzle of the boiler combustion chamber. - Used in the waste disposal industry

Silicon carbide bricks can also be used in waste incinerators

Introducere companiei Rongsheng

Rongsheng Company is a professional supplier of Materiale refractare, cu 10 ani de experiență în export, exportând în mai mult de 80 ţări. Principalele produse ale companiei Rongsheng includ diverse cărămizi refractare, materiale refractare neformate, materiale metalurgice, materiale termoizolante, și așa mai departe.

Customer visit display

Fabrica de refractare Rongsheng

Fabrica de refractare Rongsheng

WeChat

Scanați codul QR cu wechat