Mortarul refractar este transformat în noi tipuri de materiale de liant anorganic, alegând aceleași materiale de pulbere și adăugând un liant anorganic, Conform cererii de materiale de construcție. Există patru note sub NT-1300, NT-1400, NT-1500, și NT-1600, Fiecare material este împărțit în greutate ușoară și grea, Și putem alege mortarul refractar relevant în funcție de diferite cereri de materiale de construcție.

Parametrii mortarului refractar

MgO(%) | Al2O3(%) | Cr2O3(%) | Module de ruptură(MPa) | Refractaritatea | Timp de legătură | Țăran | ||

| ≥ | ≥ | 110℃ *24H | 1400℃ *3H | (℃) ≥ | (min) | |||

| Mortar-crom-magnezie | 78-85 | – | 3-5 | – | 2 | 1800 | 1-3 | Sticlă de apă |

| Mortar compozit cu magnezie-crom | 90 | – | 1-3 | – | 4 | 1800 | 1-3 | Sticlă de apă |

| Magnesia Mortar | 85-90 | – | – | – | 3 | 1800 | 1-3 | Sticlă de apă |

| Mortar spinel | 80-85 | 4-8 | – | – | 4 | 1800 | 1-3 | Sticlă de apă |

| Mortar de alumină mare | – | 60-75 | – | 1 | 4 | 1790 | 1-3 | Apă |

| Mortar anti-stripping de alumină | – | 75 | – | 1 | 5 | 1790 | 1-3 | Apă |

| Mortar fosfat | – | 70 | – | 1 | 5 | 1790 | 1-3 | Fosfat |

| P901 MORTAR | – | 75 | – | 1.5 | 6 | 1790 | 1-3 | Fosfat |

| Mortar rezistent la alc | – | 30-35 | – | 1 | 3 | 1690 | 1-3 | Apă |

| Izolând mortar rezistent la alcalin | – | 30-40 | – | 1 | 1.5 | 1650 | 1-3 | Apă |

| Noroi de siliciu(RSGN-96) | SiO2%≥96 | 0.6 | – | 0.5 | 1.5 | 1710 | 1-3 | Apă |

| Noroi de siliciu(RSGN-94) | SiO2%≥94 | – | – | 1 | 3 | 1690 | 1-3 | Apă |

| Noroi de izolare de căldură din siliciu(RSGGN-94) | SiO2%≥94 | – | – | 0.5 | 1.5 | 1690 | 1-3 | Apă |

| Noroi de izolare de căldură din siliciu(RSGGN-92) | SiO2%≥92 | – | – | 0.5 | 1.5 | 1670 | 1-3 | Apă |

| Mortar refractar rezistent la uzură | – | – | – | – | 1000℃*3h(4-6) | 1790 | 1-3 | Apă |

| Mortar refractar ușor | – | – | – | – | – | 1650 | 1-3 | Apă |

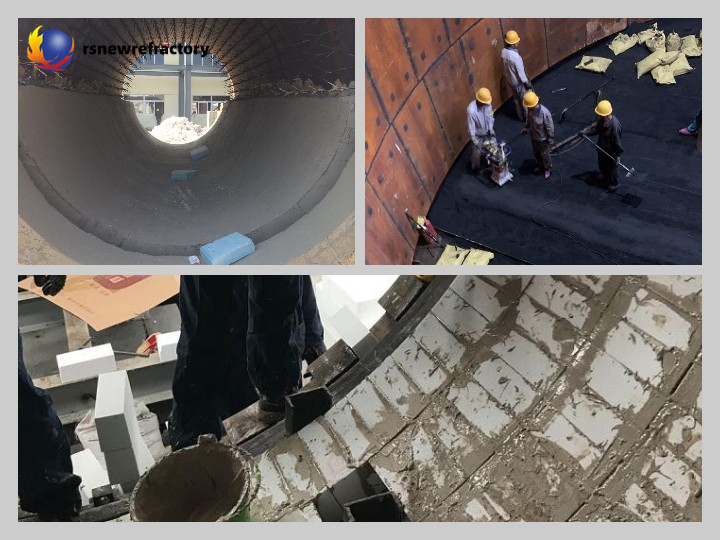

Aplicarea mortarului refractar

Industriile de aplicare includ metalurgia, materiale de construcții, utilaje, petrochimice, sticlă, cazane, energie electrică, oţel, ciment, etc. Materialul mortarului refractar trebuie să fie în concordanță cu cel al produselor refractare de zidărie. Pe lângă faptul că este folosit ca material de indicare, nămolul refractar poate fi folosit și ca strat protector pentru căptușeli prin acoperire sau pulverizare.

Caracteristicile mortarului cu căldură ridicată

Siguranţă: Mortarul nu produce scântei atunci când este afectat sau frecat, și este deosebit de potrivit pentru medii cu substanțe inflamabile și explozive.

Rezistent la uzura: Are o rezistență excelentă la uzură, poate rezista eficient la diverse uzură, și extinde durata de viață a podelei.

Anti-alunecare: Suprafața sa este netedă și are proprietăți anti-alunecare bune, ceea ce poate reduce eficient accidentele.

Anti-static: Mortarul are proprietăți conductoare bune, ceea ce poate preveni eficient acumularea statică a energiei electrice și poate evita pericolele potențiale.

Construcție convenabilă: Poate fi adăugat direct cu apă și agitat proporțional, iar operația de construcție este simplă și convenabilă.

Protecția mediului: Mortarul nu conține substanțe chimice dăunătoare corpului uman și mediului, și îndeplinește cerințele de protecție a mediului.

Procesul de construcție a mortarului refractar

- Curatenie de baza. În primul rând, este necesar să curățați suprafața fundației pentru a evita resturile precum praful și uleiul plutitor.

- Suprafata de constructie umeda. Înainte de aplicare, utilizați o rolă sau un stropitor pentru a umezi suprafața, dar nu trebuie să existe exces de apă în timpul aplicării.

- Configurați materialele. Amestecați mortarul și apa, si adauga apa la 14-20%, in functie de situatia reala.

- Neteziți suprafața. Mortarul agitat se toarnă pe planul de operare, care trebuie completat în termen 20 minute.

- întreținere. Stropiți cu apă după reparație, sau acoperiți cu folie de plastic pentru întreținere.

De ce să alegeți compania refractară monolitică Rongsheng

Linie de producție complet actualizată automată

Rongsheng are o linie de producție complet actualizată automată, care poate realiza producția automată de produse amorfe, cum ar fi ciment refractar, turnabile refractare, Mortar refractar, etc., și realizează o producție de înaltă calitate și eficientă de Materiale refractare.

Serviciu de inginer profesionist

Avem o echipă de ingineri cu experiență, care pot oferi clienților soluții refractare profesionale pentru a asigura cea mai bună utilizare a produselor.

Capacitate puternică de aprovizionare din fabrică refractară

Rongsheng refractar are două fabrici refractare. Rongsheng este capabil să furnizeze în mod stabil un număr mare de produse refractare monomer. Mai important, a exportat materiale refractare la mai mult de 50 țări și are experiență bogată în export.

Produse refractare de înaltă calitate

Rongsheng va controla strict calitatea produsului, care oferă clienților o asigurare a produselor de înaltă calitate. În același timp, Putem personaliza materialele refractare pentru clienți.

Fabrica de refractare Rongsheng

Fabrica de refractare Rongsheng

PENTRU 50 SAC DE KILOS DE CASTEL REFRACTAR DE CÂȚI LITRI DE APĂ AVEM NEVOIE+584121968090

Bine,te vom contacta in cel mai scurt timp posibil