Caracteristici ale cărămizilor de verificare a sobei cu explozie fierbinte

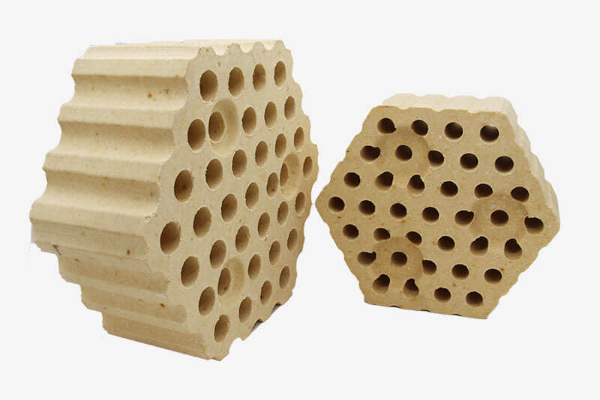

Cărămizile checker sunt cărămizi refractare care pot fi utilizate în regeneratoarele furnalelor și sobelor calde.. Sunt utilizate pe scară largă în industria oțelului. Cărămizile Checker au o capacitate puternică de schimb de căldură, aerisire lină, rezistență mică, și o zonă mare de stocare a căldurii.

Introducerea cărămizilor de caroserie

Verificatoarele refractare sunt utilizate în principal în regenerarea sobelor cu explozie fierbinte. Gazul poate trece prin găurile superioare și inferioare ale damelor refractare. În sobe încinse, diferite cărămizi refractare vor fi selectate în funcție de cerințele de temperatură în diferite regiuni și alți indicatori, precum cărămizi de lut și cărămizi cu conținut ridicat de alumină, cărămizi de mullit, și cărămizi de sillimanit.

Cum funcționează cărămizile?

Funcția sobei este de a încălzi aerul rece trimis în furnal în aer cald, iar aerul cald este trimis în furnal prin conducta de aer cald pentru reacția de ardere. Soba caldă de furnal are o perioadă de ardere a cuptorului și o perioadă de alimentare cu aer, iar cele două cicluri de lucru alternează. În perioada de tragere, gazele de ardere la temperatură înaltă după ardere trec prin găurile cărămizilor de tip checker ale sobei cu suflare fierbinte și transferă căldură la verificatoarele refractare. În perioada de alimentare cu aer, aerul rece de la suflantă intră în soba caldă, este încălzit de cărămizile checker pentru a deveni aer fierbinte, și este trimis la furnal prin conducta de aer cald.

Comparația zonei de stocare a căldurii a cărămizilor de tip checker cu diferite dimensiuni

- Cărămidă tradițională cu zăbrele cu 7 găuri: diametrul grilei 43 mm, suprafata de stocare a caldura 38,1m2/m3

- 7-gaură cărămidă zăbrele de înaltă eficiență: diametrul rețelei este de 30 mm. Suprafața de stocare a căldurii este de 47,08 m2/m3

- 19-cărămidă checker de înaltă eficiență, diametru grilă 30mm suprafață de stocare a căldurii 48,6m2/m3

- 31-cărămidă checker de înaltă eficiență, diametru grilă 25mm suprafață de stocare a căldurii 58.1m2/m3

- 37-cărămidă checker de înaltă eficiență, diametru grilă 20mm suprafață de stocare a căldurii 68,7m2/m3

Fabrica de refractare Rongsheng

Fabrica de refractare Rongsheng

WeChat

Scanați codul QR cu wechat