What are the application areas of anti-corrosion and acid-resistant bricks?

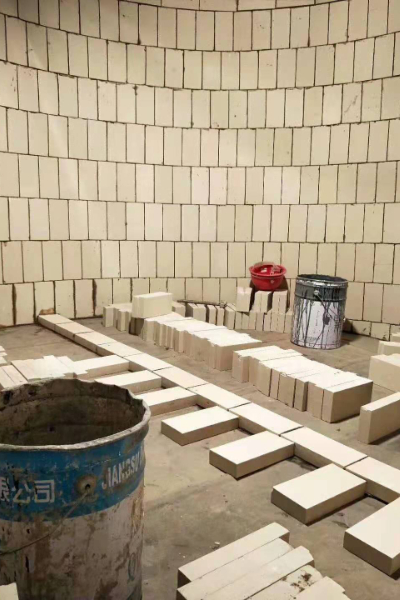

Anti-corrosion and acid-resistant bricks are anti-corrosion ceramic tiles with excellent acid resistance. Their main features are high corrosion resistance, durability, and stability in acidic environments. Due to these characteristics, acid-resistant bricks are widely used in various buildings and facilities in acidic environments, including production workshops and warehouses in the chemical, farmaceutic, alimente, beverage, și alte industrii. Acid-resistant bricks can be divided into acid-resistant standard bricks și acid-resistant ceramic tiles according to their appearance.

Acid-resistant bricks used in the chemical industry

În industria chimică, acid-resistant bricks can be used for equipment, conducte, and floors that manufacture and store acidic chemicals. Since acidic chemicals are highly corrosive to materials, the use of acid-resistant bricks can ensure the durability and stability of equipment, conducte, and floors, reduce the frequency of maintenance and replacement, and improve production efficiency.

Anti-corrosion and acid-resistant bricks used in the pharmaceutical industry

In the pharmaceutical industry, acid-resistant bricks can be used for equipment, conducte, and floors for manufacturing and storing drugs. Many drugs are produced in acidic environments, so the use of acid-resistant bricks can ensure the corrosion resistance and cleanliness of equipment, conducte, and floors, and ensure the quality and safety of drugs.

Acid-resistant bricks are used in the food industry

In the food and beverage industry, acid-resistant bricks can be used in equipment, pipes, and floors for manufacturing and storing food and beverages. Food and beverages often contain acidic substances. The use of acid-resistant bricks can prevent these substances from corroding equipment, pipes, and floors, ensuring the quality and safety of food and beverages.

Precautions for using chemical bricks

When using acid-resistant bricks, you need to pay attention to the following points. Primul, you should choose acid-resistant bricks and accessories that meet your needs, taking into account factors such as the size, weight, and use environment of the equipment. În al doilea rând, when laying chemical bricks, you should follow the construction specifications to ensure that the gaps between bricks are as small as possible to improve corrosion resistance. în plus, in daily use, acid-resistant bricks should be regularly maintained and cleaned to maintain the cleanliness and glossiness of their surface. The correct selection and use of acid-resistant bricks can improve the durability and stability of equipment and ensure production efficiency and product safety.

Fabrica de refractare Rongsheng

Fabrica de refractare Rongsheng

WeChat

Scanați codul QR cu wechat