Refractory Blankets Shipped to Singapore

Our client is a well-known industrial furnace manufacturing company located in Singapore, mainly serving the steel, petrochemical, energy, and other industries in Southeast Asia. They need to purchase a batch of refractory blankets. They saw our website on Google, found us, and sent an inquiry.

Singaporean customers’ demand for refractory blankets

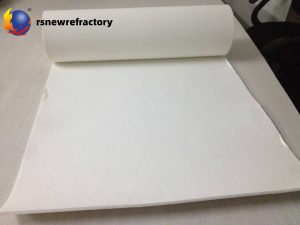

Singaporean customers want to find a ceramic fiber blanket with stable quality and excellent performance for the lining and insulation layer of their high-temperature industrial furnaces. Specific requirements include:

- High refractoriness: Able to withstand temperatures up to 1260°C and above.

- Low thermal conductivity: Excellent thermal insulation performance in high-temperature environments, reducing heat loss.

- High tensile strength: Able to maintain stable shape during installation and use, and not easy to break.

- Environmentally friendly and safe: The material is non-toxic and harmless and meets international environmental standards.

Successful cooperation on ceramic fiber blankets

Through initial communication and sample testing, contract signing and production arrangements, logistics and transportation, as well as after-sales service and technical support, we successfully exported ceramic fiber blankets to Singapore and successfully applied them to multiple high-temperature industrial projects of customers.

The purpose of customers buying ceramic fiber refractory blanket

- Industrial furnace lining: The customer’s high-temperature industrial furnace needs to operate at extremely high temperatures. As the lining material, ceramic fiber blanket provides excellent thermal insulation effect and fire resistance, ensuring the stability and safety of the furnace structure.

- Heat treatment furnace insulation layer: During the heat treatment process, it is crucial to maintain a uniform and stable high-temperature environment. The ceramic fiber blanket serves as a thermal insulation layer, effectively reducing heat loss and improving the efficiency and quality of the heat treatment process.

- High-temperature pipeline insulation: The customer’s production process involves high-temperature fluid transportation, and ceramic fiber blankets are used for external insulation of high-temperature pipelines, which significantly reduces heat energy loss and improves the thermal efficiency of the system.

- Thermal insulation of chemical equipment: During the petrochemical production process, customers need to provide thermal insulation protection for reactors and high-temperature equipment. The low thermal conductivity and high refractoriness of the ceramic fiber blanket meet its strict thermal insulation requirements and ensure the safety and efficiency of production.

- High-temperature seals: Customers also use ceramic fiber blankets to manufacture high-temperature seals, which solves the sealing problem of equipment during high-temperature operation and improves the overall performance and life of the equipment.

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Scan the QR Code with wechat