What is a ladle sliding nozzle?

The ladle sliding nozzle is an important structure to control the flow of molten steel in the ladle. During the process of molten steel from ladle to tundish and from tundish to crystallizer, it is necessary to ensure that the steel flow is compact and concentrated and to minimize the contact between molten steel and the atmosphere to reduce oxidation.

Sliding nozzle system introduction

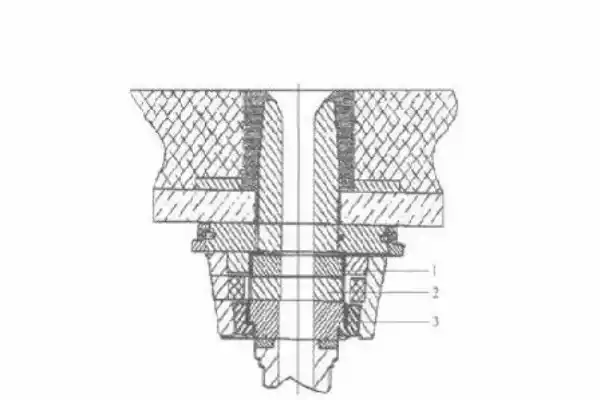

The sliding nozzle system, aquilo é, the flow steel system (collectively referred to as the flow control system) that combines the upper nozzle, the slide plate, and the lower nozzle (submerged long nozzle), realizes the sealed steel flow and minimizes the risk of secondary oxidation of molten steel. With the development of continuous casting technology and secondary refining technology, the sliding nozzle system has become more and more important in the modern iron and steel smelting process and has become an indispensable part of smelting.

What requirements do ladle sliding nozzles need to meet?

Em primeiro lugar, it is required to have sufficient strength at high temperatures to withstand the static pressure of molten steel, and secondly, the sliding surface of the upper and lower slides must be very smooth with high flatness to ensure tight contact and no leakage of molten steel during the pouring process. It is also resistant to erosion, e corrosão, and has good thermal stability, so as to be able to withstand sudden changes in temperature, erosion of molten steel, and erosion of slag.

Ladle sliding nozzle material

Aluminum carbon and aluminum zirconium carbon are mainly used, which can basically meet the needs of ordinary steel continuous casting. No entanto, when the carbon-containing slide plate is heated, carbon oxidation occurs, and the carbon loss behavior will cause the slide plate to react with slag, reaming, grinding, erosion, steel infiltration, etc., and finally manifests as flow steel hole destruction and surface corrosion. Portanto, sliding nozzles and sliding bricks are consumables and need to be replaced frequently to ensure production safety.

Importance of ladle sliding nozzle

- Improve smelting efficiency: The precise flow control of the sliding nozzle helps to improve the accurate batching and adjustment of molten steel, ensure the efficient operation of the smelting process, and improve smelting efficiency and output.

- Guarantee steel quality: The stable flow control of the sliding nozzle can ensure the uniform quality and composition of molten steel, reduce uneven mixing and inclusions, and improve the stability and consistency of steel quality.

- Improve operational safety: the precise control of the sliding nozzle reduces the risk of the operator and reduces the occurrence of operating errors and accidents

Fábrica de Refratários Rongsheng

Fábrica de Refratários Rongsheng

WeChat

Escaneie o código QR com o wechat