Massa de compactação neutra para fornos de indução

Os revestimentos neutros são os materiais refratários mais populares e amplamente utilizados em fornos de indução devido ao seu alto ponto de fusão., força elevada, alta dureza, alta resistência ao desgaste, alta resistência à corrosão, e consumo calculado por tonelada de aço produzida.

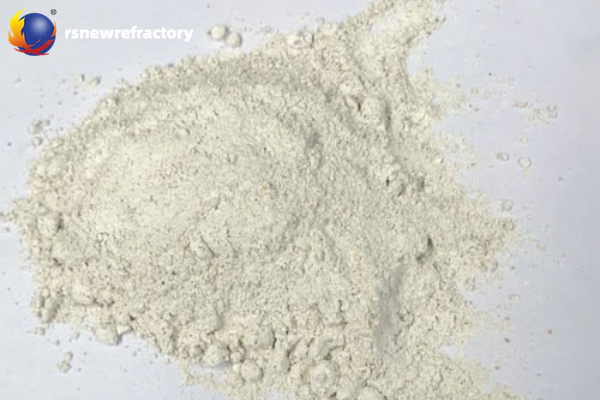

What is neutral ramming mass?

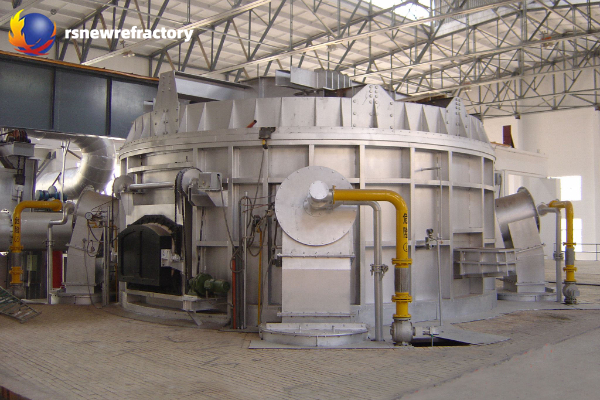

Neutral ramming mass is a chemically neutral refractory material, whose main components are neutral raw materials such as alumina (Al₂O₃), mulita (3Al₂O₃·2SiO₂), and fused corundum. This material can maintain good stability at high temperatures and has strong corrosion resistance to acidic and alkaline molten metals. The main use of neutral ramming mass in induction furnaces is as a lining material to protect the metal shell of the induction furnace and extend the service life of the equipment.

Main characteristics of neutral ramming mass

Strong chemical stability

Ramming mass has high resistance to chemical erosion of acidic and alkaline molten metals and can be widely used in smelting a variety of metals and alloys.

Excellent high-temperature performance

The refractoriness of neutral ramming mass is usually above 1700°C, and it can be used for a long time in a high-temperature smelting environment without softening or deformation.

Easy construction

Ramming mass is constructed by mechanical or manual ramming, without the need for prefabricated bricks or complex installation processes, with high construction efficiency and strong adaptability.

Good thermal shock stability

Due to the low thermal expansion coefficient of the material, neutral ramming mass exhibits good thermal shock resistance during the rapid heating and cooling of the induction furnace, which can effectively prevent the furnace lining from cracking or peeling.

Longa vida útil

The refractory ramming mass has strong resistance to slag erosion and wear, which can significantly extend the service life of the furnace lining and reduce the replacement frequency.

Excellent refractory material for induction furnace

Neutral ramming mass is an ideal choice for induction furnace lining due to its excellent chemical stability, high-temperature performance, and convenient construction. It can not only extend the service life of the induction furnace, but also improve production efficiency and reduce maintenance costs. With the advancement of industry technology, the performance and application scenarios of refractory ramming mass will continue to expand, bringing more possibilities for the development of the metallurgical and foundry industries.

Fábrica de Refratários Rongsheng

Fábrica de Refratários Rongsheng

WeChat

Escaneie o código QR com o wechat