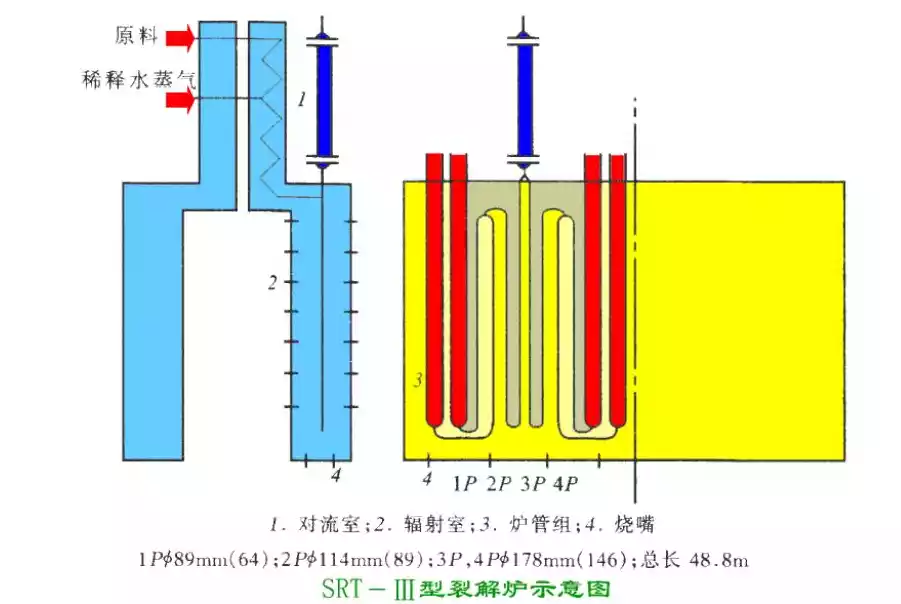

O forno de craqueamento é o núcleo da produção de etileno, e o material refratário é um fator importante que afeta a vida útil do forno de craqueamento. Entre eles, o revestimento e o grupo de trabalho do forno de craqueamento SRT usam materiais refratários.

Forno de craqueamento SRT

Refratários para forno de craqueamento SRT

Na área interna de alta temperatura do forno de craqueamento, tijolos refratários são usados para construir a parede e o fundo do forno.

Castables refratários:

Os concretos refratários são usados para preencher e reparar pequenas lacunas e peças danificadas de fornos..

Usado para a camada de isolamento do forno.

Na área externa do forno de pirólise, tijolos de isolamento são usados para reduzir a condução e perda de calor.

Revestimento de barreira térmica:

As superfícies externas do forno de pirólise são revestidas com um revestimento de barreira térmica. Esses revestimentos são geralmente feitos de fibras cerâmicas, cimento refratário e outros materiais, que pode fornecer melhor efeito de isolamento térmico.

Manta de fibra cerâmica

| Temperatura de classificação ℃ | 1140 | 1260 | 1400 | ||

| Nota | XT114 | XT126-A | XT126-B | XT140-A | XT140-B |

| Mudança linear permanente % ℃×24h | ≤-3 950 | ≤-3 1000 | ≤-3 1100 | ≤-3 1200 | ≤-3 1350 |

| Condutividade Térmica C/(m·K)500℃ | ≤0,153 | ||||

| Resistência à tração MPa 25 mm de espessura | >0,04 | >0,05 | >0,04 | >0,06 | |

| Densidade a granel kg/m3 | 64/96/128/160 | ||||

| al2O3 % | ≥44 | ≥45 | ≥45 | ≥52 | ≥36 |

| SiO2 % | ≥52 | ≥52 | ≥54 | ≥46 | ≥48 |

| ZrO2 % | / | / | / | / | ≥15 |

| Fé2O3 % | ≤1,0 | ≤0,8 | ≤0,2 | ≤0,2 | ≤0,1 |

| al2O3+SiO2 % | ≥96 | ≥97 | ≥99 | ≥99 | ≥ |

| al2O3+SiO2+ZrO2 % | / | / | / | / | 99 |

| Tamanho | 3600/7200×610 ×20/30/50 | ||||

Plástico refratário

| Item | Carboneto de silício | Zircônio Cromo Corindo | ||

| NMK4 | NMK5 | NMK6 | NMK7 | |

| Al2O3 % | / | / | / | ≥80 |

| SiC % | ≥40 | ≥60 | ≥70 | / |

| Cr2O3 % | / | / | / | ≥3 |

| ZrO2 % | / | / | / | ≥2 |

| Densidade aparente g/cm3 110℃×24h | ≥2,4 | ≥2,5 | ≥2,6 | ≥2,8 |

| Mudança Linear Permanente % 1000℃×3h | -0.4~0 | -0.5~0 | -0.6~0 | -0.6~0 |

| Resistência ao esmagamento a frio MPa 1000℃×3h | ≥60 | ≥70 | ≥80 | ≥90 |

| Resistência ao desgaste à temperatura ambiente cm3 1000℃×3h | ≤7 | ≤6 | ≤5 | ≤5 |

| Ciclo de estabilidade de choque térmico 1000 ℃ resfriamento a água | ≥30 | ≥35 | ≥40 | ≥30 |

| Índice de Plasticidade % | 15~55 | |||

| Plasticidade c/(m·K) 1000℃ | 3~5 | 5~7 | 6~8 | 2~3 |

| Temperatura máxima de serviço ℃ | 1400 | 1500 | 1600 | 1600 |

Castable refratário de alta alumina

| Índice | Fundível de alta alumina | |

| Al2o3% | 65 | |

| Sio2% | 30 | |

| Cao% | 6 | |

| Densidade aparente g/cm³ | 110℃,24h | 2.5 |

| 1350℃,24h | 2.6 | |

| Resistência à flexão a frio MPA | 110℃,24h | 6 |

| 1350℃,24h | 7.5 | |

| Resistência à flexão a quente MPA | 110℃,24h | 45 |

| 1350℃,24h | 60 | |

| 1350 Taxa de mudança da linha ardente | 0.2 | |

| Consumo de água de mistura % | 10-12% | |

| Temperatura de operação | 1400 | |

Fábrica de Refratários Rongsheng

Fábrica de Refratários Rongsheng

WeChat

Escaneie o código QR com o wechat