The main raw materials of the ladle slide gate are aluminum carbon and aluminum zirconium carbon. The need for special steel makes the development of ladle slide gates diversified. Sliding plate brick has the advantages of high fire resistance, good chemical stability, slag and liquid metal corrosion resistance, good oxidation resistance, and spalling resistance.

Ladle slide gate physical and chemical indicators

Physical and chemical indicators:

| Item | Index | |||

| HBLT80 | HBLT75 | HBLT70 | ||

| Al2O3 % | ≥80 | ≥75 | ≥70 | |

| C % | ≥2 | ≥3 | ≥3 | |

| Cold Crushing Strength MPa | Non impregnation | ≥80 | ≥70 | ≥60 |

| Impregnation | ≥100 | ≥90 | ≥80 | |

| Apparent porosity % | Nonimpregnation | ≤13 | ≤13 | ≤13 |

| Impregnation | ≤10 | ≤10 | ≤10 | |

| Bulk density g/cm3 | Nonimpregnation | ≥2.9 | ≥2.85 | ≥2.75 |

| Impregnation | ≥2.95 | ≥2.9 | ≥2.85 | |

Aluminum Zirconium Carbon:

| Item | Index | ||||

| HBLTG80 | HBLTG75 | HBLTG70 | HBMLT80 | ||

| Al2O3 % | ≥80 | ≥75 | ≥70 | / | |

| Al2O3+MgO % | / | / | / | ≥80 | |

| C % | ≥3 | ≥3 | ≥4 | ≥3 | |

| ZrO2 % | ≥4 | ≥4 | ≥4 | / | |

| Apparent porosity % | Nonimpregnation | ≤13 | ≤13 | ≤13 | ≤13 |

| Impregnation | ≤10 | ≤10 | ≤10 | ≤10 | |

| Bulk density g/cm3 | Non impregnation | ≥3.0 | ≥2.95 | ≥2.9 | ≥2.75 |

| Impregnation | ≥3.05 | ≥3.0 | ≥2.95 | ≥2.8 | |

| Cold Crushing Strength MPa | Non-impregnation | ≥90 | ≥90 | ≥80 | ≥70 |

| Impregnation | ≥110 | ≥110 | ≥100 | ≥90 | |

The function of the ladle slide gate

The ladle slide is an essential component in the steelmaking process. It is used to control the flow of molten steel from the ladle to the tundish during continuous casting. The slide is a refractory material designed to withstand high temperatures and mechanical stress.

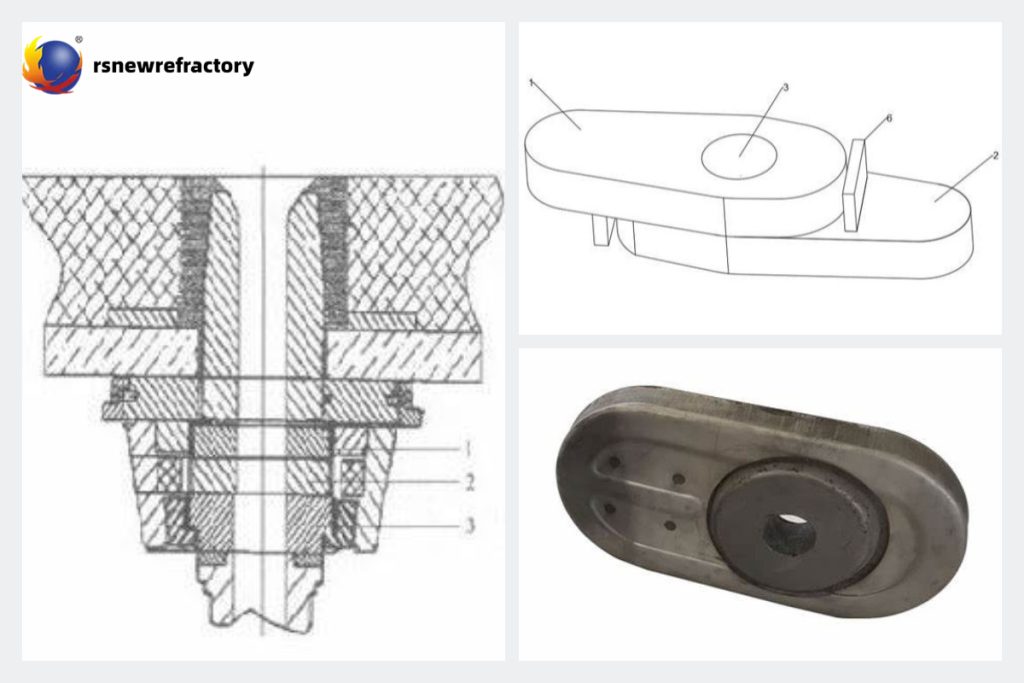

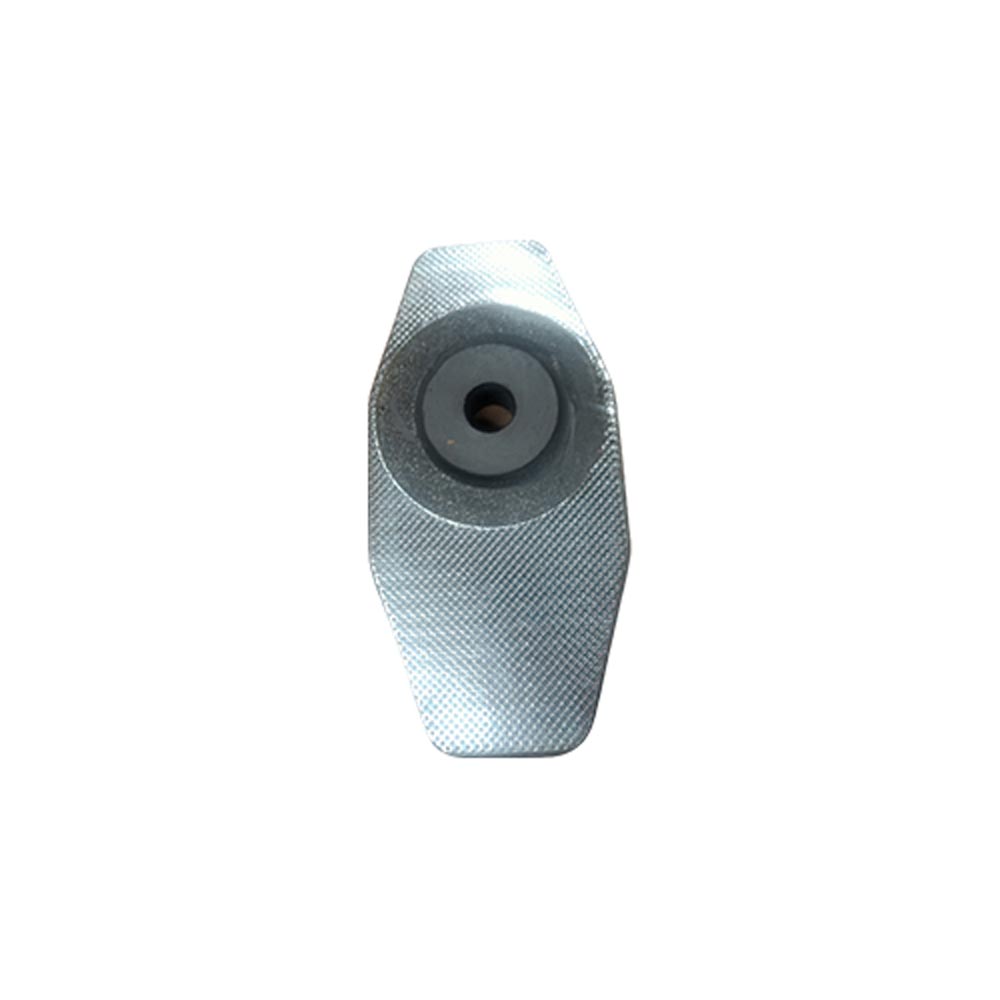

The ladle slide consists of upper and lower slides, a sliding mechanism and a shell. The upper and lower slides are made of high-quality refractory materials such as alumina or magnesium oxide and are designed to fit tightly to form a seal. The sliding mechanism is responsible for opening and closing the gate to allow the molten steel to flow through the ladle.

A sliding system operates the slide to allow the molten steel to flow through the ladle into the tundish. The gate is closed by a reversing process, pushing the upper plate back down onto the lower plate to form a tight seal. The ladle slide can accurately control the molten steel flow, thereby improving mold filling accuracy and improving the overall quality of the molten steel produced, thereby improving the efficiency of the steelmaking process and reducing overall production costs. The ladle slide helps prevent accidents and injuries that may occur during the molten steel delivery process.

Several common materials for slide gate

The following are the common materials for ladle slides: high aluminum slides, aluminum carbon slides, aluminum zirconium carbon slides, magnesium carbon and spinel carbon slides, and zirconia ladle slides.

Rongsheng company introduction

Rongsheng Company is a professional supplier of refractory materials, with 10 years of export experience, exporting to more than 80 countries. The main products of Rongsheng Company include various refractory bricks, unshaped refractory materials, metallurgical materials, thermal insulation materials, and so on.

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Scan the QR Code with wechat