Refractory mortar is made into new types of inorganic binder materials by choosing the same powder materials and adding inorganic binder, according to the request of construction materials. There are four grades below NT-1300, NT-1400, NT-1500, and NT-1600, each material is divided into lightweight and heavyweight, and we can choose relevant refractory mortar according to different requests for construction materials.

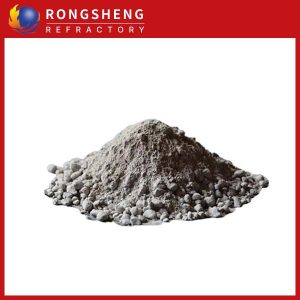

Refractory mortar parameters

MgO(%) | Al2O3(%) | Cr2O3(%) | Modules of rupture(MPa) | Refractoriness | Bonding Time | Bonder | ||

| ≥ | ≥ | 110℃ *24h | 1400℃ *3h | (℃) ≥ | (min) | |||

| Magnesia-chrome mortar | 78-85 | – | 3-5 | – | 2 | 1800 | 1-3 | Water glass |

| Magnesia-chrome composite mortar | 90 | – | 1-3 | – | 4 | 1800 | 1-3 | Water glass |

| Magnesia mortar | 85-90 | – | – | – | 3 | 1800 | 1-3 | Water glass |

| Spinel mortar | 80-85 | 4-8 | – | – | 4 | 1800 | 1-3 | Water glass |

| High alumina mortar | – | 60-75 | – | 1 | 4 | 1790 | 1-3 | Water |

| Anti-stripping high alumina mortar | – | 75 | – | 1 | 5 | 1790 | 1-3 | Water |

| Phosphate mortar | – | 70 | – | 1 | 5 | 1790 | 1-3 | Phosphate |

| P901 mortar | – | 75 | – | 1.5 | 6 | 1790 | 1-3 | Phosphate |

| Alkai-resistant mortar | – | 30-35 | – | 1 | 3 | 1690 | 1-3 | Water |

| Insulating alkali-resistant mortar | – | 30-40 | – | 1 | 1.5 | 1650 | 1-3 | Water |

| Silicon mud (RSGN-96) | Sio2%≥96 | 0.6 | – | 0.5 | 1.5 | 1710 | 1-3 | Water |

| Silicon mud (RSGN-94) | Sio2%≥94 | – | – | 1 | 3 | 1690 | 1-3 | Water |

| Silicon heat insulation mud(RSGGN-94) | Sio2%≥94 | – | – | 0.5 | 1.5 | 1690 | 1-3 | Water |

| Silicon heat insulation mud(RSGGN-92) | Sio2%≥92 | – | – | 0.5 | 1.5 | 1670 | 1-3 | Water |

| Wear-resisting refractory mortar | – | – | – | – | 1000℃*3h(4-6) | 1790 | 1-3 | Water |

| Light refractory mortar | – | – | – | – | – | 1650 | 1-3 | Water |

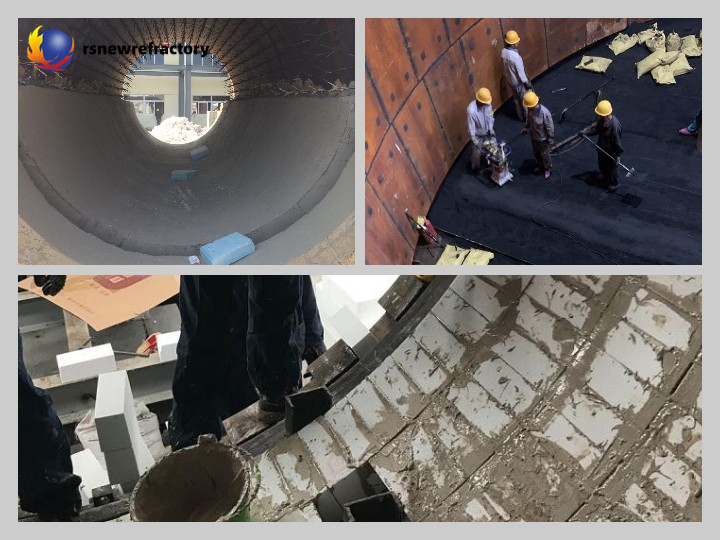

Application of refractory mortar

Application industries include metallurgy, building materials, machinery, petrochemicals, glass, boilers, electric power, steel, cement, etc. The material of refractory mortar shall be consistent with that of masonry refractory products. In addition to being used as a pointing material, refractory mud can also be used as a protective layer for linings by coating or spraying.

Characteristics of high-heat mortar

Safety: The mortar does not produce sparks when impacted or rubbed, and is particularly suitable for environments with flammable and explosive substances.

Wear-resistant: It has excellent wear resistance, can effectively resist various wear and tear, and extends the service life of the floor.

Anti-slip: Its surface is smooth and has good anti-slip properties, which can effectively reduce accidents.

Anti-static: The mortar has good conductive properties, which can effectively prevent static electricity accumulation and avoid potential dangers.

Convenient construction: It can be directly added with water and stirred in proportion, and the construction operation is simple and convenient.

Environmental protection: The mortar does not contain chemicals harmful to the human body and the environment, and meets environmental protection requirements.

Construction process of refractory mortar

- Basic cleaning. First of all, it is necessary to clean the surface of the foundation to avoid debris such as floating dust and oil.

- Wet construction surface. Before application, use a roller or sprinkler to wet the surface, but there should be no excess water during application.

- Configure materials. Mix mortar and water, and add water at 14-20%, depending on the actual situation.

- Smooth the surface. The stirred mortar is poured on the operation plane, which needs to be completed within 20 minutes.

- Maintenance. Sprinkle water after repair, or cover with plastic film for maintenance.

Why choose Rongsheng monolithic refractory company

Newly upgraded fully automatic production line

Rongsheng has a newly upgraded fully automatic production line, which can realize the automatic production of amorphous products such as refractory cement, refractory castables, refractory mortar, etc., and realize high-quality and efficient production of refractory materials.

Professional Engineer Service

We have a team of experienced engineers who can provide customers with professional refractory solutions to ensure the best use of the products.

Strong refractory factory supply capacity

Rongsheng Refractory has two refractory factories. Rongsheng is able to supply a large number of monomer refractory products stably. More importantly, it has exported refractory materials to more than 50 countries and has rich export experience.

High-quality refractory products

Rongsheng will strictly control product quality, which provides customers with high-quality product assurance. At the same time, we can customize refractory materials for customers.

Rongsheng Refractories Factory

Rongsheng Refractories Factory

FOR 50 KILOS BAG OF REFRACTARY CASTLE HOW MANY LITROS OF WATER DO WE NEED+584121968090

ok,we will contact you as soon as possible