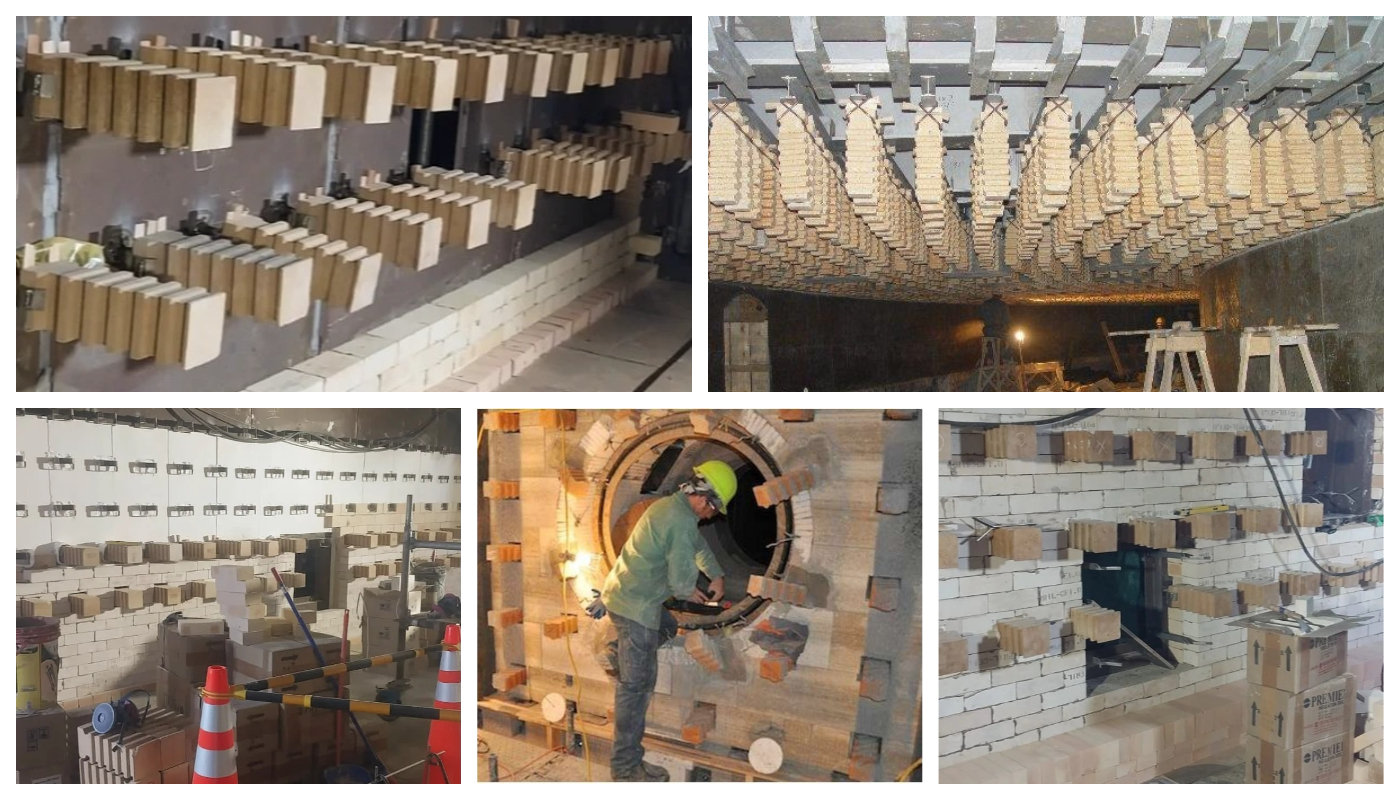

Refractory anchor brick is a type of material with a specific shape, used for internal fixation and support of industrial furnaces and other equipment. It is made of high-quality refractory raw materials through molding, sintering, and other processes, and has excellent refractory resistance and mechanical strength.

The function of anchor bricks

Anchor bricks, also known as hanging bricks and anchors, are a new type of anchor bricks for industrial furnaces. The electric furnace top is a furnace roof structure supported between metal hanging bricks and refractory bricks. Therefore, the leakage of reactive gases and hot gases in the furnace will damage the metal hanging parts, causing the furnace roof to collapse. Industrial kiln and flue walls are composed of inner lining, insulation layer, and outer wall layer. The inner lining is refractory bricks and the outer wall is made of ordinary fired bricks. These layers need to be connected and anchored. The tensile and flexural strength of the anchor is significantly improved. The stress generated at the groove is blocked at the ribs and cannot be transmitted further, so the anchor bricks of this structure are not easy to break.

Physical and chemical indicators of high alumina anchor bricks

| Project | index | |||

| LZ-55A | LZ-55B | LM-75A | LM-75B | |

| AI2O3 %≥ | 55.0 | 75.0 | ||

| CaO %≤ | 2.0 | 2.0 | ||

| Normal temperature compressive strength MPa≥ | 50 | 55 | ||

| Load softening starting temperature℃ ≥ | 1450 | 1550 | ||

| Apparent porosity %≤ | 22 | 24 | 21 | 23 |

| Bulk density g/cm3 | 2.30 | 2.60 | ||

Precautions for laying anchor bricks

- When laying bricks, apply mud carefully from both sides to prevent gas from leaking from the top of the furnace.

- The hanging part of the anchor brick should not be damaged (it should play the role of hanging metal parts)

- Ensure the size of the joints, carry out top construction, and correctly determine the role of hanging metal parts.

- Appropriate expansion joints should be left between the furnace body and anchor bricks

- Generally use air-hardening mud.

Refractory anchor brick application

Refractory anchor bricks are mainly used for lining blast furnaces, hot blast furnaces, electric furnace tops, blast furnaces, reverberatory furnaces, and rotary kilns. In addition, high alumina bricks are also widely used as open-hearth regenerative checker bricks, plugs for pouring systems, nozzle stones, etc.

Factory delivery

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Scan the QR Code with wechat