Ceramic foam is a type of porous ceramic material that is made by adding a foaming agent to a ceramic slurry and then firing it at high temperatures. The resulting material has a three-dimensional network of interconnected pores, which gives it unique properties such as high thermal and chemical resistance, excellent filtration capabilities, and high mechanical strength.

Foam ceramics details

| Brand | Bulk Density,g/cm3 | Porosity % | Cold Crush StrengthMPa | Thermal shock stability 1100℃ cycle | High Temperature Bending strength1200℃ MPa |

| PTW-G | 0.4~0.85 | ≥76 | ≥1.2 | ≥2 | ≥0.6 |

| PTW-T | 0.36~0.5 | ≥80 | ≥1.0 | ≥2 | ≥0.6 |

| PTW-L | 0.3~0.5 | ≥80 | ≥0.8 | ≥2 | ≥0.4 |

| Specification: customized size; Hole density 0~50PPI | |||||

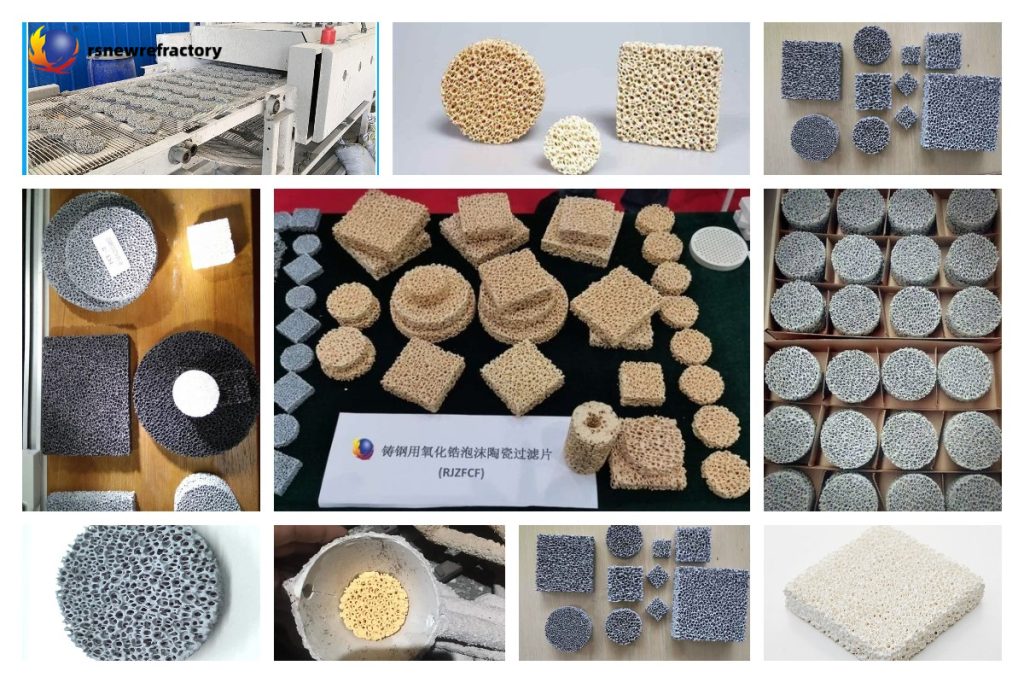

Ceramic foam filter material

The basic materials of foam ceramic filters are silicon carbide, zirconium oxide, and aluminum oxide.

Applications of foam ceramics

- Catalyst carrier material

Foam ceramics have high specific surface properties. As a catalyst carrier, they can increase the effective contact area and enhance the catalytic effect. Because of their advantages such as heat resistance, non-pollution, not being easily poisoned, and low cost, they have been widely used in automobile exhaust, chemical industry, and other fields to treat toxic and toxic substances: foul smell and other harmful gases. - Insulating materials

The closed pores in foam ceramics reduce heat release efficiency and reduce convection in heat propagation. They have excellent properties such as low thermal conductivity and thermal shock resistance, and are excellent heat-resistant materials. - Burner

As a porous medium burner, foam ceramic material can reduce the flame temperature through the good heat exchange rate of the ceramic material, and perform premixed combustion of various fuels in or near the surface of the inert porous ceramic, saving energy and significantly reducing COX and NOX. emission. - Sound-absorbing materials

Foam ceramics have a large number of pores with a three-dimensional network structure. The incoming sound waves cause the air in the pores to vibrate and cause friction in the ceramic tendons. The viscosity effect causes the sound waves to be converted into heat and disappear, achieving the effect of absorbing sound. - Biological materials

Porous hydroxyapatite ceramics are very similar to the inorganic components of human bones and teeth. They are non-toxic to the human body and have high biocompatibility and biological activity. Their interconnected pores are conducive to the microcirculation of tissue fluid and promote the infiltration of cells. and growth.

Preparation technology of ceramic foam filter

The main processes for preparing foam ceramics include the organic (polymer) foam infiltration process, foaming process, pore-forming agent addition process, sol-gel process, and gel injection molding process.

Rongsheng company introduction

Rongsheng Company is a professional supplier of refractory materials, with 10 years of export experience, exporting to more than 80 countries. The main products of Rongsheng Company include various refractory bricks, unshaped refractory materials, metallurgical materials, thermal insulation materials, and so on.

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Scan the QR Code with wechat