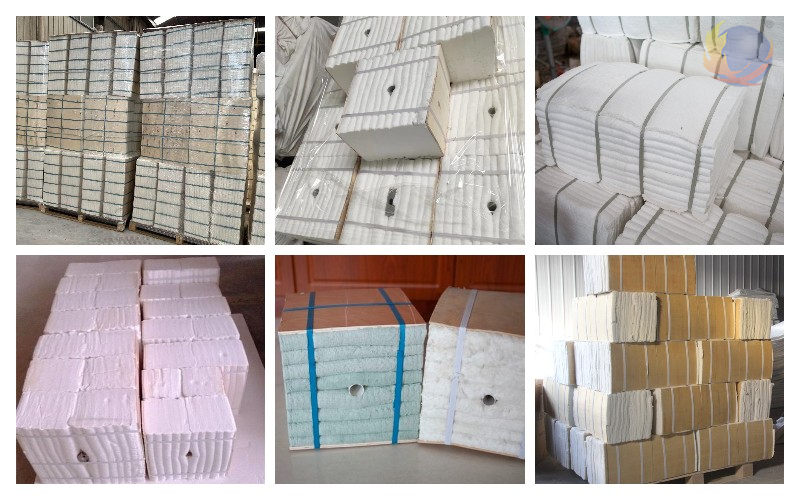

The ceramic fiber module is also called an aluminum silicate fiber module; ceramic fiber modules are a type of insulation material used in various high-temperature applications, such as furnaces, and kilns. They are made of ceramic fibers, which are processed into a blanket form and then folded and compressed to form modules. In this article, we will take a closer look at ceramic fiber modules, including 1260C ceramic fiber modules, aluminum silicate ceramic fiber modules, and insulating ceramic fiber modules.

Ceramic fiber module technical indicators

| Classification Temperature | 1260 | 1400 | |||

| Products Code | RSNC-289 | RSNC-389 | RSNC-489 | RSNC-589 | |

| Heating Permanent Linear Change (%) | 1000℃*24h≤-3 | 1100℃*24h≤-3 | 1200℃*24h≤-3 | 1350℃*24h≤-3 | |

| Theoretical Thermal Conductivity(W/m*k) | Average 200℃ | 0.045-0.060 | |||

| Average 400℃ | 0.095-0.120 | ||||

| Average 600℃ | 0.160-0.195 | ||||

| Theoretical Bulk Density (kg/m3) | 200±10, 220±10 | ||||

| Products Specification | 300*300*200/250 | ||||

| Al2O3 (%) | ≥45 | ≥45 | 52~55 | – | |

| ZrO2 (%) | – | – | – | 15~17 | |

| Al2O3 + SiO2 (%) | ≥97 | ≥99 | ≥99 | – | |

| Al2O3+SiO2+ZrO2 (%) | – | – | – | ≥99 | |

| Fe2O3 (%) | ≤1.0 | ≤0.2 | ≤0.2 | ≤0.2 | |

| K2O+Na2O (%) | ≤0.5 | ≤0.2 | ≤0.2 | ≤0.2 | |

Features of ceramic fiber modules

Ceramic fiber modules have excellent chemical stability, excellent thermal stability, and excellent elasticity. Ceramic fiber modules are in a pre-pressed state. After the furnace lining is built, the expansion of the ceramic fiber modules makes the furnace lining seamless and can compensate for the shrinkage of the fiber lining to improve the thermal insulation performance of the fiber lining. The overall performance is good; excellent thermal stability and thermal shock resistance: Insulation modules are installed quickly, and the anchors are set on the cold surface of the wall lining, which can reduce the requirements for the anchor material.

Application of aluminum silicate fiber module

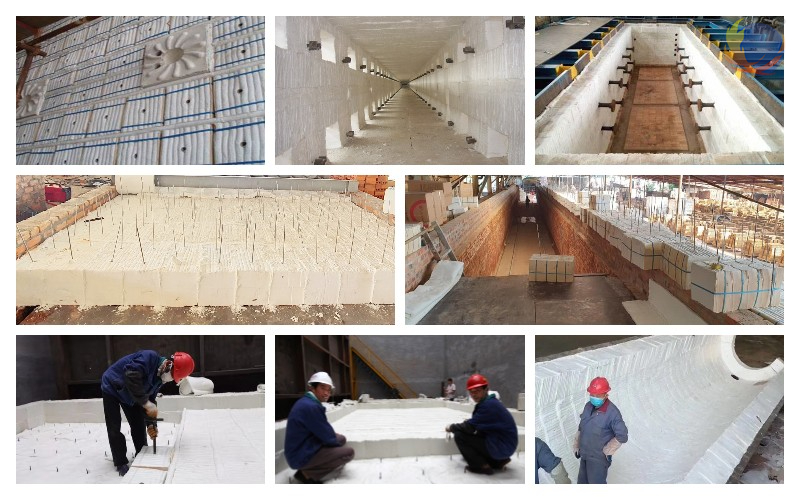

Aluminum silicate fiber module is used for lining insulation of kilns in the petrochemical industry; lining insulation of kilns in the metallurgical industry; lining insulation of kilns in ceramic, glass, and other building materials industries; lining insulation of heat treatment furnaces in the heat treatment industry; lining insulation of other industrial kilns. With the advancement of the national energy conservation and emission reduction plan, the transformation of fired brick tunnel kilns is imminent. Ceramic fiber modules have been highly praised for their excellent thermal insulation performance in the ceiling of fired brick tunnel kilns.

Ceramic fiber module installation

Installation method

Derust the furnace plate → weld the module bolts to the plate → remove the module → screw the module guide rod to the small head of the screw → pass the module through the guide rod along the center hole and lean it against the furnace plate → use a special wrench to tighten the nut to the screw → unscrew the guide rod → install other modules in turn → pull out the central plastic tube of the module → remove the module strapping belt → install the next row of folding modules

Installation requirements

· Anchor nails should be welded and placed accurately, and the error should be strictly controlled:

· Install the backing layer first, then install the fiber module:

· Install the furnace roof module first and then install the furnace wall:

· The furnace wall module should be installed from the bottom to the top:

· The “soldier row” arrangement mostly arranges the modules in the same direction. After installing a row of modules, the compensating blanket should be compressed and laid as required:

· The joints between the roof and the wall and between the walls should be compressed and laid with compensating blankets.

What types of ceramic fibers are there?

There are many types of ceramic fibers, such as ceramic fiber blankets, ceramic fiber boards, ceramic ropes, and ceramic fiber cloths. The sizes of ceramic fiber products can be customized. If you have any needs, please get in touch with us!

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Scan the QR Code with wechat