Typen en kenmerken van afvalverbrandingsovens

Afvalverbrandingsovens zijn een soort apparatuur voor de behandeling van vast afval. Het verbrandt het afval tot as en rook door hoge temperaturen, waardoor de hoeveelheid afval wordt verminderd en schadelijke stoffen worden afgevoerd. Hieronder volgen enkele veel voorkomende soorten afvalverbrandingsovens.

Vijf soorten afvalverbrandingsovens

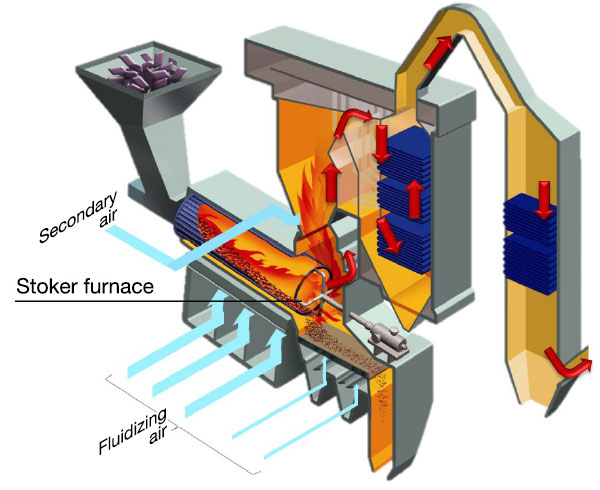

Roostertype verbrandingsoven

De roosteroven werkt continu en kan oververwerken 200 ton afval per dag. Hij is voorzien van een ovenrooster aan de onderkant, en afval wordt aangevoerd via de bovenste trechter. Het te verbranden afval wordt op het ovenrooster geplaatst, en verbrandingslucht wordt vanaf de bodem van de oven ingeblazen voor drogen en directe verbranding. Bij gebruik van een roosteroven voor afvalverwerking, het sorteren of vermalen van afval is over het algemeen niet nodig, behalve grote artikelen. De oppervlaktetemperatuur van de afvallaag kan oplopen tot 800°C, en het temperatuurbereik van het rookgas ligt tussen 2800 en 1000°C. De verbrandingsoven heeft slechts één verbrandingskamer, zorgen voor een betrouwbare verbranding, goede benutting van restwarmte, stabiele verbrandingsprestaties, en een hoog burn-outpercentage. Vast afval blijft ongeveer in de oven 1 naar 3 uur, terwijl gassen slechts een paar seconden blijven bestaan. Dit type verbrandingsoven is lang en slank, met een groot volume. Het vereist geavanceerde operationele technieken, brengt hogere kosten met zich mee, en het rooster moet bestand zijn tegen hoge temperaturen, en corrosie, en hebben goede mechanische eigenschappen, of het kan gevoelig zijn voor beschadiging.

CAO (Gecontroleerde luchtoxidatie) verbrandingssysteem

De CAO (Gecontroleerde luchtoxidatie) verbrandingsinstallatie is een nieuw type afvalverbrandingsinstallatie met een verwerkingscapaciteit van maximaal 150 ton per dag. De belangrijkste kenmerken zijn onder meer een proces in twee fasen: Eerst, het afval ondergaat thermische oxidatie-ontleding, gevolgd door vergassing en verbranding. Dit resulteert in een stabiele verbranding met een hoog uitbrandrendement. Echter, het verbrandingsproces is langzaam, en het vereist nauwkeurige controle van het zuurstofniveau en de oventemperaturen. Als het afval een hoog vochtgehalte heeft en geen olieondersteunde ontsteking heeft, Er kan mogelijk geen stabiele verbranding worden bereikt. Het systeem bestaat uit twee verbrandingskamers: vast afval blijft in de eerste kamer (bij temperaturen van 600-800°C) voor ongeveer 3-6 uur, terwijl gassen door de tweede kamer gaan (bij temperaturen van 800-1000°C) voor ongeveer 1-3 seconden, aangedreven door een propeller.

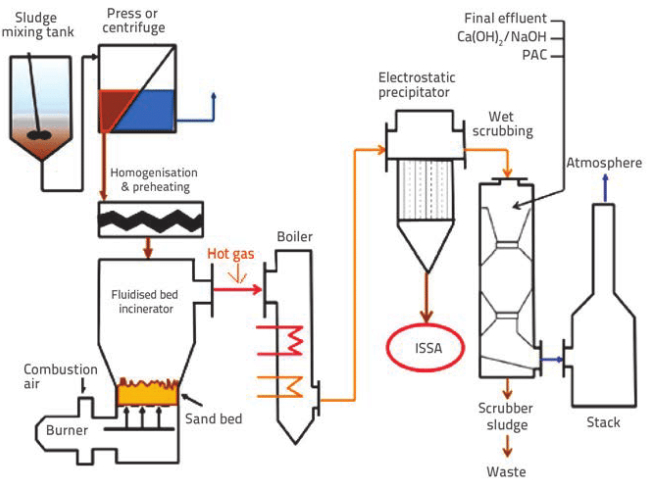

Wervelbedverbrandingsoven

De wervelbedoven is opgebouwd uit poreuze verdeelplaten. Er wordt een grote hoeveelheid kwartszand aan de oven toegevoegd, verwarmd tot meer dan 600°C, en hete lucht (boven 200°C) wordt van onderaf geblazen, waardoor het zand gaat koken. Dan, het afval wordt geïntroduceerd. Het afval kookt samen met het hete zand, snel uitdrogen, ontstoken, en verbrand. Voordat u de oven ingaat, het afval moet worden gesorteerd en vermalen (10-30cm). Binnen in de oven, het ondergaat een hangende verbranding. Dit hoogefficiënte proces leidt tot een grondige verbranding. Echter, de afvalverwerkingscapaciteit van de verbrandingsoven is beperkt tot minder dan 150 ton per dag. De temperatuur in de oven is gelijkmatig, en de verbrandingssnelheid is relatief snel. Vast afval blijft in de oven 1-2 uur, terwijl gassen slechts enkele seconden in de oven blijven.

Roterende oven voor industrieel afval

De draaitrommeloven bestaat uit een draaitrommeloven, afvaltoevoerapparaat, secundaire verbrandingskamer, en brander, en is voorzien van een ovenrooster aan de achterzijde voor naverbranding. Dit type draaitrommeloven is geschikt voor de verwerking van grootschalig afval en bedrijfsafval (zoals slib, verfresten, kunststoffen, enz.) zonder dat het afval vooraf moet worden ingedeeld of vermalen. Het heeft een verwerkingscapaciteit van ruim 200 ton per dag. Vast afval blijft in de draaitrommeloven achter 2-4 uur bij een temperatuur van ongeveer 900°C. De temperatuur in de achterste verbrandingskamer ligt tussen de 1000-1200°C. De asdeeltjes die na verbranding ontstaan zijn klein, en de burn-outefficiëntie is relatief hoog.

Kenmerken van vier soorten afvalverbrandingsovens

Van bovenstaande vier soorten afvalverbrandingsovens, kan worden opgemerkt dat conventionele afvalverbrandingsinstallaties in het algemeen bij relatief lage verbrandingstemperaturen werken, typisch onder 1000°C. Als resultaat, sommige brandbare materialen ondergaan mogelijk geen volledige verbranding. Gevaarlijke afvalcomponenten, zoals die gevonden worden in medisch afval, worden niet grondig verwerkt, die een negatieve invloed kunnen hebben op de lokale bodem- en waterkwaliteit, wat leidt tot secundaire milieuvervuiling. Aanvullend, verbranding bij lage temperaturen kan dioxines genereren die schadelijk zijn voor zowel het natuurlijke milieu als de menselijke gezondheid. Om een uitgebreide verbranding te garanderen en een nuluitstoot van dioxines te bereiken, Sinds de jaren tachtig zijn er bij de behandeling van vast afval veel geavanceerde technologieën toegepast. Deze omvatten ultrasone methoden, vergassing-smelttechnieken, benaderingen van uit afval afkomstige brandstoffen, en fotochemische oxidatietechnologieën.

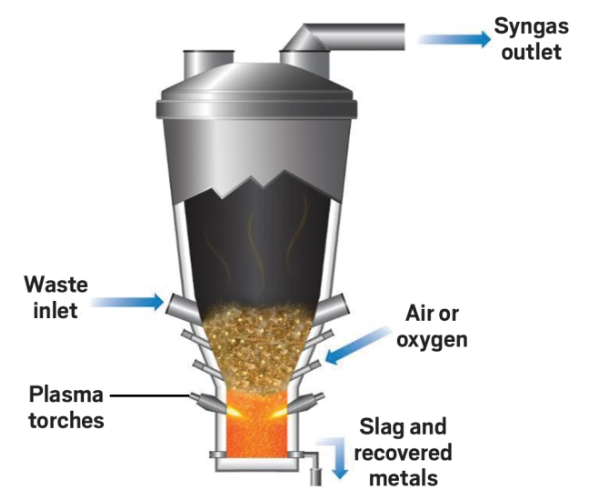

Plasmavergasser

Vergeleken met traditionele verbrandingstechnieken, plasmatechnologie ioniseert de lucht, binnen een fractie van een seconde worden temperaturen van 3000°C tot 10.000°C bereikt. Deze hoge temperatuur zorgt ervoor dat giftige stoffen snel worden afgebroken, het voorkomen van de vorming van dioxines. Gevaarlijke gassen en zware metalen worden na behandeling in de plasmaoven onschadelijk gemaakt. Wanneer afval in de plasmavergassingsoven wordt gevoerd, organisch afval ondergaat een snelle uitdroging, pyrolyse, en ontbinding, waarbij een mengsel van brandbare gassen ontstaat dat hoofdzakelijk uit H2 bestaat, CO, en sommige organische gassen. Dit wordt verder onderworpen aan secundaire verbranding om reductie en onschadelijkheid te bereiken. Anorganische materialen (zoals metalen, glas, enz.) smelten onder het hoge temperatuur plasma, reductie realiseren. Vergeleken met traditionele verbranding, plasmatechnologie zorgt voor een grondigere behandeling van gevaarlijk afval, waarbij een kristallijn residu ontstaat dat geen gevaar oplevert en kan worden gebruikt in bouwmaterialen zonder dat het hoeft te worden begraven. Via dit proces, Het afvalvolume wordt aanzienlijk verminderd, giftige stoffen worden afgebroken, en verbrandingsas vormt glasslakken, transformeren in onschadelijk materiaal. Plasmatechnologie voor risicovol afval is de trend in de verwerking van gevaarlijk afval.

Het werktemperatuurbereik van de plasmavergassingsoven bedraagt 1200°C tot 1700°C, waarbij temperaturen nabij de plasmatoorts oplopen tot 1700°C. Deze onmiddellijke hoge temperatuur stelt hoge eisen aan de weerstand van het vuurvaste materiaal tegen thermische spanning. Het proces omvat intense thermische straling, waardoor een snelle verwarming van het oppervlak van het vuurvaste materiaal ontstaat, resulterend in aanzienlijke temperatuurgradiënten en thermische stress. Aanvullend, Bij de vergassing van afval ontstaat een grote hoeveelheid waterdamp, welke, bij het stijgen, kan het vuurvaste materiaal in de bovenste bekleding van de oven ernstig aantasten.

Rongsheng Vuurvaste Fabriek

Rongsheng Vuurvaste Fabriek

WeChat

Scan de QR-code met wechat