Silica vuurstenen geëxporteerd naar Rusland

China Rongsheng Refractories Co., Ltd. is a professional enterprise engaged in the production and export of vuurvaste materialen. Our products are very popular in domestic and foreign markets. Onlangs, we exported high-quality silica fire bricks to Russia, providing Russian customers with high-quality refractory solutions.

Demand for Russian refractory materials

The Russian company needs a batch of high-performance silica fire bricks for the lining construction of the kiln. Silica refractory bricks need to have properties such as high-temperature resistance, slijtvastheid, and chemical stability to meet the continuous operation needs of the kiln in high-temperature environments. Rongsheng provides customized silica fire bricks product solutions. These silica fire bricks are carefully designed and manufactured to ensure their stability and durability in high temperatures and corrosive environments.

Payment methods for Russian customers

The customer chooses to pay in RMB, and the two parties agree on the stage and method of payment. According to the contract agreement, the customer paid a certain percentage of advance payment after the order was confirmed to ensure the start of production. Subsequently, the remaining payment was made before the shipment of the goods.

Shipping of silica bricks to Russia

Customers have two modes of transportation to choose from, sea and land. In view of the urgency and geographical location of the project, the customer finally chose land transportation. This mode of transportation can not only shorten the delivery time but also reduce the potential risk of ocean transportation.

Uses of silica refractory bricks

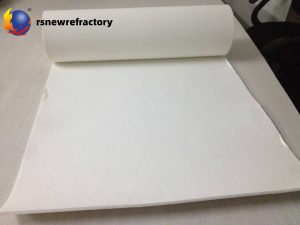

Silica refractory brick is mainly used to build the carbonization chamber, verbrandingskamer, and partition walls of coke ovens, glass tank kilns, kiln roofs, tank walls, high-temperature load-bearing parts of hot blast furnaces, koolstofbrandovens, and other thermal kilns. In order to improve the production capacity of modern large coke ovens, it is necessary to thin the coke oven carbonization chamber, verbrandingskamer, and partition walls, thus requiring the use of highly dense and high thermal conductivity silica refractory bricks. There are many varieties of silica refractory bricks. According to their uses, they are divided into silica refractory bricks for coke ovens, silica fire bricks for hot blast furnaces, silica refractory bricks for electric furnaces, silica refractory bricks for glass kilns, enz. According to the complexity of the brick type, it is divided into standard bricks, common bricks, special-shaped bricks, and special-shaped bricks.

Rongsheng Vuurvaste Fabriek

Rongsheng Vuurvaste Fabriek

WeChat

Scan de QR-code met wechat