Van vuurvaste mortel worden nieuwe soorten anorganische bindmiddelen gemaakt door dezelfde poedermaterialen te kiezen en anorganische bindmiddelen toe te voegen, volgens het verzoek van bouwmaterialen. Er zijn vier kwaliteiten onder NT-1300, NT-1400, NT-1500, en NT-1600, elk materiaal is verdeeld in lichtgewicht en zwaargewicht, en we kunnen relevante vuurvaste mortel kiezen op basis van verschillende verzoeken voor bouwmaterialen.

Vuurvaste mortelparameters

MgO(%) | Al2O3(%) | Cr2O3(%) | Modules van breuk(MPa) | Vuurvastheid | Bondingstijd | Boeren | ||

| ≥ | ≥ | 110℃ *24 uur | 1400℃ *3 uur | (℃) ≥ | (min) | |||

| Magnesia-chroommortel | 78-85 | – | 3-5 | – | 2 | 1800 | 1-3 | Waterglas |

| Magnesia-chroom composietmortel | 90 | – | 1-3 | – | 4 | 1800 | 1-3 | Waterglas |

| Magnesia-mortel | 85-90 | – | – | – | 3 | 1800 | 1-3 | Waterglas |

| Spinel-mortel | 80-85 | 4-8 | – | – | 4 | 1800 | 1-3 | Waterglas |

| Hoge aluminiumoxide mortel | – | 60-75 | – | 1 | 4 | 1790 | 1-3 | Water |

| Anti-strippende mortel met hoog aluminiumoxidegehalte | – | 75 | – | 1 | 5 | 1790 | 1-3 | Water |

| fosfaat mortel | – | 70 | – | 1 | 5 | 1790 | 1-3 | Fosfaat |

| P901 mortel | – | 75 | – | 1.5 | 6 | 1790 | 1-3 | Fosfaat |

| Alkai-bestendige mortel | – | 30-35 | – | 1 | 3 | 1690 | 1-3 | Water |

| Isolerende alkalibestendige mortel | – | 30-40 | – | 1 | 1.5 | 1650 | 1-3 | Water |

| Silicium modder(RSGN-96) | Sio2%≥96 | 0.6 | – | 0.5 | 1.5 | 1710 | 1-3 | Water |

| Silicium modder(RSGN-94) | Sio2%≥94 | – | – | 1 | 3 | 1690 | 1-3 | Water |

| Silicium warmte-isolatie modder(RSGGN-94) | Sio2%≥94 | – | – | 0.5 | 1.5 | 1690 | 1-3 | Water |

| Silicium warmte-isolatie modder(RSGGN-92) | Sio2%≥92 | – | – | 0.5 | 1.5 | 1670 | 1-3 | Water |

| Slijtvaste vuurvaste mortel | – | – | – | – | 1000℃*3 uur(4-6) | 1790 | 1-3 | Water |

| Licht vuurvaste mortel | – | – | – | – | – | 1650 | 1-3 | Water |

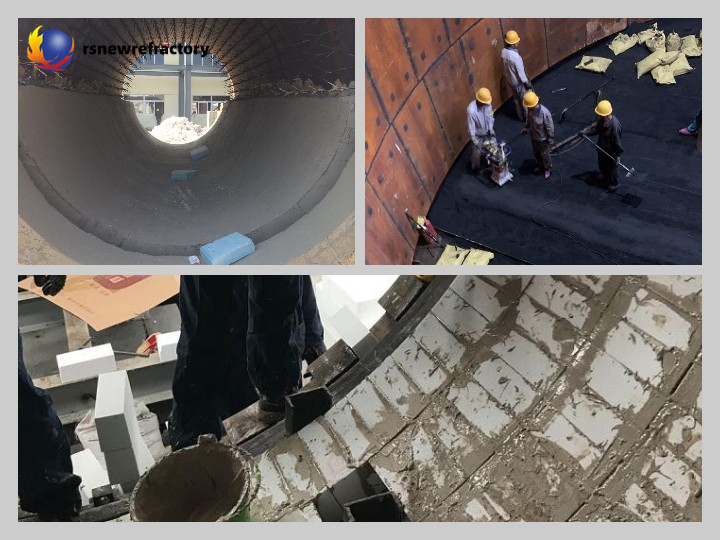

Aanbrengen van vuurvaste mortel

Toepassingsindustrieën omvatten de metallurgie, bouwmaterialen, machines, petrochemie, glas, ketels, elektrische energie, staal, cement, enz. Het materiaal van vuurvaste mortel moet overeenkomen met dat van vuurvaste metselwerkproducten. Daarnaast wordt het gebruikt als aanwijsmateriaal, Vuurvaste modder kan ook worden gebruikt als beschermende laag voor bekledingen door middel van coating of spuiten.

Kenmerken van mortel voor hoge temperaturen

Veiligheid: De mortel veroorzaakt geen vonken bij stoten of wrijven, en is bijzonder geschikt voor omgevingen met brandbare en explosieve stoffen.

Slijtvast: Het heeft een uitstekende slijtvastheid, kan effectief verschillende slijtage weerstaan, en verlengt de levensduur van de vloer.

Antislip: Het oppervlak is glad en heeft goede antislipeigenschappen, waardoor ongevallen effectief kunnen worden verminderd.

Antistatisch: De mortel heeft goede geleidende eigenschappen, die de accumulatie van statische elektriciteit effectief kan voorkomen en potentiële gevaren kan vermijden.

Handige constructie: Het kan direct met water worden toegevoegd en in verhouding worden geroerd, en de bouwoperatie is eenvoudig en handig.

Milieubescherming: De mortel bevat geen chemicaliën die schadelijk zijn voor het menselijk lichaam en het milieu, en voldoet aan de eisen op het gebied van milieubescherming.

Bouwproces van vuurvaste mortel

- Basis schoonmaak. Allereerst, het is noodzakelijk om het oppervlak van de fundering schoon te maken om vuil zoals drijvend stof en olie te voorkomen.

- Nat bouwoppervlak. Voor toepassing, gebruik een roller of sproeier om het oppervlak nat te maken, maar er mag tijdens het aanbrengen geen overtollig water zijn.

- Materialen configureren. Meng mortel en water, en voeg water toe 14-20%, afhankelijk van de feitelijke situatie.

- Maak het oppervlak glad. De geroerde mortel wordt op het bedieningsvlak gegoten, die binnen moet worden voltooid 20 minuten.

- Onderhoud. Na reparatie water sprenkelen, of afdekken met plasticfolie voor onderhoud.

Waarom kiezen voor het monolithische vuurvaste bedrijf Rongsheng

Nieuw geüpgradede volautomatische productielijn

Rongsheng heeft een onlangs geüpgradede, volautomatische productielijn, die de automatische productie van amorfe producten zoals kan realiseren vuurvast cement, vuurvaste gietstukken, vuurvaste mortel, enz., en het realiseren van een hoogwaardige en efficiënte productie van vuurvaste materialen.

Professionele ingenieursdienst

We hebben een team van ervaren ingenieurs die klanten professionele vuurvaste oplossingen kunnen bieden om het beste gebruik van de producten te garanderen.

Sterke vuurvaste fabrieksleveringscapaciteit

Rongsheng Refractory heeft twee vuurvaste fabrieken. Rongsheng kan een groot aantal monomeer vuurvaste producten stabiel leveren. Nog belangrijker, het heeft vuurvaste materialen naar meer dan geëxporteerd 50 landen en heeft een rijke exportervaring.

Hoogwaardige vuurvaste producten

Rongsheng zal de productkwaliteit strikt controleren, die klanten hoogwaardige productgarantie biedt. Tegelijkertijd, we kunnen vuurvaste materialen voor klanten aanpassen.

Rongsheng Vuurvaste Fabriek

Rongsheng Vuurvaste Fabriek

VOOR 50 KILO ZAK VUURKASTEEL HOEVEEL LITROS WATER HEBBEN WE NODIG+584121968090

OK,we nemen zo snel mogelijk contact met u op