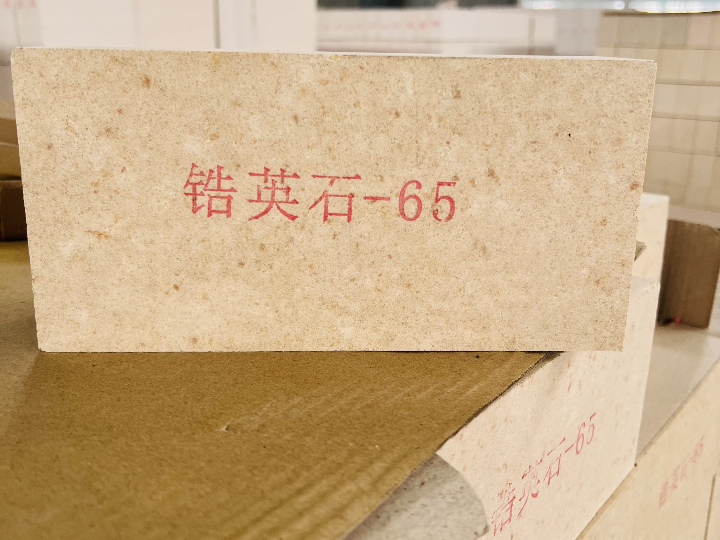

Zircon brick is a refractory product made of zircon as raw material and soft clay as a binder.

Zircon brick production process

After the zircon sand is pulverized, it is made into agglomerates, and after being calcined, it is pulverized into a suitable particle size. After batching → mixing → trapping → high-pressure molding → drying → high-temperature firing.

Physical and chemical indicators of zircon bricks

| Item | Inhoudsopgave |

| ZrO2 % | ≥65 |

| SiO2 % | ≤33 |

| Fe2O3 % | ≤0,2 |

| TiO2 % | ≤1,2 |

| Bulkdichtheid g/cm3 | ≥3.8 |

| Schijnbare Porositeit % | ≤17 |

| Koude breeksterkte MPa | ≥120 |

| 0.2Mpa Vuurvastheid onder belasting ℃ | ≥1700 |

| Thermische schokbestendigheidscyclus 1100 ℃ waterkoeling | >10 |

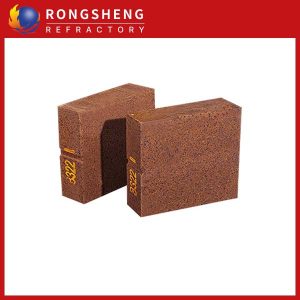

Product features of zircon bricks

- Weerstand tegen hoge temperaturen, Grote sterkte

- Strong anti-strike ability, anti-washing, and erosion of molten steel and glass solution

- Lage thermische uitzettingssnelheid, stable volume at high temperature

- Goede thermische schokbestendigheid

- High bulk density, lage porositeit, and strong permeability resistance

Application of zircon brick

- Masonry steel drum lining for degassing, stainless steel drum lining, continuous casting steel drum lining, sprue brick, plug brick, and high-temperature induction furnace lining.

- For parts that contact glass solution.

- Zircon bricks have the property of not being corroded by metal chromium, aluminum oxides, and their slag. Can be used in the bottom of a furnace.

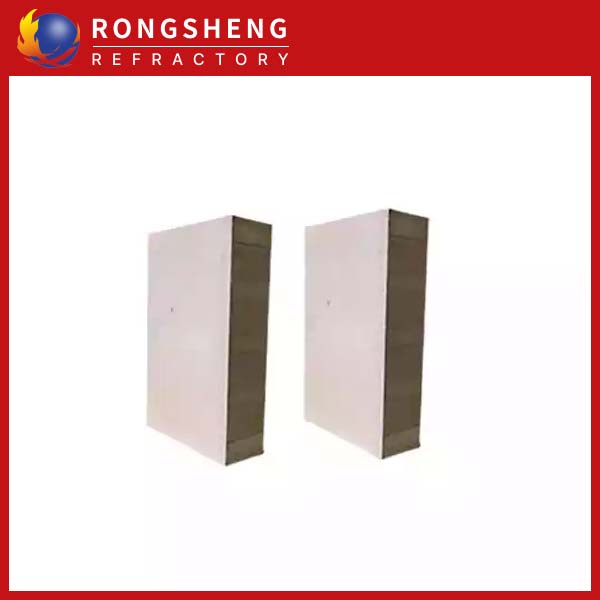

Shipping about zircon brick

Zircon bricks are packaged on wooden pallets before transportation, and the factory delivery time is generally 7-12 dagen, and customized products will take a little longer time.

Why choose us?

De fabriek is opgericht voor 20 years and has 20 senior refractory engineers. The factory can provide a complete set of refractory materials for refractory kilns. The factory produces 80,000 tons of shaped refractory materials and 50,000 tons of unshaped refractory materials yearly.

Rongsheng Vuurvaste Fabriek

Rongsheng Vuurvaste Fabriek

WeChat

Scan de QR-code met wechat