Performance of Magnesia-Calcium Bricks for AOD Furnace

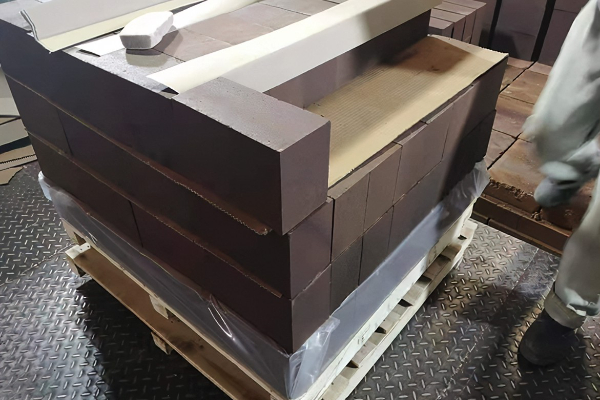

Magnesia-calcium brick is also called high-calcium magnesium brick. It is a magnesium refractory material. It has low porosity. The refractoriness under load temperature is generally higher than 1700℃, and it has good resistance to alkaline slag. It is made of calcium-magnesia sand, crushed, mixed, and formed, and then fired at a high temperature of 1550-1600℃. Magnesia-calcium brick is mainly used as the lining of the AOD furnace and the lining of the VOD ladle for smelting stainless steel, replacing the original magnesia-chrome brick, and is the most important magnesium-calcium refractory material.

Characteristics of magnesia-calcium bricks in AOD furnace

Refraktori yang tinggi

Magnesia-lime bricks are mainly composed of high-purity magnesium oxide (MgO) and calcium oxide (CaO). They have extremely high refractoriness (usually over 2000°C) and can withstand the high-temperature environment in the AOD furnace.

Excellent resistance to slag erosion

Alkaline slag resistance: The calcium oxide component can effectively resist the erosion of alkaline slag and is suitable for processing high-alkalinity slag.

Permeability resistance: High density and low porosity reduce the penetration of slag and metal melt, extending the service life of the brick.

Good thermal shock stability

Magnesia-lime bricks have high thermal shock resistance and can withstand frequent temperature changes in the AOD furnace (such as oxygen blowing and cooling processes).

Purification capacity of molten steel

Calcium oxide (CaO) can react with impurities such as sulfur (S) and phosphorus (P) in molten steel to purify the molten steel and improve its quality.

Anti-peeling

Magnesia-calcium bricks have good volume stability at high temperatures and are not prone to spalling due to thermal expansion or contraction.

Perlindungan alam sekitar

Magnesia-calcium bricks do not produce harmful substances during use and meet environmental protection requirements.

Shortcoming

Easy to hydrate: Calcium oxide components easily react with water (hydrate), so it need to be strictly protected from moisture during storage and transportation.

High cost: High-purity raw materials and complex production processes lead to high costs.

Kilang Refraktori Rongsheng

Kilang Refraktori Rongsheng

WeChat

Imbas Kod QR dengan wechat