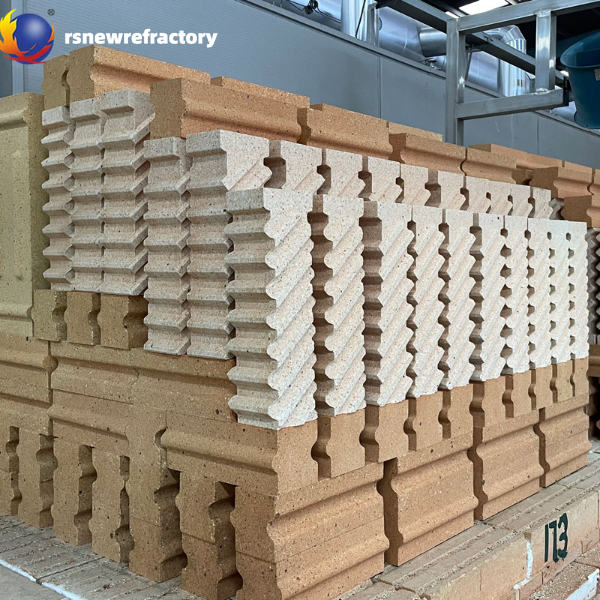

Klasifikasi batu bata refraktori anchor

Anchor refractory bricks are a special material widely used in high-temperature industrial furnaces to support and fix the refractory lining structure. Due to its unique design, anchor bricks can effectively improve the strength and stability of the refractory lining and extend the service life of the equipment. This article will introduce in detail the classification of refractory anchor bricks and their specific applications in industry.

Klasifikasi batu bata refraktori anchor

High alumina anchor brick

Raw Materials: High alumina bauxite is the main raw material, and the alumina content is usually above 48%.

Features: It has good high-temperature resistance and corrosion resistance, and is widely used in the steel industry and cement kilns.

Permohonan: Used in areas where high strength and wear resistance are required in high-temperature kilns.

Clay anchor bricks

Raw materials: Refractory clay is the main raw material, with relatively low alumina content.

Features: High-cost performance, suitable for medium-temperature kilns or low-heat load areas.

Permohonan: Applied to lining fixation of small and medium-sized kilns.

Corundum anchor brick

Raw materials: fused corundum or sintered corundum as the main raw materials, with an alumina content of more than 90%.

Features: extremely strong corrosion resistance and wear resistance, excellent temperature resistance.

Permohonan: used in high-temperature industrial kilns that require extremely high-temperature resistance and corrosion resistance.

Silicon carbide anchor brick

Raw materials: Silicon carbide is the main component, usually with some binder added.

Features: strong wear resistance, excellent thermal conductivity, excellent thermal shock resistance.

Permohonan: Suitable for cooling areas of high-temperature kilns and areas that require rapid heat dissipation.

Application fields of refractory anchor bricks

Steel industry

Applied to fix the refractory lining of blast furnaces, electric arc furnaces, and converters, and withstand the erosion of high-temperature molten metal and slag.

Cement industry

Used in cement rotary kilns, decomposition furnaces,s, and other parts to fix refractory castables and refractory bricks.

Industri kaca

Used in the heat storage chamber and kiln roof of glass kilns to support the kiln structure and resist the erosion of high-temperature gases.

Petrochemical industry

Used in high-temperature devices such as cracking furnaces and gasification furnaces to fix refractory castables and insulation layers.

Other fields

Including high-temperature kiln equipment such as ceramic kilns, waste incinerators, and aluminum industrial furnaces.

Kilang Refraktori Rongsheng

Kilang Refraktori Rongsheng

WeChat

Imbas Kod QR dengan wechat