The difference between black silicon carbide and green silicon carbide

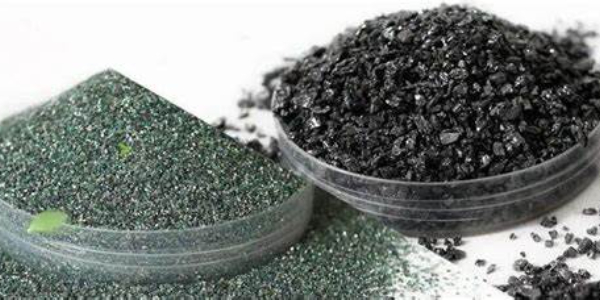

Silicon carbide comes in two colors, black silicon carbide and green silicon carbide. What is the difference between these two kinds of silicon carbide?

Introduction to black silicon carbide and green silicon carbide

There are two commonly used basic varieties of silicon carbide: green silicon carbide powder and black silicon carbide powder, both of which belong to α-SiC. Green silicon carbide and black silicon carbide are basically the same, except for the differences in raw materials and manufacturing processes. The product is green and translucent, and its hardness and purity are better than black silicon carbide. Its elasticity coefficient reaches 410GPa, and it will not dissolve under normal temperature and pressure. It will be lost only when the temperature reaches above 1600°C, and will not decompose until it reaches 2815.5°C.

The difference between the two types of silicon carbide powder

- Black silicon carbide contains about 98.5% SiC, and its toughness is higher than green silicon carbide. It is mostly used to process materials with low tensile strength, such as glass, seramik, stone, bahan refraktori, cast iron, and non-ferrous metals.

- Green silicon carbide contains more than 99% SiC and has good self-sharpening properties. It is mostly used for processing cemented carbide, titanium alloy, and optical glass. It is also used for grinding cylinder liners and precision grinding of high-speed steel tools. Selain itu, there is cubic silicon carbide, which is a yellow-green crystal produced by a special process. The abrasive tools used to make it are suitable for ultra-finishing of bearings, and can make the surface roughness from Ra32 ~ 0.16 microns to Ra0.04 ~ 0.02 microns.

- Chemical coefficient of green silicon carbide: Due to its stable chemical properties, high thermal conductivity, small thermal expansion coefficient, and good wear resistance, in addition to being used as abrasive, it has many other uses; it is used to make advanced refractory materials that are resistant to thermal shock. , small size, lightweight, high strength, and good energy-saving effect.

- .Green silicon carbide is suitable for grinding copper, brass, aluminium, gemstones, optical glass, seramik, and other hard alloys, metals, and hard and brittle non-metallic materials. Its micro powder can also be used as ceramic materials. Due to its high purity, black silicon carbide is also widely used in the manufacture of refractory materials and various abrasive tools.

- Black silicon carbide is made from quartz sand, petroleum coke, and high-quality silica as the main raw materials, and is smelted at high temperature in a resistance furnace. Its hardness is between corundum and diamond, its mechanical strength is higher than corundum, and it is brittle and sharp.

Kilang Refraktori Rongsheng

Kilang Refraktori Rongsheng

WeChat

Imbas Kod QR dengan wechat