Te rereketanga i waenga i nga pereki silica me nga pereki semi-silica

In the refractory industry, silica bricks and semi-silica bricks are two common high-temperature materials. They are widely used in steel, sima, fertilizers, and other high-temperature industrial equipment. Although these two materials are both silicate refractory materials, they have some significant differences in composition, mahi, and application fields. Understanding these differences can help you choose the most appropriate material for your specific needs. This article will delve into the main differences between silica bricks and semi-silica bricks.

Silica bricks and semi-silica bricks have different compositions

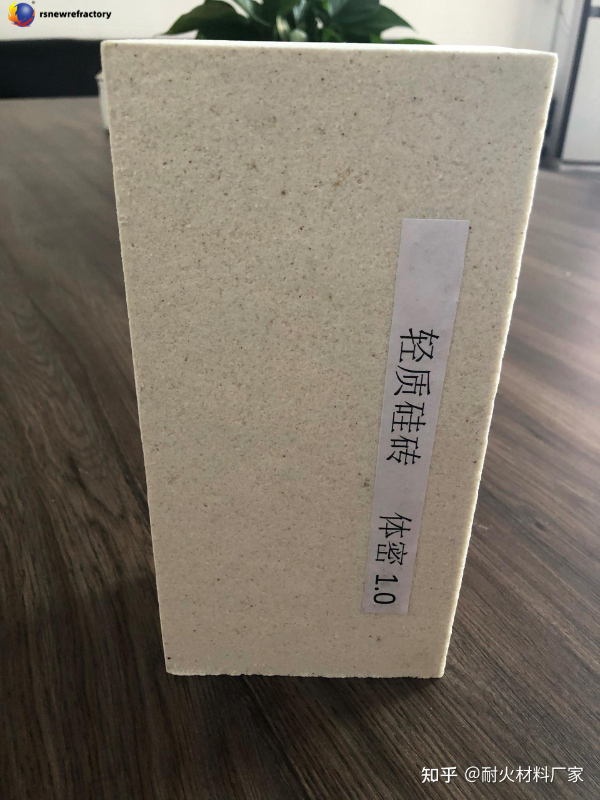

Pereki silica is a refractory material mainly made of raw materials such as silica, quartz, dolomite, etc. Its main component is SiO2. Ko te tikanga, silica bricks are obtained by high-temperature calcination.

Semi-silica bricks are made by adding a certain amount of additives such as alumina and magnesium oxide to silica bricks and through a special molding process. No reira, the SiO2 content in semi-silica bricks is relatively low, but its material properties are further enhanced.

Differences in performance

Silica brick has extremely high heat resistance and chemical stability and is a very excellent refractory material. It has high-pressure resistance, wear resistance, KAUPAPA KAUPAPA, and other characteristics, and performs well in high-temperature environments. No reira, silica bricks are widely used in high-temperature occasions such as furnace walls, furnace bottoms, and kiln walls.

Compared with silica bricks, semi-silica bricks are more suitable for use in some special environments. After adding additives such as alumina and magnesium oxide, the material is finer and has higher fire resistance and heat resistance. The refractoriness, vertical hot and cold cycle performance, compressive strength, and other aspects of semi-silica bricks are better than silica bricks.

The difference between the use of silica brick and semi-silica brick

Silica bricks are suitable for the construction of thermal equipment and thermal barriers in high-temperature environments and are often used in high-temperature places such as chimneys, kilns, and furnaces.

Semi-silica bricks are widely used in chemical, merllurgical, karaihe, ceramic, and other industries, such as pressure crucibles and discharge electrodes in the germanium pulling section. I tua atu, semi-silica bricks can also be used as insulation materials and anti-corrosion flue linings.

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat