Ko nga mea whakamaarama i roto i nga oumu karaihe

Refractory materials are the main components of glass melting furnaces, which have an important impact on glass quality, energy consumption, and product costs. Rongsheng Refractory Factory has been committed to researching nga mea whakaahuru for the ahumahi karaihe. The following is an introduction to the refractory materials commonly used in the glass industry.

Zircon refractory products

Zircon refractory products include high-density zircon refractory bricks, dense zircon refractory bricks, and ordinary zircon refractory bricks. High-density and dense zircon bricks are made by isostatic pressing technology. The products have excellent properties such as high-temperature resistance, te kaha nui, me te ātete ki te horo wai karaihe. They are mainly used in the bottom bricks, channel bricks, flow channel bricks, backing bricks, pereki matau, brushed bricks, and other parts of alkali-free glass tank kilns. Ordinary zircon refractory bricks can be used for the flame space upper structure of the melting pool of alkali-free glass, borosilicate glass, lead glass, soda-lime glass, electronic optical glass kilns, gap bricks between silica bricks and electric fused AZS, observation hole bricks, pereki thermocouple, bottom sublayers and backing bricks.

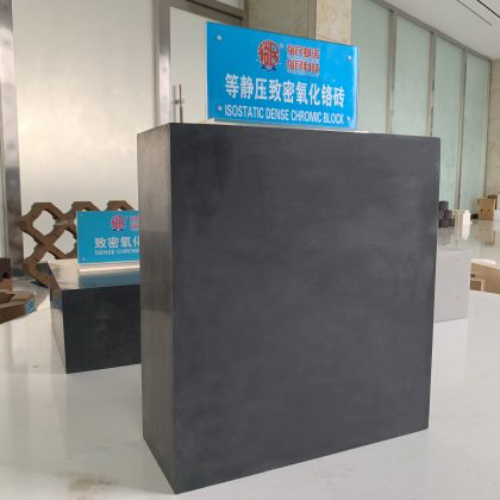

Chromium oxide refractory products

Chromium oxide refractory brick products include dense chromium oxide bricks and aggregate chromium oxide bricks. They are all made by isostatic pressing technology. The products have strong resistance to glass liquid erosion. Dense chromium oxide bricks are mainly used in glass fiber kiln furnaces with severe erosion, including flow holes, melting pools and clarification pool walls, pool bottom paving bricks, charging ports, corner bricks, channel bricks, flow trough bricks, etc.; aggregate chromium oxide refractory bricks have slightly better thermal shock resistance and can be used for glass fiber kiln flow holes, charging ports, climbing bricks, flow trough bricks, etc., and can also be used for certain colored glass flow holes, kiln sill bricks and high erosion areas.

Basic refractory products

Alkaline refractory products mainly include pereki magnesia, magnesia-alumina bricks, magnesia-zirconium bricks, a pereki magnesia-chrome. Various products are divided into different grades. This type of product has excellent resistance to alkali erosion. Magnesia-alumina bricks, magnesia-zirconium bricks, and magnesia-chrome bricks have better thermal shock stability than magnesia bricks and are mainly used in different parts of the heat storage chamber of the glass kiln.

Synthetic sillimanite, mullite, corundum mullite, and zirconium composite products

The synthetic sillimanite, mullite, corundum mullite, and zirconium composite products produced by Rongsheng Refractory Factory have excellent thermal shock stability and resistance to glass liquid erosion. Sillimanite bricks are mainly used for glass kiln feeders and regenerator grate arches; fused mullite, corundum mullite, and zirconium mullite have higher operating temperatures and corrosion resistance and can be used for the upper structure of the melting pool, the bottom of the pool and the upper part of the regenerator.

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat