Silicon carbide crucible is mainly made of silicon carbide as the main raw material, clay or other components (reaction sintering) as the binder, and plastically formed.

The characteristics and application of silicon carbide crucible

Silicon carbide crucible has the characteristics of high strength, wear resistance, erosion resistance, good corrosion resistance, high thermal conductivity, tino pai te parenga waiariki, etc., and is widely used in powder metallurgy and battery negative electrode material calcination and other fields.

Types of crucibles

Crucibles are mainly divided into two types, oxide crucibles, and graphite crucibles. Oxide crucibles mainly include alumina crucibles, magnesia crucibles, clay crucibles, ash dishes, etc. Graphite crucibles mainly include high-purity graphite crucibles, graphite silicon carbide crucibles, and silicon carbide crucibles

How to extend the life of a silicon carbide crucible?

- Selecting only the size crucible that matches your application is the first step in ensuring a long-lasting crucible experience

- Keep careful records of crucible usage and inspect crucibles frequently. Accurate documentation of crucible usage is critical to the effective use and safe operation of crucibles.

- Control scum buildup with regular cleaning. Frequent removal of scum and slag is required.

- Prevents chemical attack by minimizing the use of flux, which can only be added after the metal is completely melted.

- Each crucible has a maximum temperature limit. If this limit is exceeded, the crucible will be damaged and may malfunction.

- Preheating the SiC graphite crucible prevents thermal shock. Crucibles require careful preheating. Thermal shock can cause cracks in crucibles that heat too quickly.

- While installing the crucible is quick and easy, care must be taken to follow instructions regarding base dimensions, clearance between the crucible and furnace, and initial preheating of the crucible.

- Silicon carbide graphite crucibles should be cleaned and stored properly after each use. Avoid stacking crucibles on top of each other, this practice will damage the crucibles.

What is the difference between a graphite crucible and a silicon carbide crucible?

The difference between the two crucibles is that the material composition of the crucible is different. The graphite crucible is mostly made of graphite material, while the silicon carbide crucible is mainly made of silicon carbide. Graphite crucibles are designed for melting metals such as gold, silver, copper, and aluminum. Silicon carbide crucibles are used in large induction furnace melting and are durable and will not oxidize or decompose.

Rongsheng crucible manufacture

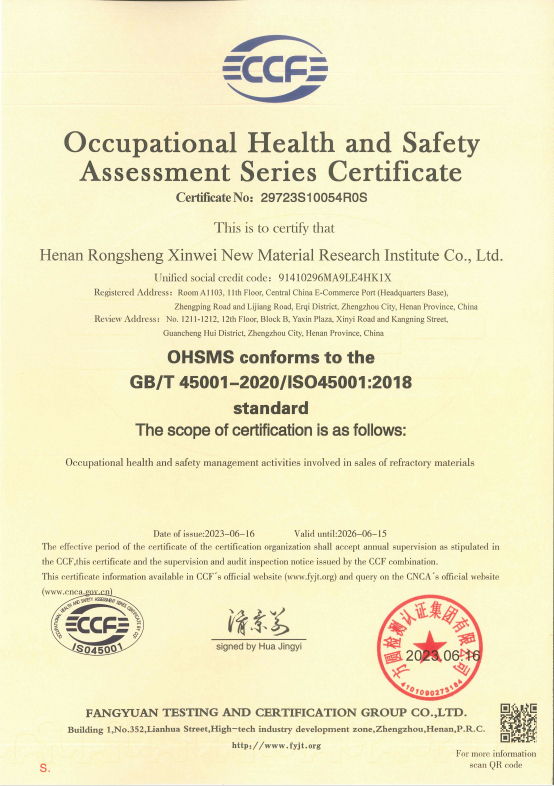

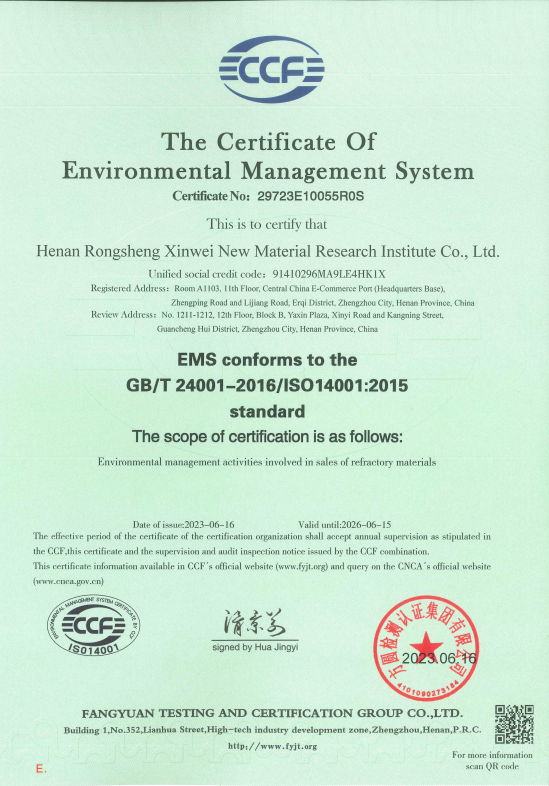

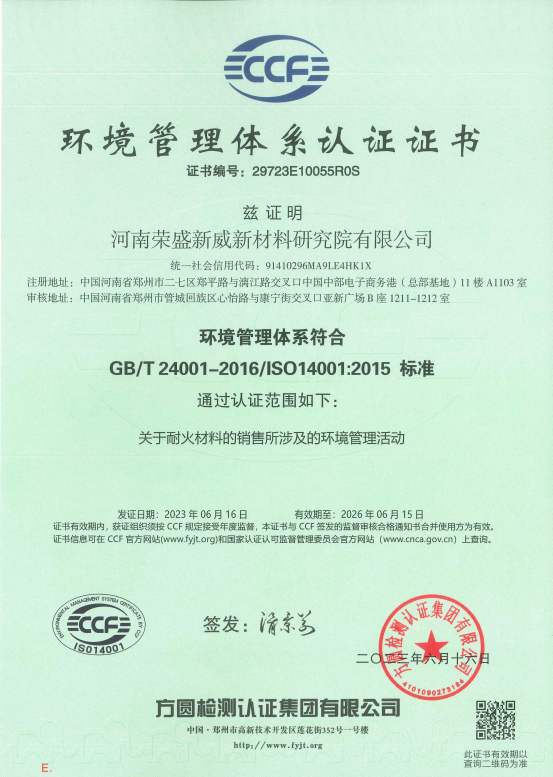

Certificate display

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat