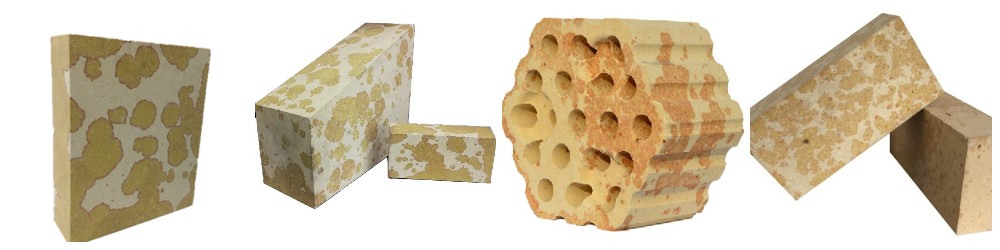

Silica brick is made of quartz stone material, the content of SiO2 is above 93%, and it has good resistance to acid slag and good heat conductivity. The refractoriness is 1690~1710°C, RUL is beyond 1620°C.

Silica fire brick parameters

| Iitem | Taurangi | ||||

| BG-96A | BG-96B | BG-95 | JG-94 | GZ-94 | |

| Sio2% | ≥96 | ≥96 | ≥95 | ≥94.5 | ≥94 |

| Fe2o3% | ≤0.6 | ≤0.8 | ≤1.0 | ≤1.2 | ≤1.4 |

| Melt Index % | ≤0.5 | ≤0.7 | / | / | / |

| Ka kitea te porosity % | ≤21 | ≤22 | ≤22 | ≤22 | ≤24 |

| True Density g/cm3 | ≤2.34 | ≤2.33 | ≤2.35 | ||

| Normal Temperature Compressive Strength MPa | ≥40 | ≥35 | ≥30 | ≥40 | ≥30 |

| 0.2MPa Load Softening Start Temperature℃ | ≥1680 | ≥1670 | ≥1670 | ≥1650 | ≥1650 |

| Heating Permanent Line Change %1450℃*2h | 0-0.2 | / | |||

| Residual Quartz % | ≤3 | ≤1.5 | / | ||

The scope of application of silica bricks

He rauemi whakaahuru waikawa, with strong resistance to acidic slag or acidic solution corrosion, but poor resistance to alkaline corrosion; high load softening temperature, reaching 1640~1680℃; poor thermal shock resistance, refractory degree 1690~1730℃, mainly used for coke Furnaces, hot blast furnaces, glass kilns, carbon roasting furnaces, etc.

Characteristics of silica brick

- High softening temperature under load.

- High thermal conductivity.

- Good thermal shock resistance at high temperatures.

- High-temperature volume stability.

Silica brick shipment

When an order is received, our factory will start production immediately. The specific delivery date needs to be determined according to the order quantity. We will produce silicon refractory bricks in strict accordance with customized requirements.

Rongsheng Kamupene Whakataki

Ko te Kamupene Rongsheng he kaiwhakarato ngaio o nga taonga whakaheke, me 10 tau o te wheako kaweake, Te kawe mai i te neke atu i te 80 whenua. Ko nga hua matua o te kamupene rongsheng kei roto i nga momo pereki whakaraerae, nga mea whakaahuru kore ahua, Nga rauemi metallurgical, thermal insulation materials, me etahi atu.

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat