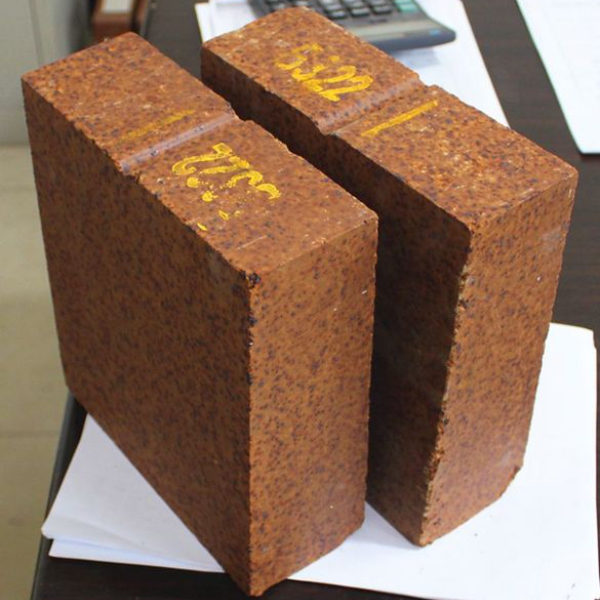

Magnesia-alumina spinel brick is made of magnesia-alumina spinel ((MgAl2O4 abbreviated as MA)) as the matrix, using high-quality high-purity magnesia and Al2O3-containing ore, through batching, mixing, billet making, whakamaroke, firing and other processes. Alkaline refractory products are known for their superior thermal shock resistance to magnesia bricks and are widely used in masonry cement rotary kilns, lime rotary kilns, open hearth furnaces, electric furnace roofs, etc.

Magnesium aluminum spinel brick parameters

| Tūemi | Taurangi | |||

| MLJ-90 | MLJ-85 | MLJ-80 | MLJ-75 | |

| MgO % | ≥90 | ≥85 | ≥80 | ≥75 |

| Ko Al2O3 % | 3~8 | 5~12 | 8~17 | ≥8~12 |

| Te porosity % | ≤17 | ≤17 | ≤16 | ≤19 |

| Bulk density g/cm3 | ≥2.95 | ≥2.95 | ≥2.90 | ≥2.85 |

| Cold Crushing Strength MPa | ≥45 | ≥45 | ≥55 | ≥40 |

| 0.2MPa Refractoriness under load ℃ | ≥1700 | ≥1650 | ||

| Thermal shock resistance cycle 1100℃water cooling | ≥3 | ≥8 | ≥12 | ≥8 |

Magnesia alumina spinel bricks application

Magnesia-aluminum spinel bricks are often used in the transition zone of the rotary kiln, the kiln mouth, the inner lining of the cooler, and other important parts.

Rongsheng Kamupene Whakataki

Rongsheng Company is a professional supplier of refractory materials, me 10 tau o te wheako kaweake, Te kawe mai i te neke atu i te 80 whenua. Ko nga hua matua o te kamupene rongsheng kei roto i nga momo pereki whakaraerae, nga mea whakaahuru kore ahua, Nga rauemi metallurgical, Nga taonga whakauru waiariki me era atu.

our service

- Support factory visit

- Support product customization

- Good after-sales service

- Designated refractory solutions

- Samples can be provided

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat