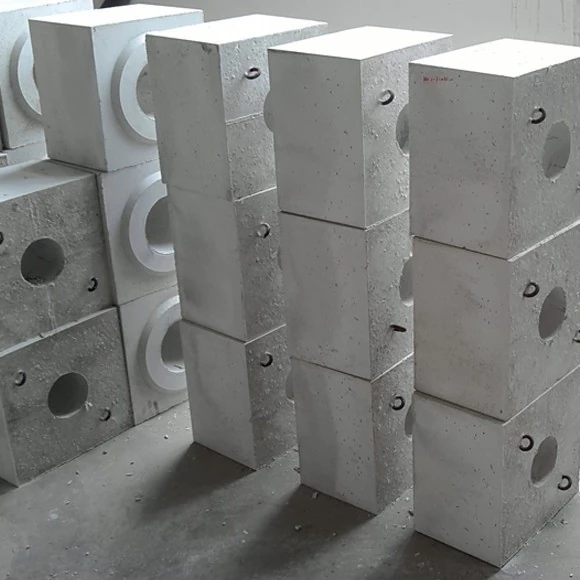

The ladle nozzle brick is made of high-purity raw materials, formed by vibration casting and low-temperature baking, and has the advantages of high thermal strength, Te ātete o te māngaro, corrosion resistance and erosion resistance, and thermal repair.

Nozzle brick parameters

| Tūemi | Taurangi | ||

| Chromium Fused Alumina | Fused Alumina | Corundum Spinel | |

| Ko Al2O3 % | ≥90 | ≥92 | ≥80 |

| Ko Al2O3+MgO % | / | / | ≥92 |

| Cr2O3 % | ≥2 | / | / |

| Bulk density g/cm3 | ≥3.0 | ≥2.95 | ≥2.95 |

| Cold Crushing Strength MPa | ≥60 | ≥50 | ≥50 |

| 0.2MPa Refractoriness under load ℃ | ≥1700 | ≥1700 | ≥1700 |

Features of nozzle bricks

- High refractoriness,

- Te parenga teitei-mahana.

- Good corrosion resistance.

- Good peeling and abrasion resistance.

- Good thermal shock resistance.

- High mechanical strength.

- Low creep rate at high temperature.

- Good volume stability at high temperatures.

The function of ladle nozzle brick

The ladle nozzle brick usually has a special shape to meet the needs of molten steel flow and pouring. When the molten steel flows out of the ladle, the ladle nozzle brick plays the role of diversion, buffer, and diversion, which plays a vital role in ensuring the smooth flow of molten steel and the quality of steel.

Rongsheng hot refractory material products

Rongsheng Company is a company specializing in the export of refractory materials. The company’s various refractory bricks are very popular, especially pereki alumina teitei, pereki waro magnesia, high chrome bricks, pereki corundum, a pereki andalusite. I tua atu, some insulation materials are often purchased by customers, penei ceramic fiber blankets, papa muka uku, etc.

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat