The main raw material of high alumina insulation bricks is bauxite, and the content of aluminum oxide in high alumina insulation bricks is more than 48%. I tenei wa, high alumina refractory bricks are very popular as a kind of heat insulation refractory brick, with compressive strength High, low thermal conductivity, and good thermal insulation performance.

Composition of high-aluminum poly-light insulation brick

| Tūemi | Taurangi | |||||

| LG-1.2 | LG-1.0 | LG-0.8 | LG-0.7 | LG-0.6 | LG-0.5 | |

| Ko Al2O3 % | ≥48 | |||||

| Fe2O3 % | ≤2 | |||||

| Bulk Density g/cm3 | ≤1.2 | ≤1.0 | ≤0.8 | ≤0.7 | ≤0.6 | ≤0.5 |

| Cold Crush Strength,MPa | ≥4.5 | ≥3.5 | ≥2.5 | ≥2.2 | ≥1.6 | ≥1.2 |

| Permanent Linear Change Rate,% | 1400℃×12h ≤-2 | 1350℃×12h ≤-2 | 1250℃×12h ≤-2 | |||

| Thermal Conductivity W/(m·K) 350±25℃ | ≤0.55 | ≤0.50 | ≤0.35 | ≤0.30 | ≤0.25 | ≤0.20 |

Features of high alumina insulation bricks

- Slightly high-temperature resistance.

- Acid and alkali corrosion resistance.

- Good thermal stability.

- Good insulation performance.

- Low thermal conductivity.

- Significant energy-saving effect.

The use of high alumina refractory bricks

High alumina refractory bricks have a good heat insulation effect and can be applied to the thermal insulation layer of thermal contact furnaces and hot blast furnaces. High alumina poly-light bricks are also widely used in coking furnaces and heating furnace thermal equipment in the metallurgical industry.

Precautions for the use of high alumina bricks

Storage: High alumina bricks should be stored in a dry and ventilated place, avoiding contact with water or moisture, so as not to affect its performance. Avoid contact with acidic and alkaline substances to prevent chemical reactions.

Cutting: High alumina bricks can be cut by mechanical equipment or by hand, but care should be taken not to break or crack when cutting, otherwise it will affect its use effect.

Installation: High-alumina bricks need to be fixed with high-temperature refractory glue or refractory mortar. The dust and impurities on the installation surface should be cleaned before installation to ensure that the glue or mortar can be firmly bonded.

Maintenance: High alumina bricks may be subjected to mechanical shock or chemical attack during use, and regular maintenance is required. If it is cracked or damaged, it should be replaced in time.

High alumina insulation brick delivery

I muri i te whiwhi i te ota, the factory will produce it immediately and generally ship it within 7-12 days. It will take longer to customize the size of high-alumina insulation bricks.

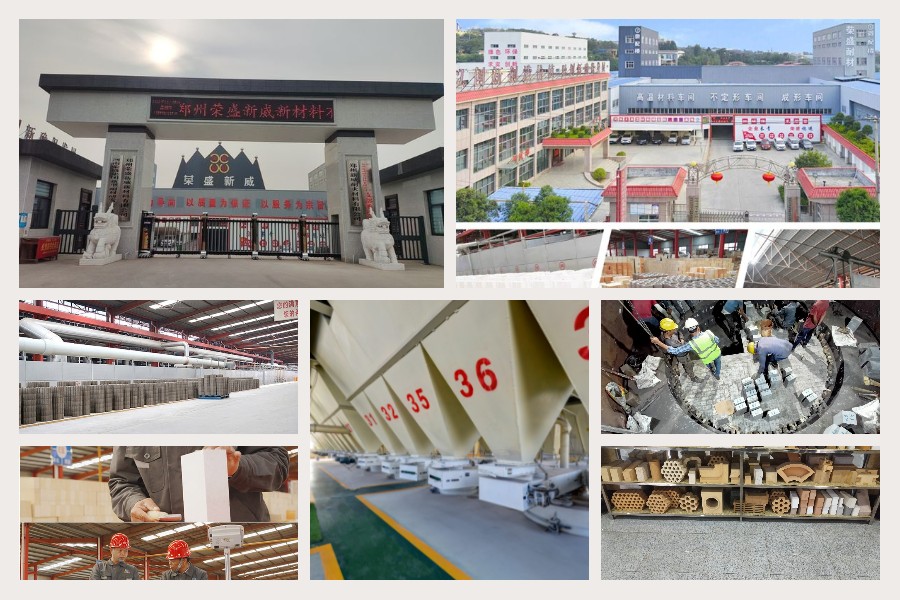

Introduction of Rongsheng

Rongsheng has been established for 20 years and has been exported to more than 80 whenua, such as Russia, Indonesia, South Africa, Egypt, and other countries. The raw materials produced by the refractory material factory include pereki whakaahuru, insulation bricks, nga rauemi mata kino and metallurgical raw materials, etc., which are widely used in the ahumahi maitai, iron industry, ahumahi whakarewa kore-ferrous, ahumahi karaihe, and power industry.

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat