Ko te whakaurunga o nga taputapu whakamaarama o te pune

The ladle is an essential piece of equipment for continuous casting. It is a container for carrying and holding molten steel from tapping to pouring. The spoon is also called a ladle, which carries molten steel and refining outside the furnace. The refractory materials used in different structures of ladles are also different. The following is a specific introduction to ladle refractory materials.

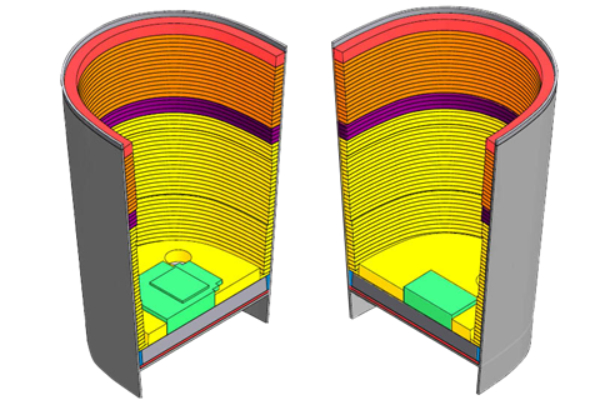

Ladle structure

The ladle is composed of a barrel body, lining, nozzle opening and closing device, and ventilation bricks. From the outside to the inside, the inner lining consists of three layers: the heat insulation layer, the middle layer, and the working layer; The material part, the nozzle device, the seat brick, and the breathable brick and other parts.

Ladle bottom refractory material

The refractory material at the bottom of the ladle is clay brick, also known as sintered brick, which is an artificial small block for construction. The clay brick uses clay (including shale, coal gangue, and other powder materials) as the main raw material, and is treated with mud, shaped, and dried. And roasted, there are solid and hollow respectively.

Ladle working layer refractories

Ladle working layer refractory pereki teitei-konumohe, among the refractory materials produced with aluminum-silicon raw materials, the bricks with Al203 as the main component include high-alumina bricks, mullite bricks, and corundum bricks.

Ladle body pouring

Castables for ladles refer to the mixture composed of refractory aggregates, binders, and admixtures, which are mixed with water (or liquid binders) to form mud materials that can be constructed by pouring. The difference from other unshaped refractory materials is that refractory castables have a certain setting and hardening time after construction, so after casting and forming, it takes a certain period of curing before they can be molded, and then they can be put into baking after an appropriate period of natural curing. Grilled use.

Ladle wall refractories

Unburned bricks, also known as chemically bonded bricks. It refers to the refractory material that can be used directly for masonry without firing bricks. Its production process is relatively simple. It uses refractory materials of different materials. The combination of powder and granules in the product is mainly formed by the chemical action of the binder.

Ladle Refined Refractories

If the ladle is also used for refining, it can also be used for refractory materials: pereki zircon, pereki waro magnesia, aluminum magnesia carbon bricks, pereki chrome magnesia, magnesia chrome aluminum bricks, etc.

Ladle use and maintenance

- The refractory bricks must be built according to the reference size in the figure, and the brick joints should be sealed with refractory mud.

- Before use, carefully check whether the connection parts are firm, whether there are cracks and looseness in each stress-bearing part, and whether the transmission part is flexible and reliable. Use it strictly according to the operating regulations after it is clear that the spoon is not damaged.

- For the stopper rod-type ladle, the brake iron bolt should be adjusted for centering adjustment. For sliding nozzle ladles, the nozzle bolts should be adjusted so that the two sliding surfaces are in good contact.

- Before lifting molten steel, the large pallet should be locked. When using, pay attention to whether all parts are in a normal state. If any abnormal situation is found, stop the machine for inspection immediately.

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat