Features of Magnesium-aluminum Spinel Brick for Cement Kiln

To solve the problem of environmental pollution caused by magnesia-chrome bricks used in cement kilns, chromium-free alkaline products have been developed, and magnesium-aluminum spinel brick and magnesia-iron spinel bricks can have very good results when used in cement kilns.

Introduction of magnesia alumina spinel brick

Magnesia-alumina spinel brick is made of magnesia-alumina spinel ((MgAl2O4 abbreviated as MA)) as the matrix, using high-quality high-purity magnesia and Al2O3-containing ore, through batching, mixing, billet making, whakamaroke, firing and other processes. Basic refractory products.

Application of magnesium-aluminum spinel brick

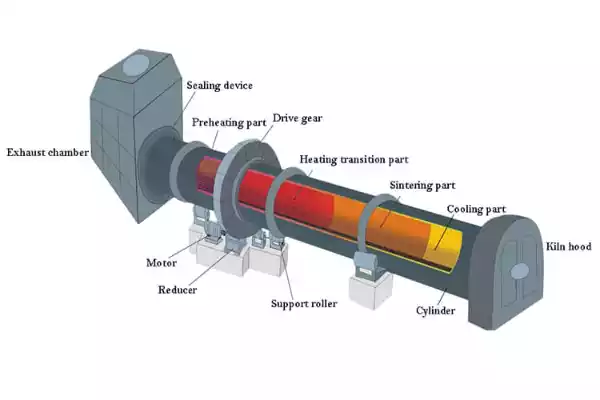

Known for its better thermal shock resistance than magnesia bricks, it is widely used in masonry cement rotary kilns, lime rotary kilns, open hearth furnaces, electric furnace roofs, etc. Due to the characteristics of Alcoa spinel bricks, it has been widely used in Masonry materials for the roof of high-temperature smelting furnaces such as large cement kilns and copper reverberatory furnaces, which have achieved the effect of prolonging the life of the furnace.

Features of magnesia alumina spinel brick

- Magnesium-aluminum spinel brick has good thermal shock stability, can withstand water cooling for 20~25 times, and can withstand air cooling for more than 100 times, or even more. This is its most prominent advantage, much better than ordinary magnesia bricks.

- The performance of magnesium-aluminum spinel brick is also slightly stronger than that of magnesia bricks. Due to the higher melting point of magnesia-alumina spinel itself, the load softening temperature of magnesia-alumina bricks is improved compared with magnesia bricks, reaching 1650 ~ 1700 ℃

- The ability of magnesium aluminum spinel to protect periclase particles from slag erosion is stronger than that of calcium magnesium olivine, so the ability of magnesium aluminum spinel bricks to resist alkaline slag and iron oxide slag is better than that of magnesia bricks.

Why do magnesia alumina spinel bricks have good thermal shock stability?

The thermal shock stability of magnesia-alumina spinel bricks is good because both magnesia-alumina spinel and periclase belong to the cubic crystal system, and the thermal expansion along each crystal axis direction is the same, so the expansion and contraction are relatively uniform when the temperature fluctuates. Generates less thermal stress.

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat