Ko te papatipu ramming corundum spinel i kaweake ki Bolivia

RS’ corundum spinel ramming mass was successfully exported to Bolivia, providing local customers with high-quality refractory solutions.

Whakataki Whakataki Bolivia

The client is a well-known metallurgical company in Bolivia, focusing on the procurement and processing of iron ore. During the high-temperature smelting process, they require a large amount of refractory materials for repair and protection of the inner wall of the furnace and have strict requirements on the high-temperature resistance and wear resistance of the materials.

About cooperation on corundum spinel ramming materials

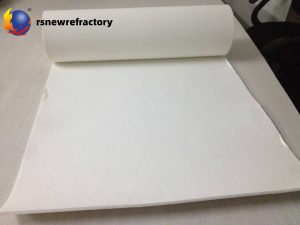

I roto i te korero ki nga kaihoko, we learned about their requirements for ramming materials, including refractoriness, slag resistance, pūmautanga matū, etc. E ai ki nga hiahia o nga kaihoko, we provide corundum spinel ramming materials that meet the standards and provide corresponding technical support and after-sales services.

The effect of using the customer’s ramming material

Customers use our He maha o te rami to repair and protect the inner walls of high-temperature smelting furnaces, which effectively improves the refractory performance and service life of the furnaces and ensures the production efficiency and quality of iron ore.

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat