A Chilean customer ordered a batch of magnesia chrome refractory

No tata nei, an important industrial enterprise in Chile chose Rongsheng Refractories Co., Ltd. as their refractory supplier, and successfully ordered a batch of magnesia chrome refractory.

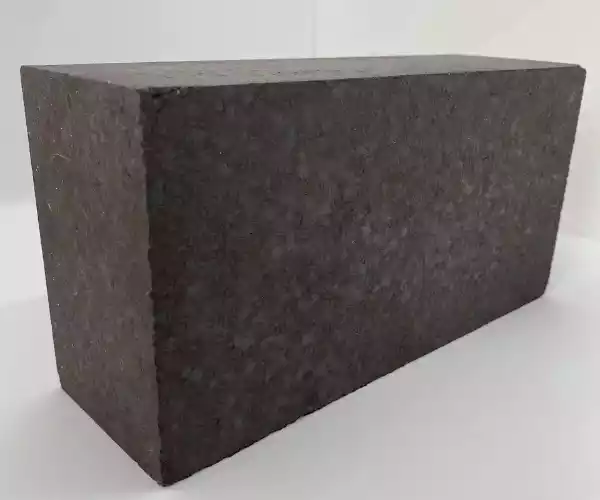

Magnesia chrome brick introduction

Magnesia-chrome bricks are basic refractory products containing 55% to 80% of MgO and 8% to 20% of Cr2O3, which are composed of periclase, composite spinel, and a small amount of silicate phase. Composite spinel includes spinel solid solutions such as MgAl2O4, MgFe2O4, MgCr2O4, and FeAl2O4.

Chile customer introduction

The client is a leading metallurgical company in Chile, specializing in the production and processing of metal products. They enjoy a good reputation in the industry and have strict requirements on product quality and production efficiency.

Chilean customer demand Analysis

Since the customer’s production process involves high temperatures and corrosive environments, they needed a refractory material that could withstand high temperatures, resist corrosion, and have good wear resistance. Customers provide the indicators of magnesia chrome bricks they need in thermal metallurgy, and our factory can customize refractory bricks of different shapes and indicators for customers.

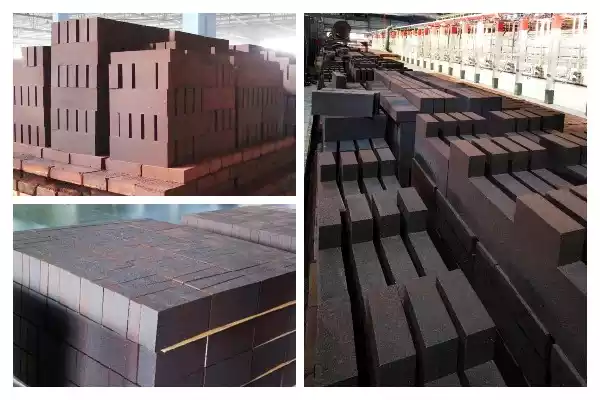

Production of magnesia chrome refractory

After confirmation, the Rongsheng factory started to produce magnesia-chrome bricks according to customer needs. The customer’s order totaled 37,680 US tāra. After the production of our magnesia chromite brick was completed, the factory will conduct a series of product tests and the pereki whakaahuru will be shipped after they pass the test.

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat