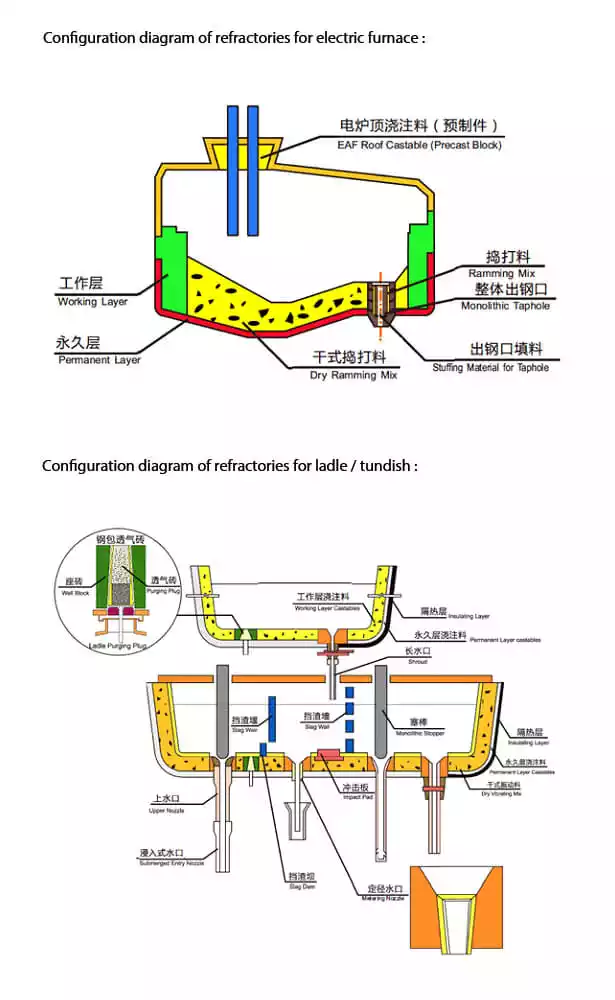

Configuration Diagram of Refractories

Ahumahi Steel

- Refractories for Steel-making Furnace:

Castables and precast blocks for EAF Poof

Castables and precast blocks for LF roof

- Refractories for Ladle & Tundish :

Dry ramming mix for EAF bottom

Dry ramming mix for intermediate Frequency furnace

- Functional refractories for con-casting:

Castables series for ladle lining

Shaped refractories for ladle

Dry vibrating mix for tundish

Coatings series for tundish

Castable for the permanent lining of tuna dish

- Functional Refractories for Con-Casting :

Slag Tile(Weir) and impact pad

Shroud, Monolithic Stopper, and Submerged entry nozzle for billet, slab, thin slab

Continuous casting)

Zirconia metering nozzles for billet Continuous casting

- Refractories for Heating Furnace :

Refractory castables for working lining of the Heating furnace

Plastic refractories for heating furnace

Light-weight insulating castables for Heating furnace

Gunning mix for converter and ladle

Precast chrome corundum abrasion-resistant bock for heating furnace

Refractory fiber products for heating Furnace (felt, blanket, board and module)

- Refractories for converter :

Magnesium carbon brick

Tapping hole block

Overall steel outlet

Gunning mix for tapping hole

Magnesium gunning material

Repair refractory for converter

Filling material for converter steel outlet

Cold joint material for converter

Hot repair material for converter

Magnesia carbon brick :

Magnesia carbon bricks are made of high melting point alkaline oxide magnesium oxide (melting point 2800℃) and high melting point carbon materials that are difficult to be infiltrated by slag as raw materials, adding various non-oxide additives and combining them with carbon binders Do not burn carbon composite refractories. Magnesia carbon brick has good high temperature resistance, kaha te parenga para, good thermal shock resistance and low high-temperature creep.

| Tūemi | MT-8 | MT-12 | MT-14 |

| MgO,% ≥ | 82 | 78 | 76 |

| C,% ≥ | 8 | 12 | 14 |

| Apparent Porosity,% ≤ | 6 | 5 | 4 |

| Bulk Density,g/cm3 ≥ | 2.98 | 2.95 | 2.93 |

| Te Kaha Maeke,MPa ≥ | 30 | 35 | 40 |

| Modules of Rupture(1400*0.5h),MPa ≥ | 5 | 8 | 12 |

pereki Magnesia :

Magnesia bricks have periclase as the main crystal phase, which is the main product in alkaline refractories. It has high refractoriness and good resistance to iron oxides, alkaline slag and high-calcium fluxes.

| Tūemi | MZ-92 | MZ-95 | DMZ-97 | DMZ-98 |

| MgO,% ≥ | 92 | 95 | 96.8 | 97.5 |

| SiO2,% ≤ | 3 | 2.5 | 1.5 | 1.0 |

| CaO,% ≥ | 2.5 | 2.0 | 1.2 | 1.2 |

| Apparent Porosity,% ≤ | 18 | 18 | 16 | 15 |

| Bulk Density,g/cm3 ≥ | 2.92 | 2.95 | 3.10 | 3.15 |

| Te Kaha Maeke,MPa ≥ | 55 | 60 | 70 | 80 |

| 0.2MPa R-U-L ,℃ ≥ | 1550 | 1600 | 1700 | 1700 |

| Te ātete o te māngaro ,1100℃ ≥ | 10 | 10 | 8 | 8 |

Silica Bricks :

Silica brick is made of quartz stone material, the content of SiO2 is above 93%,it has good resistance to acid slag and good heat conductivity. And the refractoriness is 1690~1710°C,RUL is beyond 1620°C.

| Tūemi | RG-95 | ||

| Furnace Wall Bricks | Checker Brick | ||

| Chemical composition | SiO2 | ≥95 | |

| Ko Al2O3 | ≤1.0 | ||

| Fe2O3 | ≤1.2 | ||

| Apparent Porosity % | ≤22 | ≤24 | |

| Real Density g/cm3 | ≤2.33 | ≤2.34 | |

| Cold Crushing Strength MPa | ≥40 | ≥30 | |

| 0.2MPa R-U-L ℃ | ≥1650 | ||

| Te toenga kiripaka % | ≤1.5 | ||

| Creep Rate % 0.2MPa 1500℃ 0h~50h | ≤0.8 | ||

| Thermal expansion rate % 1000℃ | ≤1.28 | ||

Unshaped Refractory For Steel Industry :

| Tūemi | Taurangi | |||

| Aluminum Magnesium Spinel Castable | Corundum spinel Castable | Low Cement High Alumina Castable | Mullite Artesian Castable | |

| MgO,% ≥ | 13 | 3.5 | – | – |

| Ko Al2O3 , % ≥ | 70 | 92 | 70 | 75 |

| Fe2O3 , % ≤ | – | – | 1.2 | 1.0 |

| Real Density,g/cm3 ≥ | 2.8 | 3.1 | 2.8 | 2.75 |

| Modules of Rupture,MPa ≥ | 6 | 9.2 1400℃*0.5h | 9 | 10 |

| Te Kaha Maeke,MPa ≥ | 42 | 64 | 65 | 100 |

| Linear Change Rate,% 1500℃*3h | ±1.0 | 0~0.5 | ±0.6 | 0~-0.5 |

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat