The working environment of CFB boiler is high speed fluidized particles abrasion and impact, chemical reaction and corrosion, frequent thermal exchange. So CFB boiler lining refractory have high mechanical strength, excellent abrasion resistance, good corrosion resistance, good thermal shock resistance and so on.

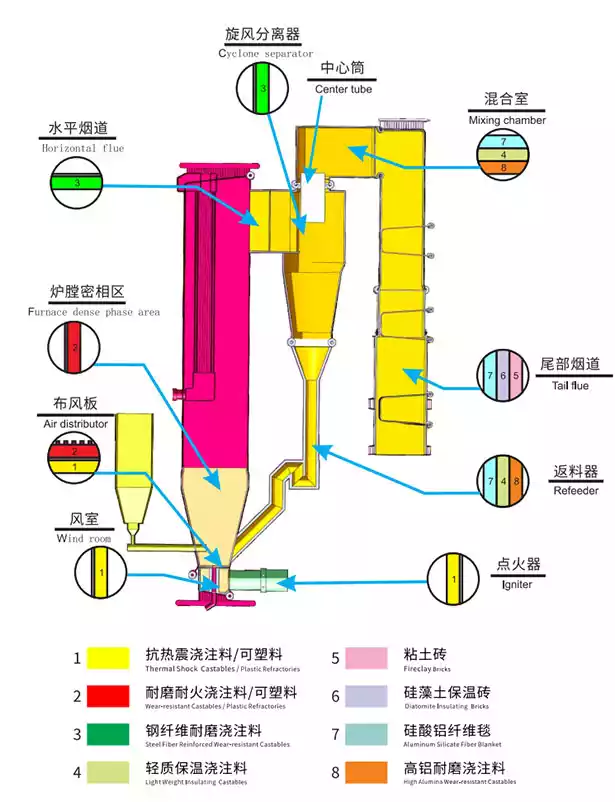

Refractories Conformation Scheme for CFB Boiler

Refractories for CFB Boiler System

- Boiler Combustion Chamber

RSNM-B Castables(Dense phase zone, sparse phase zone, boiler roof and etc.)RSNMKS Plastic Castables(Fluidized section of dense phase zone)

- Air Separation

RSNM-A Castables or RSNM-75 Wear-resistant Bricks(Used on straight part and cone-shaped part of cyclone tube , gateway, refeeder etc.)

- Economizer

RSZGN-42 Refractory Bricks

RSNM-75 Wear-resistant Bricks

RSNM-A Dense Castables

RSQZ -0.7 Light Weight Castables

RSQZ -0.3/0.6 Light Weight Insulating Products

RSNT-2 Castables(Beam of economizer)

RSXWT-100 Refractory Fiber Blanket

- Ignition Air Flue、Cold Air Chamber

RSJZL -1 Castables

RSNT-2 Castables

- The Tail Flue

RSNM-B Castables

RSQZBW -650/1000 Light Weight Insulating Products

RSZGN-42 Refractory Bricks

- Unshaped Refractory Materials

Unshaped refractory is most important refractory used in CFB boiler, it accounts for 70%~80% of the total amount. Low cement castable, ultra low cement abrasion resistant castable and no cement wearing resistant castable are usually used in circulating fluidized bed boiler.

Wear-resistant Castables

The wear resistant castables, made from fused corundum, super grade bauxite, sillimanite, alumina powder and silicon powder as raw materials, are featured with convenient construction, good wear esistance,good spalling resistance, and high strength at early and mid-high temperature period, which overcome the disadvantages of traditional castables.

| Tūemi | Specification | |

| Bulk Density, g/cm³ | 110℃ ×24h | ≥2.75 |

| Permanent Linear Change On Heating , % | 1100℃ ×3h | ±0.4 |

| CCS , MPa | 110℃ ×24h | ≥100 |

| 1100℃ ×3h | ≥120 | |

| CMOR , MPa | 110℃ ×24h | ≥10 |

| 1100℃ ×3h | ≥18 | |

| Thermal Shock Resistance,Cycle | 1000℃ Water Quenching | ≥20 |

| Wear-resistance Index,cc | ASTM C-704 | <6 |

| Hangahanga matū , % | Ko Al2O3 | ≥75 |

| SiO2 | <18 | |

| Maximum Service Temperature,℃ | 1600 | |

| Service Area | Dense phase area and transition area of combustion chamber, furnace bottom, cyclone cylinder outlet mixing chamber. | |

Steel Fiber Reinforced Wear-resistant Castables

The castables are produced by adding some silicon carbide, mullite and steel fiber, to enhance the tensile property, strength and thermal shock resistance on the basis of the technology of optimized wear resistance castables. It is used in cutting direction entrance of cyclone separator and “target area” on cartridge of circulating fluidized bed boiler, which are the worst wear parts.

| Waitohu | RSNM-A | |

| Tūemi | Specification | |

| Bulk Density , g/cm³ | 110℃ ×24h | ≥2.8 |

| Permanent Linear Change On Heating , % | 1100℃ ×3h | ±0.4 |

| CCS , MPa | 110℃ ×24h | ≥100 |

| 1100℃ ×3h | ≥120 | |

| MOR , MPa | 110℃ ×24h | ≥17 |

| 1100℃ ×3h | ≥20 | |

| Thermal Shock Resistance,Cycle | 1000℃ Water Quenching | ≥25 |

| Wear-resistance Index,cc | ASTM C-704 | ≤5 |

| Hangahanga matū,% | Ko Al2O3 | ≥80 |

| SiO2 | <11 | |

| Maximum Service Temperature,℃ | 1600 | |

| Service Area | Horizontal flue at furnace outlet, straight part and cone-shaped part of separator ,entry and exit, refeeder and dipleg etc. | |

Wear-resistant Plastic Refractories

Compared with the traditional refractory plastic,the wear resistant plastic refractories are featured with good plastic ability, long shelf life,high strength and good wear resistance. The strength of the material increases with the increasing temperature due to the adoption of composite binder. The wear-resistant plastic refractories,using fused corundum,mullite and super grade bauxite as main raw materials,the addition of Guangxi white clay ensures that the refractory plastic can have high plasticity, enhance the crushing strength and wear resistance, especially suitable for repairing CFB boilers and the overall construction of wear resistant lining. Refractory plastic can be processed into non-baking materials, then furnace can be directly start if necessary.

| Waitohu | RSNMKS-A | |

| Tūemi | Specification | |

| Bulk Density , g/cm³ | 110℃ ×24h | ≥2.7 |

| CCS , MPa | 110℃ ×24h | ≥80 |

| 1100℃ ×3h | ≥100 | |

| MOR , MPa | 110℃ ×24h | ≥12 |

| 1100℃ ×3h | ≥14 | |

| Hangahanga matū , % | Ko Al2O3 | ≥80 |

| Maximum Service Temperature , ℃ | 1600 | |

| Wear-resistance Index,cc | ASTM C-704 | ≤6 |

| Service Area | Wear resistant parts,such as dense phase area, overheating screen, separator target area, horizontal flue etc. | |

Thermal Shock Resistant Castables

Most CFB furnaces are ignited under the bed, the ignition temperature is high, and the temperature rises rapidly after ignition; The oil gun will be turned off after the boiler reaches 650 degrees, and the temperature will drop to 150 degrees instantaneously. No reira, thermal shock resistant and high refractoriness are required, especially in the air chamber, igniter, and water-cooled air chamber. Thermal shock resistant castable is the best choice for these areas.

| Waitohu | RSKRZ-1 | |

| Tūemi | Specification | |

| Bulk Density,g/cm³ | 110℃ ×24h | ≥2.8 |

| CCS,MPa | 110℃ ×24h | ≥100 |

| 1100℃ ×3h | ≥120 | |

| MOR,MPa | 110℃ ×24h | ≥17 |

| 1100℃ ×3h | ≥20 | |

| Thermal Shock Resistance,Cycle | 1000℃ Water Quenching | ≥25 |

| Maximum Service Temperature,℃ | 1600 | |

| Service Area | Igniter, ignition air flue, water cooling chamber | |

Fireclay Castables

| Waitohu | RSNTJ-2 | |

| Tūemi | Specification | |

| Bulk Density,g/cm³ | 110℃ ×24h | 2.2-2.4 |

| CCS,MPa | 110℃ ×24h | ≥40 |

| 1100℃ ×3h | ≥50 | |

| MOR,MPa | 110℃ ×24h | ≥5 |

| 1100℃ ×3h | ≥6 | |

| Thermal Shock Resistance,Cycle | 1000℃ Water Quenching | ≥20 |

| Maximum Service Temperature,℃ | 1400 | |

| Service Area | Ignition duct, mixing chamber, coal economizer beam | |

Rongsheng Refractory Factory

Rongsheng Refractory Factory

WeChat

Matawai te Waehere QR me te wechat