What is the difference between low cement castable and cement free castable?

Refractory castable is widely used as a kind of unshaped refractory material. Cement-free castable and low-cement castable are two common types of castables with significant differences in composition, performance, and usage scenarios. This article will introduce in detail the differences between cement-free castables and low-cement castables to help you better choose suitable refractory materials.

What is cement-free castable?

Cement-free castables do not use high-alumina cement as a binder. They are high-temperature-resistant castables that rely on sol, resin, phosphoric acid, water glass, etc.

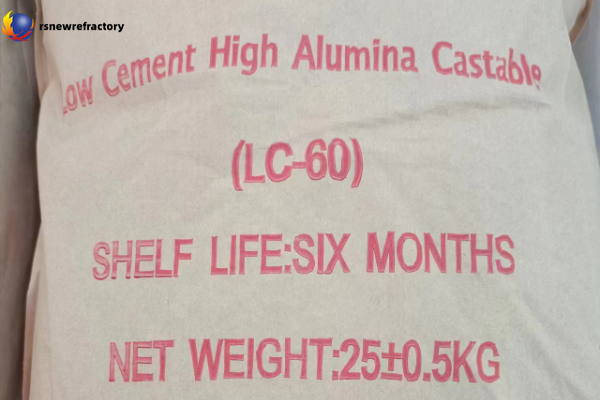

What is low cement castable?

Low cement castables contain less cement (usually 3% to 8%), much lower than traditional castables. This castable has the characteristics of low calcium content and high strength in later use.

Difference between low cement castable and cement-free castable

Cement-free castables do not contain traditional cement binders but use ultrafine powder and specific chemical binders. Its characteristic is that it achieves sintering and bonding effects through chemical reactions at high temperatures.

Low-cement castables contain fewer cement components (generally 3% to 8%), and the cement content is greatly reduced compared to traditional castables. This feature brings higher density and better high-temperature resistance.

Cement-free refractory castables use sol as a binder, so the impurity content is low. The refractoriness and slag erosion resistance of the castable will not decrease, which helps to increase the temperature and internal structural strength.

In addition, cement-free castables rely on the addition of dispersants and delayed-acting accelerators to give the castables a certain fluidity. After vibration molding during construction, they are coagulated by accelerators. For example, castables combined with phosphoric acid have high use temperatures and better strength.

The raw material composition of low-cement castables is basically the same as that of cement-free castables, except that the binder is combined with high-aluminum cement. Low-cement castables have an additional amount of high-aluminum cement of less than 6%, and general castables have an additional amount of high-aluminum cement of 12-15%. The additional amount of lightweight castables will be higher.

Low-cement castables are combined with calcium aluminate cement. During construction, the aggregate is mixed first, followed by the binder. A certain proportion of drinking water must be added. Cement-free castables have a slow setting speed. For example, for castables with phosphoric acid as a binder, the binder must be added twice and cannot be added all at once. First, add a part, and after the material is trapped for 10 hours, add another part of the binder before it can be put into use.

Whether it is cement-free castables or low cement castables, they are determined according to different usage conditions and temperatures. The thickness and construction location of the construction must also be considered, and different forms of castables are selected according to the situation.

Rongsheng Refractories Factory

Rongsheng Refractories Factory

WeChat

Scan the QR Code with wechat