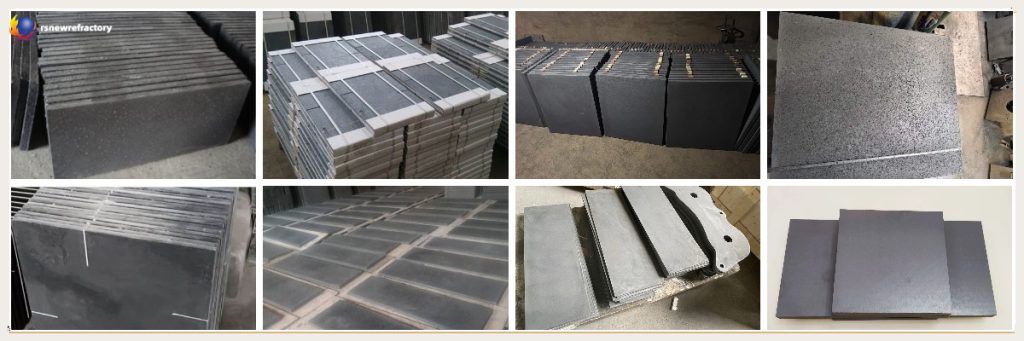

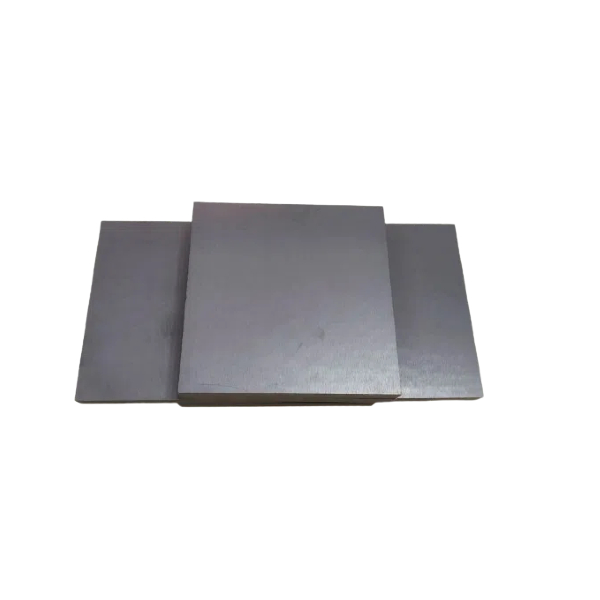

산화물 결합 SiC 내화판 가마 가구는 고품질 탄화 규소를 원료로 만들어집니다., 오산화바나듐으로, 탄산바륨, 메틸셀룰로오스, 그리고 다른 바인더가 추가되었습니다, 고압 성형, 1470℃에서 소결. 산화물 결합 탄화 규소 가마 가구는 팽창 계수가 작습니다., 좋은 열 전도성, 내산화성, 고온 저항, 내식성, 내마모성, 그리고 긴 서비스 기간. 다양한 일상용 도자기에 널리 사용됩니다., 위생 도자기, 고전압 전기 세라믹, 전자 도자기, 그라인딩 휠, 자성 재료, 및 기타 산업, 터널 가마에 적합, 셔틀 가마, 롤러 가마, 푸시 플레이트 가마, 등.

탄화규소 판의 특징

- 탄화 규소 플레이트는 작동 온도 범위가 넓습니다.. 작동 온도 범위는 약 800℃-1400℃입니다.;

- 열전도율이 높으면 가마 성능이 저하될 수 있습니다.;

- 매우 높은 열전도율, 우수한 고온 침식 저항, 우수한 내마모성.

- 열충격 저항성이 뛰어나며 극도로 춥고 더운 작업 환경 변화에도 쉽게 파손되지 않습니다.;

- 고밀도, 부드러운 표면, 사용 중 슬래그 없음;

- 강한 적응성, 세라믹 생산의 산화 분위기와 환원 분위기에 적응할 수 있습니다.;

- SIC 내화물 가마 도구는 강도가 높습니다., 긴 수명, 회전 시간은 약 500-1000 타임스.

SiC 내화판 원료 적용

실리콘 카바이드 네 가지 주요 응용 분야가 있습니다: 기능성 도자기, 고급 내화 재료, 연마재, 및 야금 원료.

⑴ 연마재로서, 연삭 도구를 만드는 데 사용할 수 있습니다., 그라인딩 휠과 같은, 유석, 그라인딩 헤드, 모래 타일, 등.

⑵ 야금탈산제 및 내열성 재료로서.

⑶ 고순도 단결정으로 반도체, 탄화규소 섬유 제조 가능.

탄화규소 판의 적용

도자기 산업

탄화 규소 플레이트는 세라믹 산업에서 광범위한 응용 분야를 가지고 있습니다.. 그들은 종종 연삭 휠을 생산하는 데 사용됩니다., 에나멜 및 전기 절연체와 같은 세라믹 코팅, 매일 도자기, 건축 도자기, 유리 및 제지 공정, 노즐 포함, 노즐, 가마 가구, 및 사이클론 분리기 구성 요소.

야금 산업

이상 65% 전 세계 대형 용광로 중 80%가 탄화규소 소재를 사용, 용광로의 수명을 최대로 연장 40%. 이러한 재료는 알루미늄을 제련할 때 용광로 라이닝이나 도가니로 널리 사용됩니다., 구리, 그리고 아연. 게다가, 질화 규소 플레이트는 전기로에서 강철의 온도를 측정하기 위한 침지 열전대 팁을 제조하는 데 사용할 수 있습니다.. 더 많은 사례를 알고 싶다면, KERUI 핀터레스트를 방문해주세요.

화학 산업

화학산업에서는, 세라믹 열교환기는 가스나 액체를 예열하여 다양한 용광로에서 폐열을 회수하는 데 자주 사용됩니다.. 탄화규소 내화판은 우수한 열적 특성과 고온 강도를 지닌 효율적인 열교환 재료로 사용될 수 있습니다.. 탄화규소는 강철보다 열전도율이 3배 더 높습니다., 최대 1400°C의 온도 측정을 위한 열전대 보호 튜브 제조에 이상적인 소재입니다..

에너지 산업

카보런덤 플레이트는 환경 열 교환기로 폭넓게 응용됩니다.. 고온 정제된 석탄가스를 가스터빈 발전에 직접 활용, 발전 효율을 크게 향상시키고 유해한 배출을 줄입니다..

여과 시스템

실리콘 카바이드 플레이트는 고성능에서 중요한 역할을 합니다., 고온 입자 제어 세라믹 여과 시스템. 이러한 시스템은 첨단 화석 연료의 사용을 촉진할 뿐만 아니라 다른 고온 산업 공정에서도 큰 응용 가능성을 가지고 있습니다., 폐기물 소각, 및 기타 분야. Kerui Refractory Company는 최고의 품질과 서비스를 제공하겠습니다..

Rongsheng 내화물 공장

Rongsheng 내화물 공장

위챗

위챗으로 QR코드 스캔