알루미나 마그네시아 탄소 벽돌, AMC 벽돌이라고 함, 마그네시아 등 여러 원료로 만들어진 불연성 내화물입니다., 고알루미나 응집체, 및 탄소재료를 분쇄하여, 혼입, 조형, 그리고 건조. 알루미늄 마그네슘 탄소 벽돌. 가열 과정 중, 스피넬은 재료의 잔류 열팽창이 양호하도록 형성됩니다., 안감 벽돌 만들기’ 접합부가 조밀하고 슬래그 침투가 감소함.

AMC 벽돌의 물리적, 화학적 지표

| 안건 | 색인 | ||||

| LMT75 | LMT70 | LMT65 | LMT60 | LMT55 | |

| 알2영형3 % | ≥75 | ≥70 | ≥65 | ≥60 | ≥55 |

| 알2영형3+MgO % | ≥81 | ≥77 | ≥80 | ≥75 | ≥72 |

| 씨 % | ≥5 | ≥5 | ≥7 | ≥7 | ≥8 |

| 겉보기 다공성 % | 7 이하 | 7 이하 | 7 이하 | 7 이하 | 7 이하 |

| 벌크 밀도 g/cm3 | ≥3.2 | ≥3.15 | ≥3.1 | ≥3.0 | ≥2.9 |

| 냉간 분쇄 강도 MPa | ≥60 | ≥60 | ≥60 | ≥50 | ≥50 |

알루미늄 마그네시아 탄소 벽돌의 특징

- 스피넬화된 팽창은 용융 철 침투에 대한 높은 저항력을 제공합니다..

- 우수한 슬래그 저항성 (스피넬은 FeO 고용체를 흡수합니다., Al2O3는 슬래그 내 CaO를 흡수하여 기공을 막고 용융점도를 증가시킵니다.).

- 높은 기계적 강도.

알루미늄 마그네슘 탄소 벽돌의 적용

알루미나 마그네시아 탄소 벽돌은 주로 국자 벽과 바닥에 사용됩니다.. 래들 내화물은 고온 저항 요구 사항을 충족해야 합니다., 열 충격 저항, 슬래그 침식 저항, 충분한 고온 기계적 강도, 내화물은 특정한 팽창 특성을 가져야 합니다.. 알루미나-마그네시아-탄소 벽돌은 이러한 국자 벽돌의 표준을 충족할 수 있습니다., 그리고 생산과정도 간단해요, 물리화학적 특성이 우수하다, 그리고 환경에 오염이 없습니다. 그것은 또한 다양한 야금 용광로 및 가마에서 널리 사용됩니다..

알루미늄 마그네시아 탄소 벽돌 공급 업체

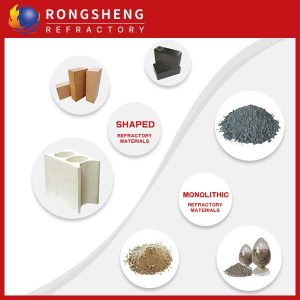

우리는 내화재료 공급업체입니다., 공급할 수 있는 것 마그네시아 다루기 힘든 벽돌, 커런덤 벽돌, 단열벽돌, 높은 알루미나 벽돌, 및 기타 형태가 없는 내화물.

인증서 쇼

우리의 고객

Rongsheng 내화물 공장

Rongsheng 내화물 공장

위챗

위챗으로 QR코드 스캔