タジキスタンへのシリコンムライトレンガの販売

7月にシリコンムライトレンガのバッチをタジキスタンにエクスポートします 2023, 合計契約価値は191,711.20米ドルです. 7月の初めに, 耐火レンガ工場は生産を完了し、シリカムライトレンガを正常に出荷しました.

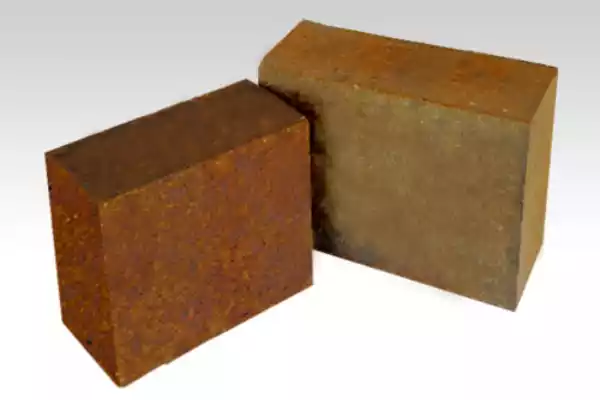

シリカレンガの原料組成

シリカムライトのレンガは、主に高アルミナボーキサイトを原料として使用しています, 白いコランダムを追加します, サブホワイトコランダム, ブラウンコランダム, シリマナイト, アンダルサイト, 粘土パウダー (広東白粘土, 蘇州土壌), シリコンマイクロパウダー, ワックスストーンパウダー, メタルはいパワー, そしてアルパウダー, 生の高アルミナボーキサイトパウダー, その他の原材料.

シリコンムライトレンガvsマグネシアアルミナスピネルレンガ

マグネシアアルミナスピネルレンガもセメントkiで使用できます. と比較して マグネシア - アルミナスピネルレンガ, シリカムライトレンガのコストパフォーマンスは高くなっています, より低い熱伝導率, そして、より良い熱安定性; マグネシア - アルミナスピネルレンガは、耐食性が優れており、熱伝導率が高くなります.

セメントキルン用のシリカムライトレンガ

タジキスタンの顧客は、セメントキルンでそれを使用しています. シリコンムライトレンガは、主に遷移ゾーンで使用されています, トロピカルゾーン, とフィーダー. シリカムライトレンガは、セメントkiのほとんどの部分で使用できます.

タジキスタンの顧客フィードバック

このタジキスタンの顧客と協力したのはこれが初めてです. 顧客は、私たちの生産効率に非常に驚きました. 配送速度は契約日より3日早かった. これにより、建設期間が狭くなり、セメントキルンプロジェクトをスムーズに完了できるようになります。. シリコンムライトレンガの品質は専門的にテストされており、使用基準を満たしています.

私たちに連絡する方法?

Rongshengはサプライヤーです 20 耐火性生産の長年の経験. あなたはウェブサイトの連絡先情報から私たちに連絡することができます, または、記事の下部にあるフォームに記入してください. 連絡先情報を残した後, できるだけ早く連絡を取ります.

栄勝耐火物工場

栄勝耐火物工場

微信

wechatでQRコードをスキャンしてください