Semi-Silicaレンガは、アルミナを備えたアルミニウムケイ酸塩耐火物製品です (Al2O3) の内容 15-30%, そして、半acidic難治性レンガです. セミシリカレンガは通常、石英砂を含む耐火性粘土を使用します, Pyrophyllite, 耐火粘土, または原材料としてのカオリンの受益尾部. 射撃中は、セミシリカのレンガが縮小しません, 1250°Cで, 原料の石英はクリストバライトに変換されます, ボリュームが拡大します, 粘土焼結の間に生成された収縮を部分的に相殺します. 半シリカレンガの製造プロセスは、2つのタイプに分けることができます: 解雇または解雇されなかった. 発射レンガの製造プロセスは、基本的に粘土レンガのプロセスと同じです; 噴火のレンガは、ほとんどがバインダーとしてウォーターグラスでできています.

セミシリカレンガの詳細

| 製品名 | セミシリコンレンガ |

| AI2O3/% | 21.59 |

| SIO2/% | 76.58 |

| fe2o3/% | 0.83 |

| 屈折器℃ | 1630-1650 |

| バルク密度g/cm³ | 2.1 |

| 見掛け気孔率 % | 18 |

| 通常の温度圧縮強度 / MPa | 29 |

| 柔らかい温度を積み込みます(T6.6) / ℃ | 1490 |

半シリカレンガの特徴

耐火性: 半シリカレンガの耐摩耗性は、通常1580°Cから1680°Cの間です.

耐薬品性: 酸性およびアルカリ性のスラグに対して良好な腐食抵抗があります.

熱安定性: 熱の安定性が良好で、温度変動が大きい環境に適しています.

Semi-Silicaブリックアプリケーション

半シリカレンガは、高温で体積が安定しています (わずかに拡張されました), 石積みの完全性を改善し、石積みのスラグの侵食を減らすのに有益です; 高温スラグと接触している場合, 粘性gl薬のような物質の層がレンガの表面に形成されます, 毛穴をブロックし、スラグがレンガに侵入するのを防ぐ, それにより、レンガの排出防止能力が向上します; そして、負荷変形温度は比較的高くなっています; したがって、場合によっては, そのサービスライフは普通の粘土レンガの生活よりも劣りません.

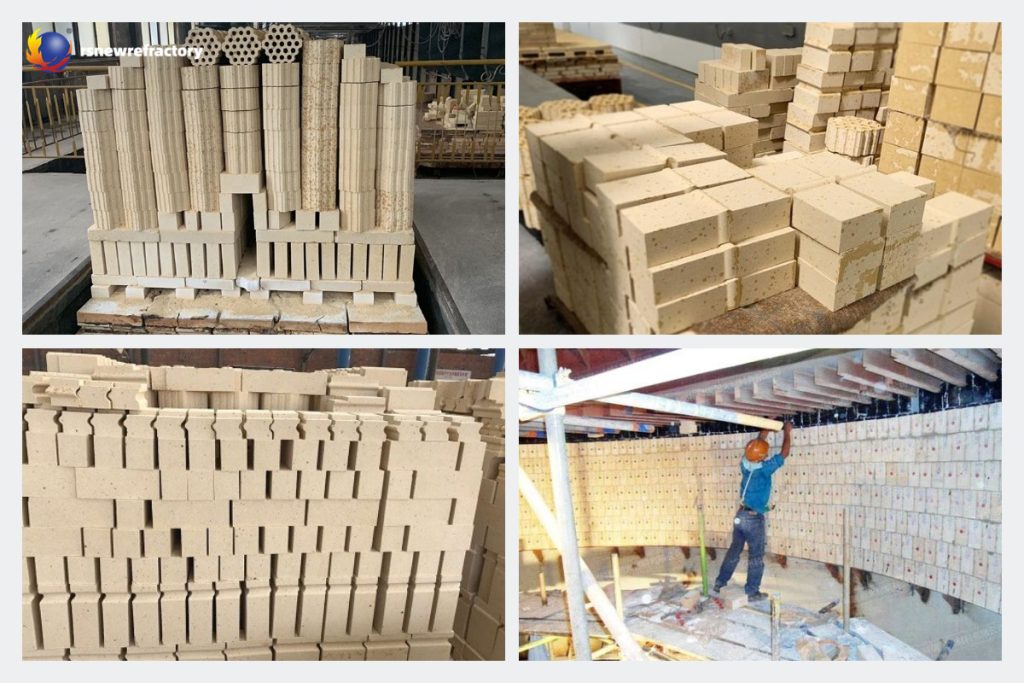

セミシリカレンガは、主に鋼のひしゃくの裏地として使用され、鋼システムを注ぐための耐火層として使用されます. 加えて, また、熱い炉の屋根にも使用できます, 再生者チェッカーレンガ, キューポラの裏地, 各種窯底・煙道.

セミシリカレンガ工場の生産プロセス

- 原材料の選択: シリコンとアルミニウムの含有量が高い原材料を選択します, 粘土や石英など.

- 混合と均質化: 原料を混合して均質化して、成分の均一な分布を確保する.

- 成形: プレスや押し出しなどの成形方法を使用して、必要な形状のレンガを作る.

- 乾燥: レンガは乾燥室で乾燥して水分を除去します.

- 発砲: トンネルキルンまたはシャトルキルンでの高温発火して、ハードセミシリカレンガを形成する.

- 検査とグレーディング: 発射された半シリカレンガの品質が検査され、サイズに応じて等級付けされます, 外観, そしてパフォーマンス.

栄昇の会社紹介

Rongsheng Company は耐火物材料の専門サプライヤーです。, と 10 長年の輸出経験, 以上にエクスポートしています 80 国. Rongsheng Company の主な製品には、さまざまな耐火レンガが含まれます。, 不定形耐火物, 冶金材料, 断熱材など.

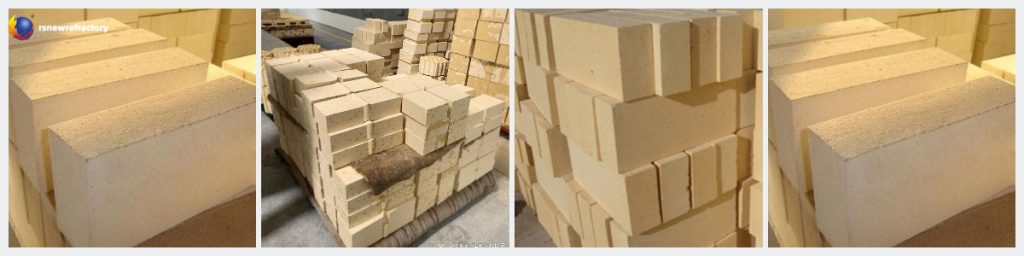

栄勝耐火物工場

栄勝耐火物工場

微信

wechatでQRコードをスキャンしてください