栄勝耐火物へようこそ! 耐火物メーカーの世界的トップサプライヤーとして, 私たちは高品質の製品を提供することに尽力しています 耐火製品 あらゆる分野への専門的な耐火物技術サービスを提供します. 鉄鋼に最適な耐火物をご提案します, ガラス, セラミックス, セメント, 石油化学, 力, またはその他の高温産業.

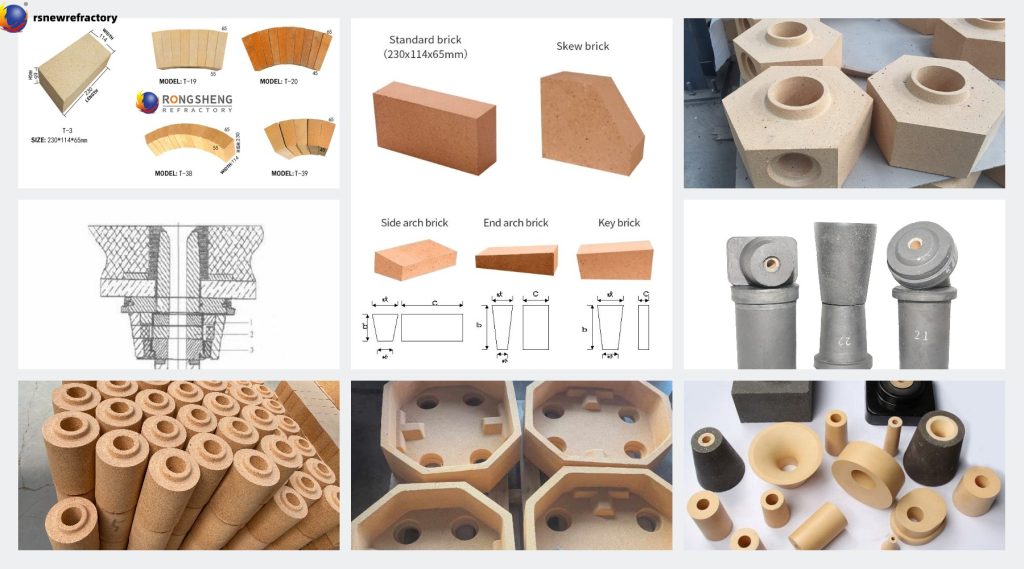

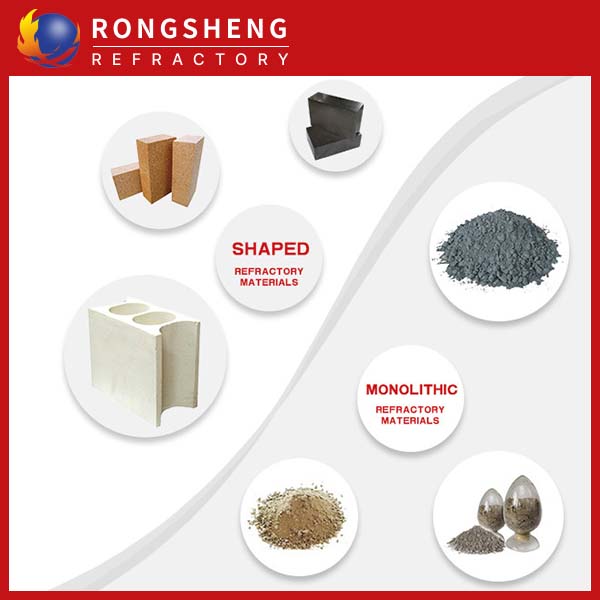

選べる耐火物製品

高温耐火レンガ

数百種類の異なる耐火レンガからお選びいただけます. 窯温度や使用環境に応じて、適切な耐火レンガのご提案もさせていただきます。. 以下にいくつかの人気のある耐火レンガを示します.

| 高アルミナ耐火レンガの物理的および化学的指数: | ||||||

| アイテム | プロパティ | |||||

| RS-80 | RS-75 | RS-65 | RS-55 | RS-48 | ||

| Al2O3(%) | 80 | 75以上 | 65以上 | ≥55 | ≥48 | |

| 耐火性(℃ ) | ≥1790 | ≥1790 | ≥1790 | ≥1770 | ≥1750 | |

| かさ密度(グラム/センチメートル3) | 2.65 | 2.5 | 2.45 | 2.4 | 2.3 | |

| 負荷時の軟化温度(℃ ) | 1530 | ≥1520 | ≥1500 | ≥1470 | ≥1420 | |

| 再加熱率の線形変化 (%) | 1500°CX2H | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

| 1450°CX2H | -0.4 | -0.4 | -0.4 | -0.4 | -0.4 | |

| 見かけの気孔率 (%) | 22 | ≤23 | ≤23 | ≤22 | ≤22 | |

| 冷間圧壊強度 (メガパスカル) | 55 | 50以上 | ≥45 | 40以上 | ≥35 | |

| 応用 | 鋼鉄炉, ガラス炉, ケイ酸ナトリウム炉, セラミックシャトル窯, セメントロータリーキル, 高炉, 電気炉, 高炉と反射炉. | |||||

マグネシアカーボン煉瓦

- 良好な高温耐性.

- 強い耐スラグ性.

- 優れた耐熱衝撃性.

- 高温での低クリープ.

- 低い熱膨張率, 変形しにくい.

- 剥がれにくい.

| マグネイサ カーボン ブリック | ||||||

| 項目/索引 | MGC-10 | MGC-12 | MGC-15 | MGC-18 | MGC-20 | |

| かさ密度 (g/cm3) | 2.95 | 2.90 | 2.85 | 2.80 | 2.78 | |

| 見かけの気孔率 (%) | 3~5 | 3~5 | 3~5 | 3~5 | 3~5 | |

| 圧縮強度 (kg/cm2) | 450 | 400 | 400 | 350 | 350 | |

| での拡張 1000 ℃ | 1.20 | 1.20 | 1.20 | 1.20 | 1.20 | |

| 化学組成 (%) | MgO | 86 | 84 | 80 | 76 | 74 |

| FC. | 10 | 12 | 15 | 18 | 20 | |

| 応用 | 柄杓 | EAFLadle | BOFEAFお玉 | ボフィーフル | ボフィーフ | |

AZSブリック

1. 高温耐性, 高強度, さまざまな窯で広く使用されています

2. 高純度、高アルミニウム含有原料

3. 低い熱伝導率. 優れた熱安定性と耐食性

4. サイズは正確でカスタマイズ可能です.

| アイテム | 溶融鋳造AZSレンガ | |||

| 索引 | RS-AZS33 | RS-AZS36 | RS-AZS41 | |

| 化学薬品 構成% | Al2O3 | ≥50.00 | ≥49.00 | ≥45.00 |

| ZrO2 | ≥32.50 | ≥35.50 | ≥40.50 | |

| SiO2 | ≤15.00 | ≤13.50 | ≤12.50 | |

| Na2O+K2O | ≤1.30 | ≤1.35 | ≤1.30 | |

| 体積密度 g/cm3 | ≥3.75 | ≥3.85 | ≥4.00 | |

| 見掛け気孔率 % | ≤1.2 | ≤1.0 | ≤1.2 | |

| 冷間圧砕強度Mpa | ≥200 | ≥200 | ≥200 | |

| ガラス相の浸出温度 | ≥1400 | ≥1400 | ≥1410 | |

| 気泡分離率(1300℃×10h) | ≤1.2 | ≤1.0 | ≤1.0 | |

| ガラス液の耐食率 1500℃×36h(mm/24h)% | ≤1.4 | ≤1.3 | ≤1.2 | |

| かさ密度(g/cm3) | 普通鋳造PT(RN RC N) | ≥3.55 | ≥3.55 | ≥3.70 |

| 収縮しない鋳物 ZWS(RR EVF EC ENC) | ≥3.65 | ≥3.75 | ≥3.85 | |

| ティルトキャスティングQX(RO) | ≥3.65 | ≥3.75 | ≥3.90 | |

| 無収縮鋳造WS( RT VF EPIC FVP DCL) | ≥3.75 | ≥3.80 | ≥3.95 | |

炭化ケイ素ムライト煉瓦

耐食性

耐摩耗性

耐熱衝撃性

良好な熱伝導性

| アイテム | GM1650 | GM1600 | GM1550 | GM1680 |

| Al2O3 % | 63 | 60 | 57 | 63 |

| SiO2+SiC % | 30 | 30 | 30 | 30 |

| 見かけの気孔率 % | 17 | 17 | 19 | 17 |

| 冷間圧壊強度Mpa | 85 | 90 | 90 | 100 |

| 荷重耐火度 ℃ (0.2メガパスカル) | 1650 | 1600 | 1550 | 1680 |

| 耐熱衝撃性(11oo℃, 水冷) | 10 | 10 | 12 | 13 |

| かさ密度 g/cm3 | 2.65 | 2.60 | 2.55 | 2.65 |

| 冷間摩耗抵抗cm3 | 5 | 5 | 5 | 5 |

| 熱伝導率(w/m・k) | 1.7 | 1.7 | 1.7 | 1.7 |

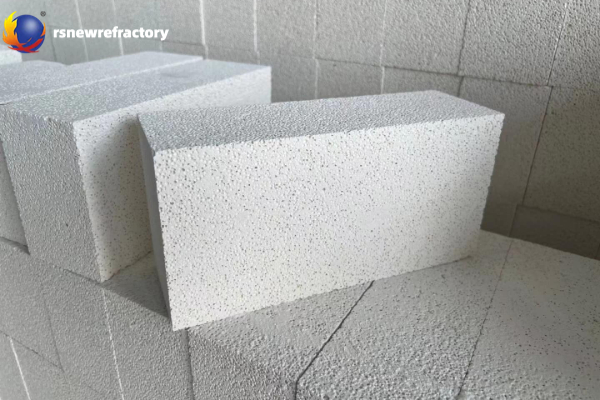

断熱レンガ

ムライト断熱レンガ

- 低熱融着

- 低い熱伝導率

- 高耐火性

- 優れた化学的安定性

- 高い圧縮強度と曲げ強度

- 正確な外観とサイズ

| ムライト断熱レンガ | ||||||

| 項目/索引 | RS23 | RS26 | RS28 | RS30 | RS32 | |

| Al2O3 % | 37 | 54 | 64 | 72 | 77 | |

| Fe2O3 % | 1.0 | 0.9 | 0.8 | 0.7 | 0.5 | |

| 熱伝導率 (w/m*k) | 400℃ | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

| 600℃ | 0.16 | 0.29 | 0.34 | 0.43 | 0.5 | |

| 800℃ | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

| 1000℃ | 0.20 | 0.33 | 0.38 | 0.45 | 0.53 | |

| 分類温度 (℃) | 1260 | 1430 | 1540 | 1650 | 1760 | |

| 熱膨張1000℃ (%) | 0.5 | 0.7 | 0.8 | 0.9 | 1.1 | |

| かさ密度 (g/cm3) | 0.55-0.62 | 0.78-0.8 | 0.88 | 1.03 | 1.25 | |

| 冷間圧砕強度 (メガパスカル) | 1.2 | 1.6 | 2.1 | 2.5 | 3.5 | |

| 破壊係数 (メガパスカル) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

| 再加熱の線形変化 (%)CT-30℃*8H | 1230℃-0.5 | 1400℃-0.5 | 1510℃-0.5 | 1620℃-0.9 | 1730℃-0.9 | |

不定形耐火物

不定形耐火物, バルク耐火物または非晶質耐火物としても知られています。, 焼成によって形成されない耐火物を指します。. 従来の形状耐火レンガとは異なります。, 非構造耐火物には固定された形状やサイズがありません. 通常、それらは粉末の形で存在します, 顆粒, 泥, または繊維. 使用時, 直接注がれます, 体当たりした, スプレーされた, 適用済み, またはニーズに応じて建設現場で充填されます.

低および超低セメント キャスタブル

- 高耐火性, 高温, 耐低温性

- 耐浸食性, 耐衝撃性, 高い耐摩耗性, 高強度

- 強い可塑性, あらゆる形状に鋳造できます

- 気密性が良い, 熱損失を減らし、エネルギーを節約できます

| メートル | 超低セメントキャスタブル | |||

| 材料 | 粘土 | 高アルミナ | コランダム | |

| かさ密度 (g/cm3) | 2.35 | 2.70 | 3.20 | |

| Al2O3(%) | 45 | 75 | 95 | |

| 曹操(%) | 1.15 | 1.15 | 1.15 | |

| 曲げ強度(メガパスカル) | 110℃×16h | 6 | 6 | 8 |

| 1500℃*3h | 8 | 8 | 10 | |

| 圧縮強度(メガパスカル) | 110℃×16h | 40 | 40 | 60 |

| 1500℃*3h | 70 | 800 | 90 | |

| 書き込み後のライン変化率(%) | 110℃×16h | -0.1 | 0 | 0 |

| 1500℃*3h | +-0.5 | +-0.5 | +-0.5 | |

| 耐火性 | ℃ | 1710 | 1790 | 1790 |

| 安全な使用温度 | ℃ | 1400 | 1450 | 1650 |

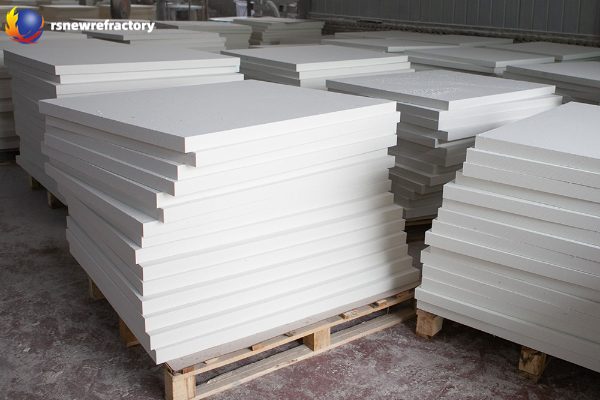

セラミックファイバー製品

その他の耐火物製品のカスタマイズ

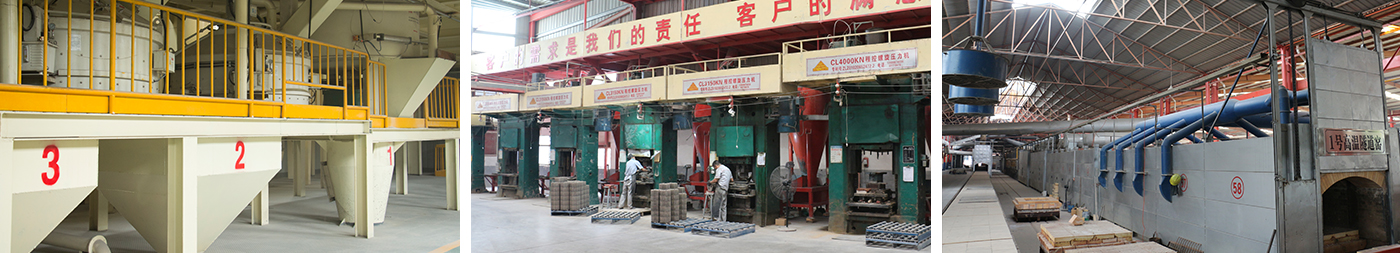

耐火物製品の製造

耐火物メーカー’ お客様の事例

後 20 長年の蓄積, 当社には複数の業界や国をカバーする多くの成功した顧客がいます. 例えば, 製鉄所向けに高アルミナれんがを提供しています, ガラスプラント用の高温耐性ジルコンレンガをカスタマイズする, 鋳物工場向けにさまざまな耐火物製品を提供します. 当社の製品はお客様から高い評価と信頼をいただいております.

栄勝耐火物工場

栄勝耐火物工場

石レンガを探しています

4. × 9. ×. 1 1/4

7807140474

お問い合わせいただきありがとうございます. 当社の営業チームがプロジェクトについて話し合うためにご連絡いたします.