Le principali materie prime del cancello della slitta del mestolo sono carbonio in alluminio e carbonio di zirconio in alluminio. La necessità di un acciaio speciale rende diversificata lo sviluppo di porte di diapositiva. Il mattone a piastra scorrevole presenta i vantaggi di un'elevata resistenza al fuoco, buona stabilità chimica, resistenza alla corrosione di scorie e metalli liquidi, Buona resistenza all'ossidazione, e resistenza alla scheggiatura.

Morto Slide Gate Fisiche e chimiche Indicatori

Indicatori fisici e chimici:

| Articolo | Indice | |||

| HBLT80 | HBLT75 | HBLT70 | ||

| Al2O3 % | ≥80 | ≥75 | ≥70 | |

| C % | ≥2 | ≥3 | ≥3 | |

| Resistenza allo schiacciamento a freddo MPa | Non impregnazione | ≥80 | ≥70 | ≥60 |

| Impregnazione | ≥100 | ≥90 | ≥80 | |

| Porosità apparente % | Nonimpregnazione | ≤13 | ≤13 | ≤13 |

| Impregnazione | ≤10 | ≤10 | ≤10 | |

| Densità apparente g/cm3 | Nonimpregnazione | ≥2,9 | ≥2,85 | ≥2,75 |

| Impregnazione | ≥2,95 | ≥2,9 | ≥2,85 | |

Alluminio Zirconio Carbonio:

| Articolo | Indice | ||||

| HBLTG80 | HBLTG75 | HBLTG70 | HBMLT80 | ||

| Al2O3 % | ≥80 | ≥75 | ≥70 | / | |

| Al2O3+MgO % | / | / | / | ≥80 | |

| C % | ≥3 | ≥3 | ≥4 | ≥3 | |

| ZrO2 % | ≥4 | ≥4 | ≥4 | / | |

| Porosità apparente % | Nonimpregnazione | ≤13 | ≤13 | ≤13 | ≤13 |

| Impregnazione | ≤10 | ≤10 | ≤10 | ≤10 | |

| Densità apparente g/cm3 | Non impregnazione | ≥3.0 | ≥2,95 | ≥2,9 | ≥2,75 |

| Impregnazione | ≥3.05 | ≥3.0 | ≥2,95 | ≥2,8 | |

| Resistenza allo schiacciamento a freddo MPa | Non impregnazione | ≥90 | ≥90 | ≥80 | ≥70 |

| Impregnazione | ≥110 | ≥110 | ≥100 | ≥90 | |

La funzione del cancello della slitta del mestolo

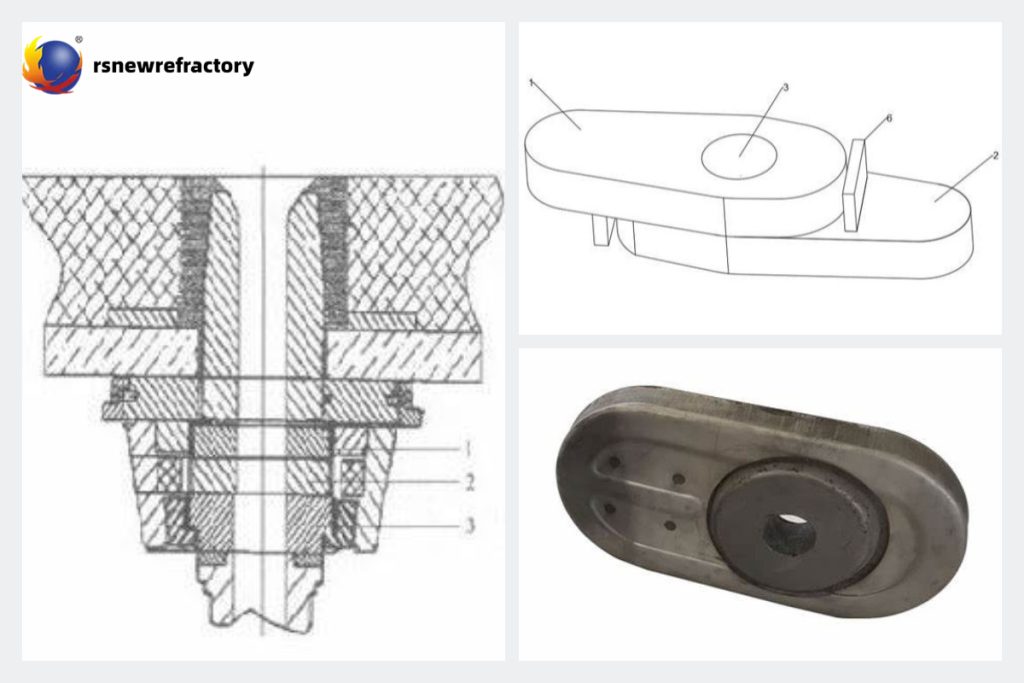

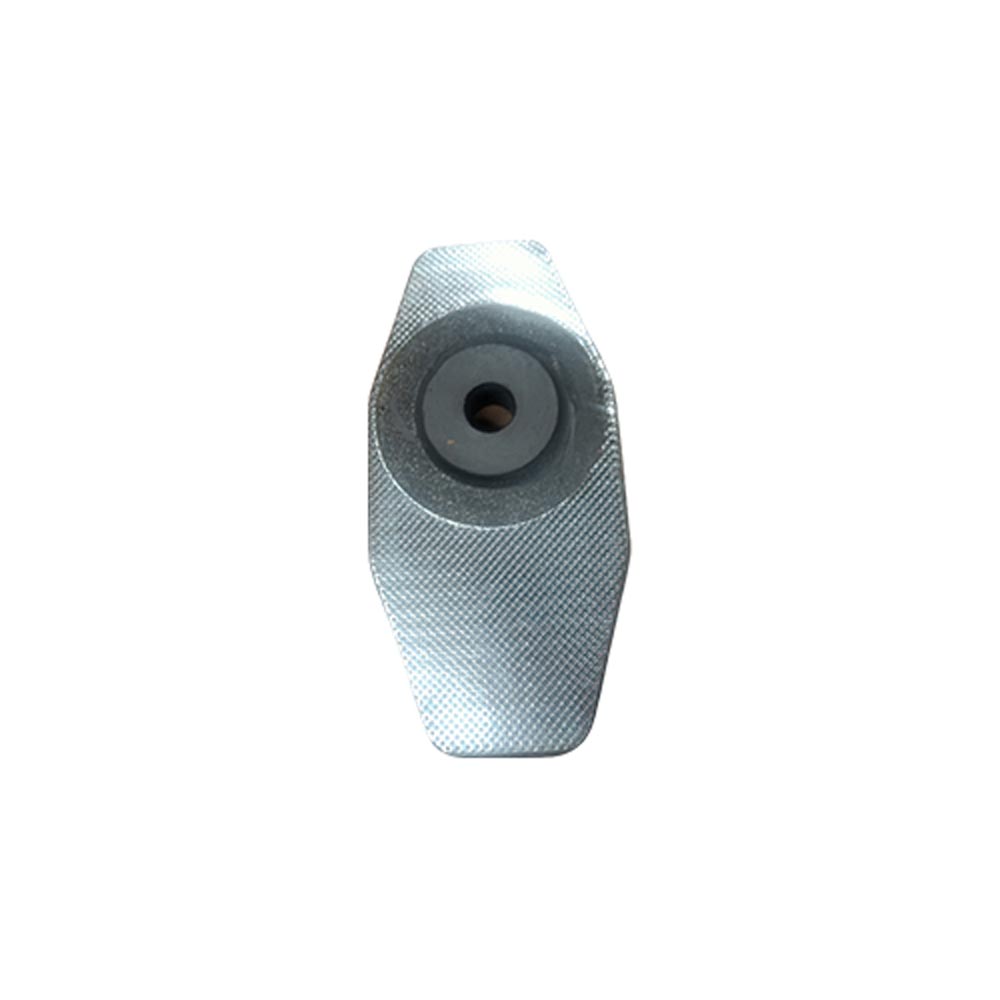

La vetrina è un componente essenziale nel processo di fabbricazione dell'acciaio. Viene utilizzato per controllare il flusso di acciaio fuso dal mestolo al Tundish durante la fusione continua. Lo slitta è un materiale refrattario progettato per resistere a temperature elevate e sollecitazioni meccaniche.

La vetrina è costituita da vetrini superiori e inferiori, un meccanismo scorrevole e un guscio. I vetrini superiori e inferiori sono realizzati con materiali refrattari di alta qualità come allumina o ossido di magnesio e sono progettati per adattarsi strettamente per formare una tenuta. Il meccanismo di scorrimento è responsabile dell'apertura e della chiusura del cancello per consentire all'acciaio fuso di fluire attraverso il mestolo.

Un sistema scorrevole gestisce la diapositiva per consentire all'acciaio fuso di fluire attraverso il mestolo nel Tundish. Il cancello è chiuso da un processo di inversione, Spingendo la piastra superiore indietro sulla piastra inferiore per formare una guarnizione stretta. La vetrina può controllare accuratamente il flusso di acciaio fuso, migliorando così l'accuratezza del riempimento dello stampo e migliorando la qualità complessiva dell'acciaio fuso prodotto, Migliorando così l'efficienza del processo di produzione dell'acciaio e riducendo i costi di produzione complessivi. Lo slitta a mestoli aiuta a prevenire incidenti e lesioni che possono verificarsi durante il processo di consegna in acciaio fuso.

Diversi materiali comuni per il cancello della diapositiva

I seguenti sono i materiali comuni per le diapositive del mestolo: Slide in alluminio elevato, Slide di carbonio in alluminio, Slide di carbonio di zirconio in alluminio, Slide di carbonio in carbonio e spinello di magnesio, e le diapositive del mestolo di zirconia.

Introduzione dell'azienda di Rongsheng

Rongsheng Company è un fornitore professionale di materiali refrattari, con 10 anni di esperienza di esportazione, esportare in più di 80 Paesi. I principali prodotti della Rongsheng Company includono vari mattoni refrattari, refrattari non formati, materiali metallurgici, materiali di isolamento termico, e così via.

Fabbrica dei refrattari di Rongsheng

Fabbrica dei refrattari di Rongsheng

WeChat

Scansiona il codice QR con wechat