Il mortaio refrattario viene trasformato in nuovi tipi di materiali di legante inorganici scegliendo gli stessi materiali in polvere e aggiungendo legante inorganico, Secondo la richiesta di materiali da costruzione. Ci sono quattro gradi sotto NT-1300, NT-1400, NT-1500, e NT-1600, Ogni materiale è diviso in leggero e pesante peso, e possiamo scegliere un malta refrattario pertinente in base a diverse richieste di materiali da costruzione.

Parametri della malta refrattaria

MgO(%) | Al2O3(%) | Cr2O3(%) | Moduli di rottura(MPa) | Refrattarietà | Tempo di legame | Contadino | ||

| ≥ | ≥ | 110℃ *24h | 1400℃ *3h | (℃) ≥ | (min) | |||

| Mortaio magnesia-cromo | 78-85 | – | 3-5 | – | 2 | 1800 | 1-3 | Bicchiere d'acqua |

| Morta composita di magnesia-cromo | 90 | – | 1-3 | – | 4 | 1800 | 1-3 | Bicchiere d'acqua |

| Mortaio di magnesia | 85-90 | – | – | – | 3 | 1800 | 1-3 | Bicchiere d'acqua |

| Mortaio spinello | 80-85 | 4-8 | – | – | 4 | 1800 | 1-3 | Bicchiere d'acqua |

| Morta di allumina alta | – | 60-75 | – | 1 | 4 | 1790 | 1-3 | Acqua |

| Mortaio di allumina elevata anti-sprepping | – | 75 | – | 1 | 5 | 1790 | 1-3 | Acqua |

| Mortaio fosfato | – | 70 | – | 1 | 5 | 1790 | 1-3 | Fosfato |

| Mortaio p901 | – | 75 | – | 1.5 | 6 | 1790 | 1-3 | Fosfato |

| Mortaio resistente alkai | – | 30-35 | – | 1 | 3 | 1690 | 1-3 | Acqua |

| Mortaio resistente alcalino isolante | – | 30-40 | – | 1 | 1.5 | 1650 | 1-3 | Acqua |

| Fango di silicio(RSGN-96) | SiO2%≥96 | 0.6 | – | 0.5 | 1.5 | 1710 | 1-3 | Acqua |

| Fango di silicio(RSGN-94) | SiO2%≥94 | – | – | 1 | 3 | 1690 | 1-3 | Acqua |

| Fango isolante al calore al silicio(RSGGN-94) | SiO2%≥94 | – | – | 0.5 | 1.5 | 1690 | 1-3 | Acqua |

| Fango isolante al calore al silicio(RSGGN-92) | SiO2%≥92 | – | – | 0.5 | 1.5 | 1670 | 1-3 | Acqua |

| Mortaio refrattario resistente all'usura | – | – | – | – | 1000℃*3 ore(4-6) | 1790 | 1-3 | Acqua |

| Mortaio refrattario leggero | – | – | – | – | – | 1650 | 1-3 | Acqua |

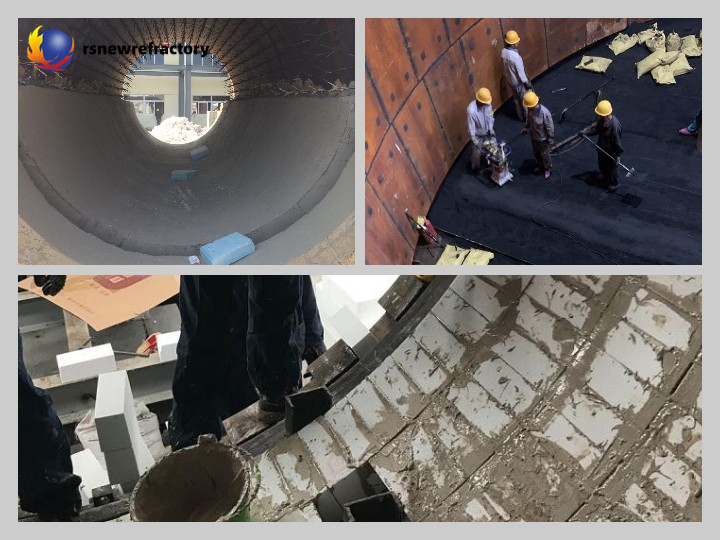

Applicazione di malta refrattaria

Le industrie di applicazione includono la metallurgia, materiali da costruzione, macchinari, petrolchimico, bicchiere, caldaie, energia elettrica, acciaio, cemento, eccetera. Il materiale della malta refrattaria deve essere coerente con quello dei prodotti refrattari per muratura. Oltre ad essere utilizzato come materiale di puntamento, il fango refrattario può essere utilizzato anche come strato protettivo per rivestimenti mediante spalmatura o spruzzatura.

Caratteristiche del mortaio ad alto calore

Sicurezza: Il mortaio non produce scintille quando colpita o sfregata, ed è particolarmente adatto per ambienti con sostanze infiammabili ed esplosive.

Resistente all'usura: Ha un'eccellente resistenza all'usura, può resistere efficacemente a vari usura, e estende la durata del pavimento.

Antiscivolo: La sua superficie è liscia e ha buone proprietà anti-slip, che può ridurre efficacemente gli incidenti.

Antistatico: Il mortaio ha buone proprietà conduttive, che può effettivamente prevenire l'accumulo di elettricità statica ed evitare potenziali pericoli.

Costruzione conveniente: Può essere aggiunto direttamente con acqua e agitato in proporzione, e l'operazione di costruzione è semplice e conveniente.

Protezione ambientale: Il mortaio non contiene sostanze chimiche dannose per il corpo umano e l'ambiente, e soddisfa i requisiti di protezione ambientale.

Processo di costruzione di malta refrattaria

- Pulizia di base. Prima di tutto, è necessario pulire la superficie della fondazione per evitare detriti come polvere galleggiante e olio.

- Superficie di costruzione bagnata. Prima dell'applicazione, utilizzare un rullo o un irrigatore per bagnare la superficie, ma non dovrebbe esserci acqua in eccesso durante l'applicazione.

- Configura i materiali. Mescola malta e acqua, e aggiungere acqua a 14-20%, a seconda della situazione reale.

- Leviga la superficie. La malta agitata viene colata sul piano di lavoro, che deve essere completato entro 20 minuti.

- Manutenzione. Cospargere d'acqua dopo la riparazione, o coprire con pellicola di plastica per la manutenzione.

Perché scegliere la compagnia refrattaria monolitica di Rongsheng

Linea di produzione completamente automatica appena aggiornata

Rongsheng ha una linea di produzione completamente automatica appena aggiornata, che può realizzare la produzione automatica di prodotti amorfi come cemento refrattario, calcinabili refrattari, malta refrattaria, eccetera., e realizzare una produzione di alta qualità ed efficiente di materiali refrattari.

Servizio di ingegnere professionale

Abbiamo un team di ingegneri esperti che possono fornire ai clienti soluzioni refrattarie professionali per garantire il miglior utilizzo dei prodotti.

Forte capacità di fornitura di fabbrica refrattaria

Rongsheng refrattario ha due fabbriche refrattarie. Rongsheng è in grado di fornire stabilmente un gran numero di prodotti refrattari monomeri. Ancora più importante, ha esportato materiali refrattari a più di 50 paesi e ha una ricca esperienza di esportazione.

Prodotti refrattari di alta qualità

Rongsheng controllerà rigorosamente la qualità del prodotto, che fornisce ai clienti un'assicurazione del prodotto di alta qualità. Allo stesso tempo, Possiamo personalizzare i materiali refrattari per i clienti.

Fabbrica dei refrattari di Rongsheng

Fabbrica dei refrattari di Rongsheng

PER 50 SACCO DA CHILI DI CASTELLO REFRATTARIO DI QUANTI LITRI DI ACQUA ABBIAMO BISOGNO+584121968090

OK,ti contatteremo il prima possibile